Understanding Thermoplastics and Thermosets: What They Are and Why They Matter

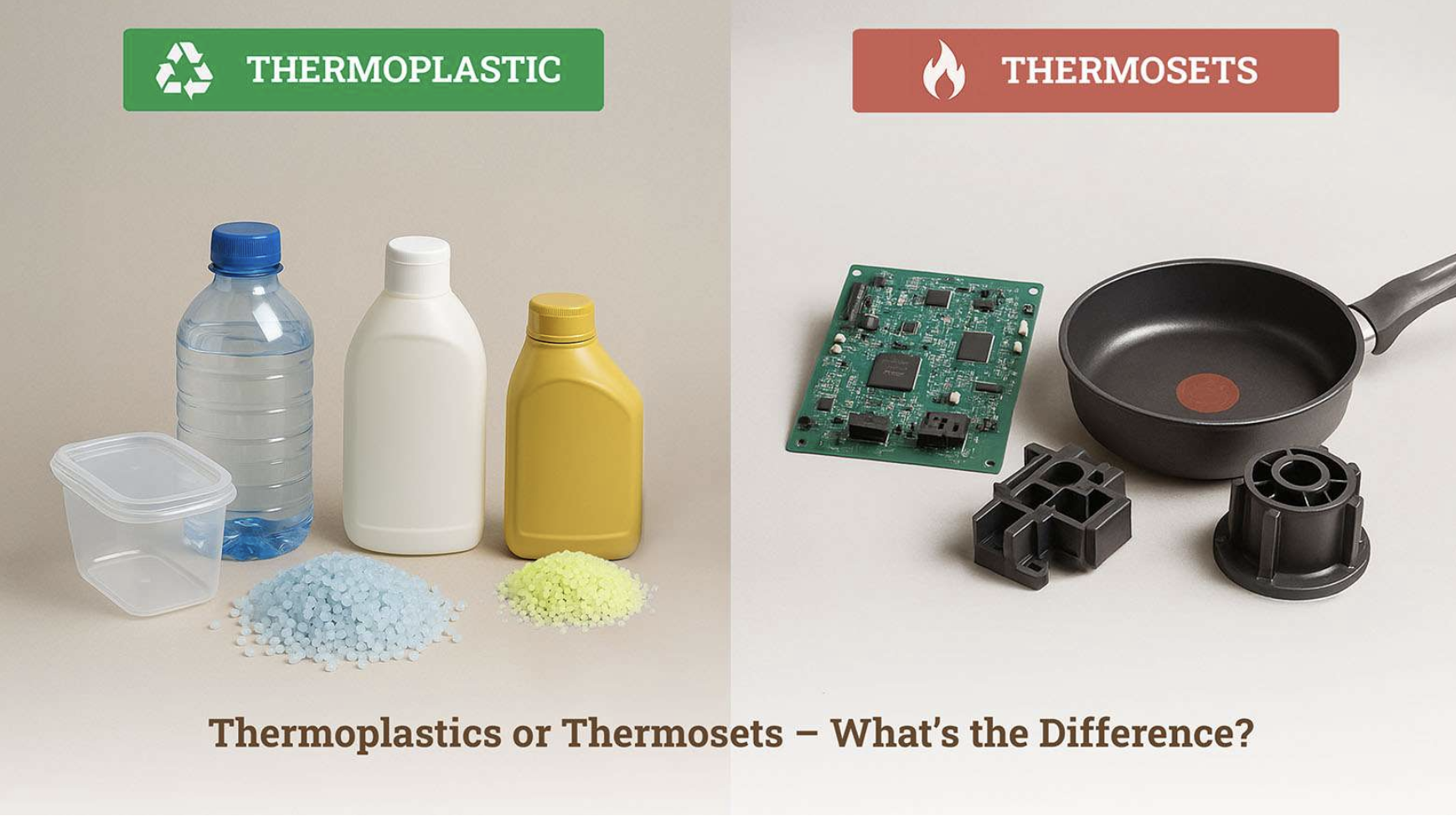

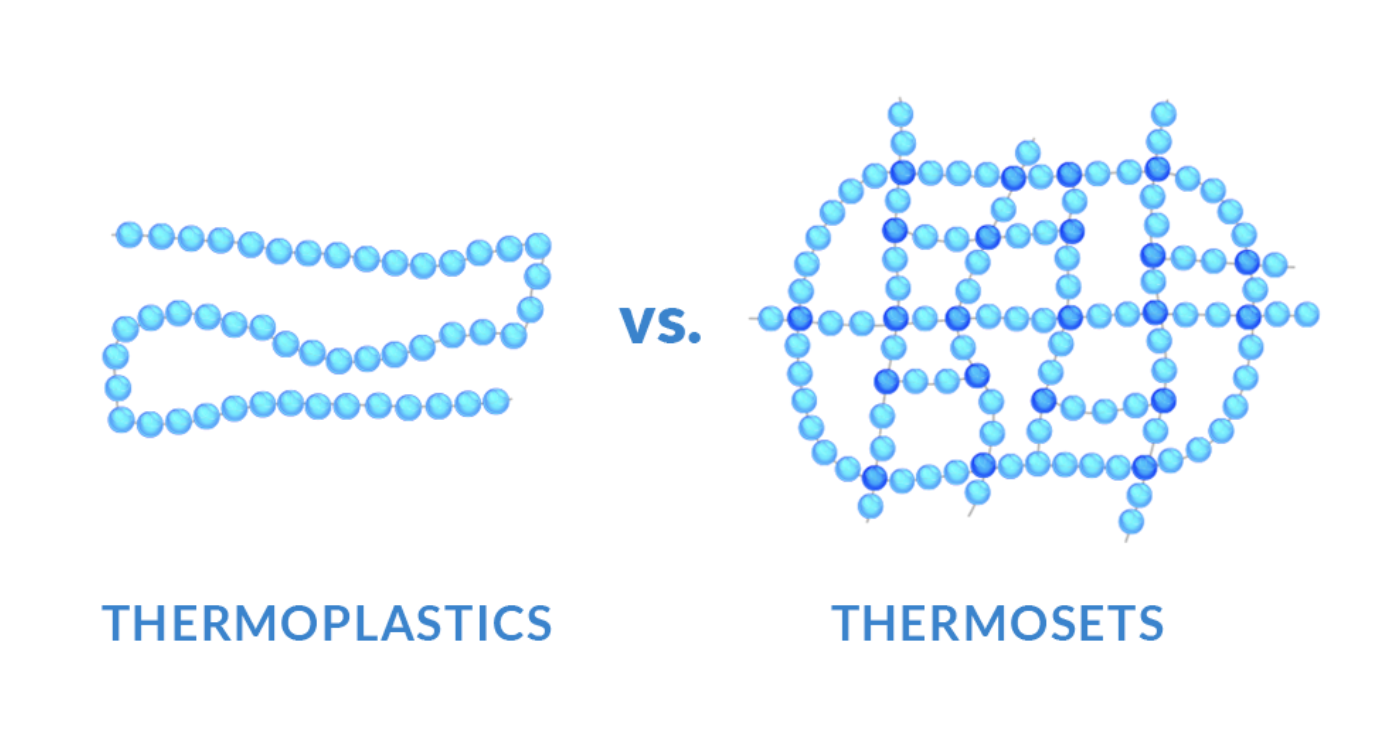

In the world of plastic manufacturing, two major categories dominate the molding process: thermoplastic materials and thermosetting materials. Though they may look similar in the final product, the way they behave under heat — and how they are processed — is fundamentally different. These differences not only affect how the parts are made but also determine their recyclability, application, and performance under stress, heat, or chemicals.

Thermoplastics are materials that soften when heated and harden when cooled, allowing them to be reshaped and recycled multiple times. This makes them highly versatile and commonly used in injection molding. Some widely used thermoplastics include ABS (impact resistant, often used in electronics), Nylon (PA) and POM (great for gears and moving parts), PC (strong and transparent, often food-safe), PP (lightweight, chemical-resistant), and PVC (rigid or flexible, mostly used for pipes and cables). Their properties vary, but what they all share is the ability to melt and remelt — which simplifies manufacturing and recycling.

🔍 Thermoplastic vs Thermosetting Materials

✅ Thermoplastics

· Can be melted and reshaped repeatedly.

