The OPRO Tech Engineering team includes diversified and experienced system engineers, we can support your project at every stage of development. We have demonstrated our ToolingMold, analysis, and design capabilities over many programs for the medical, household, Automotive, and commercial industries.

Our design engineers are experienced injection mold designers who are continually striving to increase the efficiency and performance of each plastic injection mold we deliver. The injection molding design process optimizes the performance of each custom plastic mold and guarantees each part made in the mold will be to specification. We design using the latest versions of many software programs including Pro-E, Solidworks, AutoCAD and more.

Design for Manufacturability (DFM)

Early involvement in part and mold design using Design For Manufacturability (DFM) Review is key to successful part and product development.

At OPRO Tech ToolingMold, we emphasize the benefits of DFM to our clients with the knowledge that this powerful diagnostic tool will create a more efficient production cycle and ultimately increase profitability.

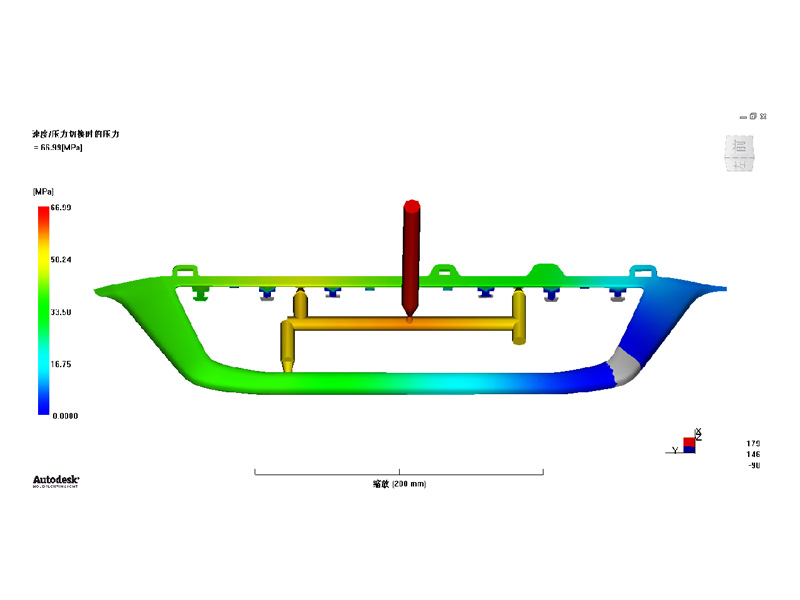

Mold Flow Analysis

By providing a truly seamless integration of part design, mold flow analysis, and mold design, we can simulate the injection molding process, optimize molding parameters, and identify potential tooling and molding problems in the early design stages.

Mold Design

By using Parametric 3D CAD mold design, we are able to employ computer aided manufacturing in a near paperless environment. Our product data management system ensures that incoming and outgoing files are tracked and managed. We utilize our ToolingMold change notice system to control and verify design revisions.

CNC Machine

Operating 24 hours, six days a week, OPRO Tech’s CNC machine is a workhorse! Our CNC machine supports all departments and project leaders. Having multiple machining centers running practically non-stop allows us to build our mold bases in-house in a short amount of time. The almost constant production of our CNC maching also provides us with the capability to deliver on demanding project deadlines. These in-house CNC capabilities set us apart from the competition.

-

Flat Surfaces — These machines are able to precisely cut and level away areas of the material and repetitively do so from one material to another to ensure tight closures.

-

Drilled Holes — Threads are carved through to make screws or bolts fit and it also bores exactly for every material.

-

Bored Holes — It follows the programmed size or diameter. So, every assembly of parts becomes precise and allows tight sealing.

Wire cut

OPRO Tech's in-house Wire cut department operates around the clock, six days a week. This almost non-stop operation enables OPRO Tech to stay on schedule and maintain quality control of our mold components and mold base.

Our Wire cut machining services are an extremely accurate method of producing a part for high quality, close tolerances. Wire cut technology is a critical aspect for advanced superior tolerance of parts, repeatable and extensive tooling with ultra fine finishes.

Materials Utilized in Wire cut Machining

-

Stainless Steel-corrosion resistant Wire cut parts machining

-

Titanium-for unique Wire cut machining

-

Steel & Hard Tool Steels for Wire cut Service

-

Copper-for conductive Wire cut Service

-

Aluminum-for resisting corrosion in EDM parts

-

Hastaloy-high-performance alloys used in EDM

-

Kovar-for mechanical conductivity

-

Carbide-used in Wire cut industrial applications

-

Inconel-for high temperature Wire cut machining

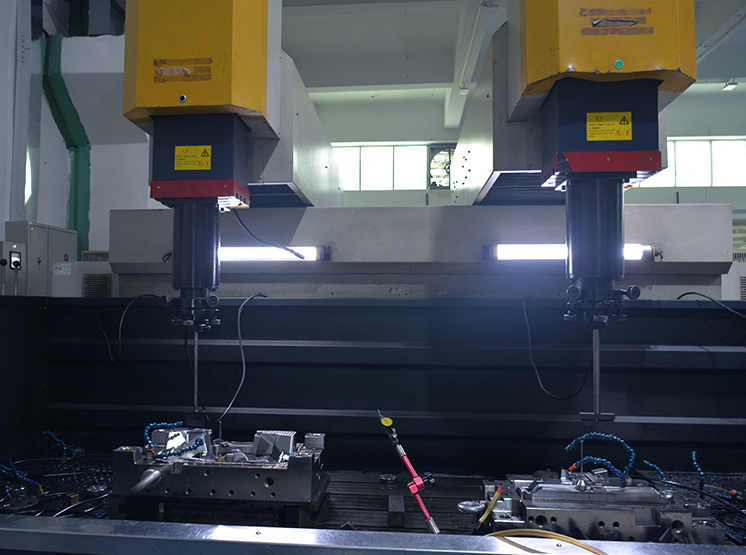

EDM

Electrical Discharge Machining (EDM) with two heads, often referred to as "twin-head EDM," is a variation of the traditional EDM process that involves the simultaneous use of two electrode heads. EDM is a non-traditional machining method where material is removed from a workpiece using electrical discharges or sparks. The two heads in twin-head EDM can operate independently or synchronously. We have two twin-head EDM.

-

Simultaneous Machining

-

Increased Efficiency

-

Complex Geometries

-

Parallel Operations

-

Independent Control

-

Improved Accuracy

-

Reduced Cycle Time

-

Versatility

Coordinate Measuring Machine (CMM) is a sophisticated metrology device used in manufacturing and quality control processes to measure the physical geometrical characteristics of an object. CMMs are instrumental in ensuring that manufactured parts conform to design specifications, tolerances, and quality standards.

CMMs are indispensable tools in industries such as aerospace, automotive, medical, and manufacturing, where precision and quality control are paramount. Our Sweden brand CMM contributes to improving production efficiency, reducing defects, and ensuring compliance with industry standards.