· Used in injection molding.

· Examples: ABS, PC (Polycarbonate), PP (Polypropylene), PA (Nylon), PE, POM, etc.

🔑 Key Takeaways (and in general)

- ABS: Known for strength + fire retardant options (used in electronics, appliances)

- PC & PP: Commonly used for food-contact products (safe, stable, hygienic)

- PVC: Mostly for pipes, cables, window frames — strong and waterproof, but not food-grade in most forms

- Nylon (PA): Good for mechanical and moving parts, like gears and bearings — high wear resistance, some grades absorb water

- POM (Acetal): Excellent for precision parts, low friction, used in mechanical engineering — better dimensional stability than nylon

🧠 Memory Tip:

Think of them like a toolbox:

- 🛠 ABS = durable cover, shell, flame protection

- ⚙️ Nylon & POM = gears, engineering parts, moving stuff

- 🍽️ PC & PP = clean, food-grade, safety

- 🚿 PVC = plumbing and power cables, not for food

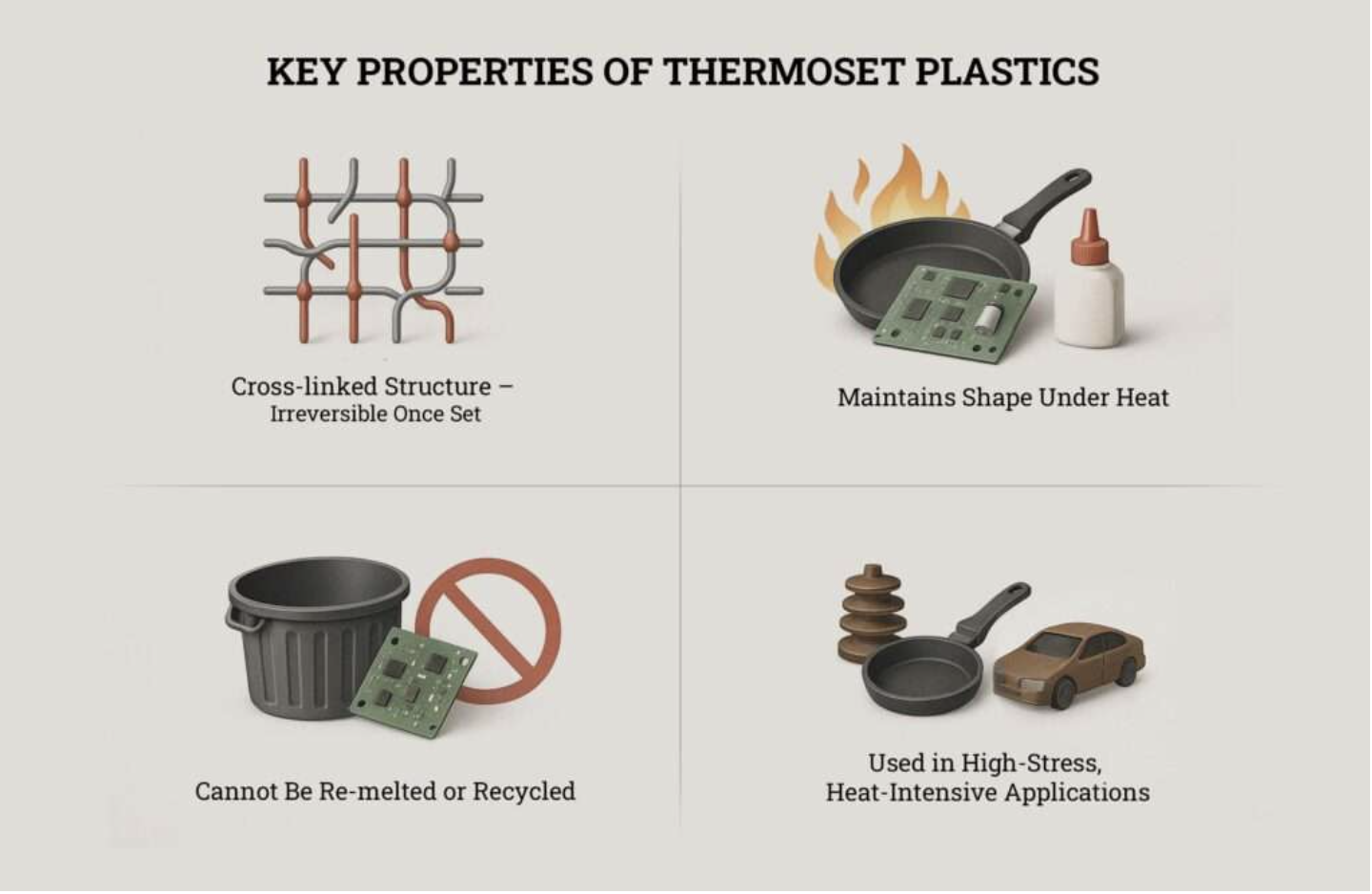

❌ Thermosetting Materials

· Cannot be melted and reshaped once cured.

· They undergo a chemical reaction during molding and become permanently hard.

· Not recyclable by remelting.

· After curing, they’re very heat- and chemical-resistant.

🔧 Can Thermosetting Materials Be Used in Injection Molding?

Yes — but the process is different from standard plastic injection molding. The term is often called:

Thermoset Injection Molding or Compression Molding

In this process:

· The raw material (usually in the form of a powder or semi-solid) is injected into a heated mold.

· The curing reaction happens inside the mold under heat and pressure.

· Once cured, the part is ejected — it cannot be remelted.

🧪 Common Thermosetting Materials Used in Molding:

Here are typical examples used in thermoset molding:

Material | Description | Use Cases |

Phenolic (PF) | Excellent heat resistance, low cost | Electrical components, handles |

Melamine (MF) | Stiff, hard, decorative | Tableware, switches |

Epoxy (EP) | Very strong adhesive, chemical-resistant | Electrical insulators |

Urea-Formaldehyde (UF) | Hard, glossy, low-cost | Light switch housings, adhesives |

Polyester Resin (UP) | Used in SMC/BMC (sheet/bulk molding compound) | Automotive parts, enclosures |

Silicone Rubber (LSR) | Flexible, heat-resistant | Baby products, medical devices |

🏭 Processes to Mold Thermosets:

· Thermoset Injection Molding

· Compression Molding

· Transfer Molding

⚠️ Note: Thermosetting materials often require steel molds with temperature control systems, and longer cycle times due to curing.

⚙️ Why Thermoplastic Molding Is More Precise:

Factor | Thermoplastic Molding | Thermosetting Molding |

Dimensional Precision | ✅ High — due to fast cooling and minimal chemical change | ❌ Lower — due to chemical curing and possible shrinkage variation |

Process Control | ✅ Easier to control temperature, flow, and cooling | ❌ Harder — curing reactions are less predictable |

Repeatability | ✅ Very high | ❌ Lower repeatability |

Surface Finish | ✅ Excellent surface finish possible | ⚠️ Often rougher (especially in compression molding) |

Tool Wear | ⚠️ Can be high, but predictable | ⚠️ Thermosets are abrasive and wear tools faster |

📌 When Thermosetting Molding Is Preferred:

Although less precise, thermoset molding is used when heat resistance, electrical insulation, or mechanical stability at high temperatures are critical. For example:

· Circuit breaker housings

· Cookware handles

· High-temperature insulators

Thermosetting plastics, on the other hand, undergo a chemical reaction when cured — meaning once they are molded and set, they cannot be melted or reshaped again. Materials like epoxy, phenolic, and silicone rubber (such as LSR) fall into this category. The reason they can’t be recycled like thermoplastics is that the cross-linked molecular structure formed during curing is permanent. For example, in LSR molding, two liquid components react chemically in a heated mold to form a solid, heat-resistant product. Once set, these materials offer superior thermal stability and chemical resistance, making them ideal for high-performance applications — but at the cost of recyclability and sometimes surface precision.

Silicone parts (especially liquid silicone rubber, or LSR) are typically made using a thermosetting molding process, most commonly:

🔹 Compression Molding

This is very common for solid silicone rubber. Preheated silicone is placed into a mold cavity, then compressed and cured with heat.

🔹 Liquid Injection Molding (LIM/LSR)

For liquid silicone rubber (LSR), this process involves injecting two liquid components into a heated mold, where they chemically cure (not melt).

✅ Why it's thermoset:

Silicone undergoes a chemical curing process during molding — once it's cured, it cannot be melted and reshaped. That's the definition of a thermosetting polymer.

🌡️ Why Thermosetting Materials Can't Be Recycled

Yes — the main reason is the chemical reaction that happens during molding.

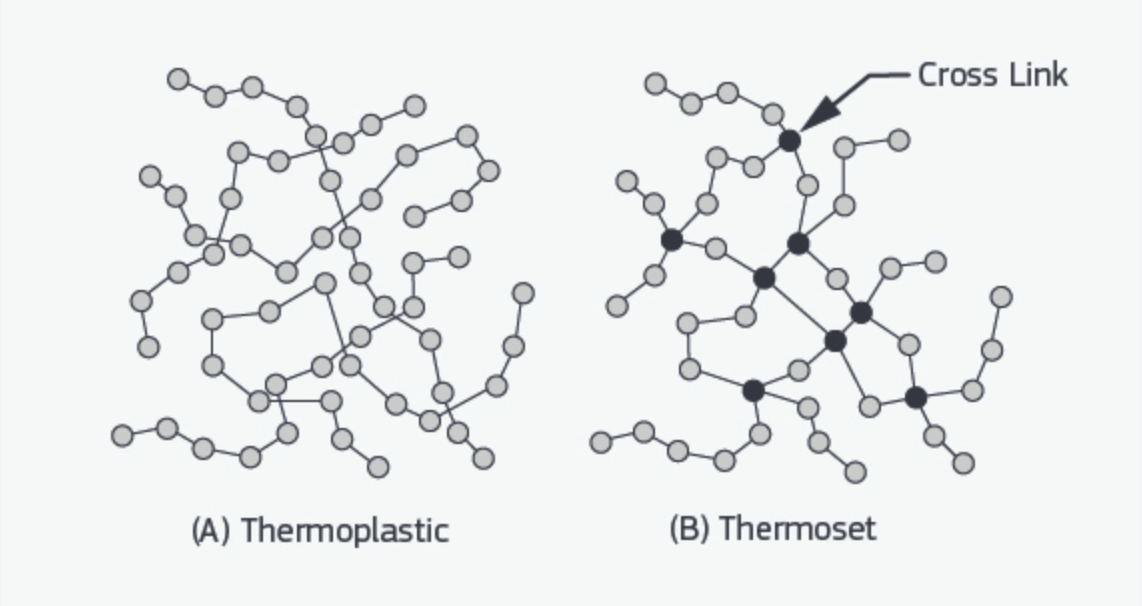

🔬 1. Chemical crosslinking

When thermoset materials (like LSR or epoxy) are heated and cured, they undergo a chemical reaction called "crosslinking". This links the polymer chains together into a solid, three-dimensional network.

· Once crosslinked = permanently hardened

· Cannot melt again

· Cannot reshape

· Cannot be reprocessed like thermoplastics

💡 Think of boiled eggs:

You can’t turn a boiled egg back into a raw one — the proteins have undergone an irreversible change. Thermosets are similar.

🧪 2. Example: LSR

Liquid Silicone Rubber has two parts (A + B) — when mixed and heated in the mold, they react and cure irreversibly.

· After curing, it becomes rubbery and flexible

· But it cannot be melted again, no matter how much you heat it

🧱 3. What about hard thermosets like Bakelite, epoxy, etc.?

Even though they start as solid or powder form, the same principle applies:

· When heated and compressed in a mold, they go through a chemical change

· This changes their structure permanently

· After that, you can’t melt them again or re-form them

In summary, thermoplastics are valued for their flexibility, reusability, and wide range of properties, while thermosets are chosen for their durability and resistance to heat and chemicals. Understanding the difference is crucial for selecting the right material for any manufacturing project — whether it's a food container, automotive part, or high-precision silicone seal.

As industries move toward more sustainable solutions, knowing how and why each material behaves the way it does helps in making smarter design and production decisions.

Factory add: No 39, Zhen an west road, Changan town , Dong guan city, China.