Understanding Key Parameters and Phases in Injection Molding: A Practical Guide

Injection molding is one of the most widely used manufacturing processes in the plastics industry. Whether you’re a process engineer, project manager, or business developer in the field, understanding the basic principles and keywords in injection molding will help you communicate more effectively with both your customers and technical teams.

This article will walk you through the four key phases of injection molding, as well as explain essential parameters such as tonnage, mold temperature, and the roles of hot oil or chill water.

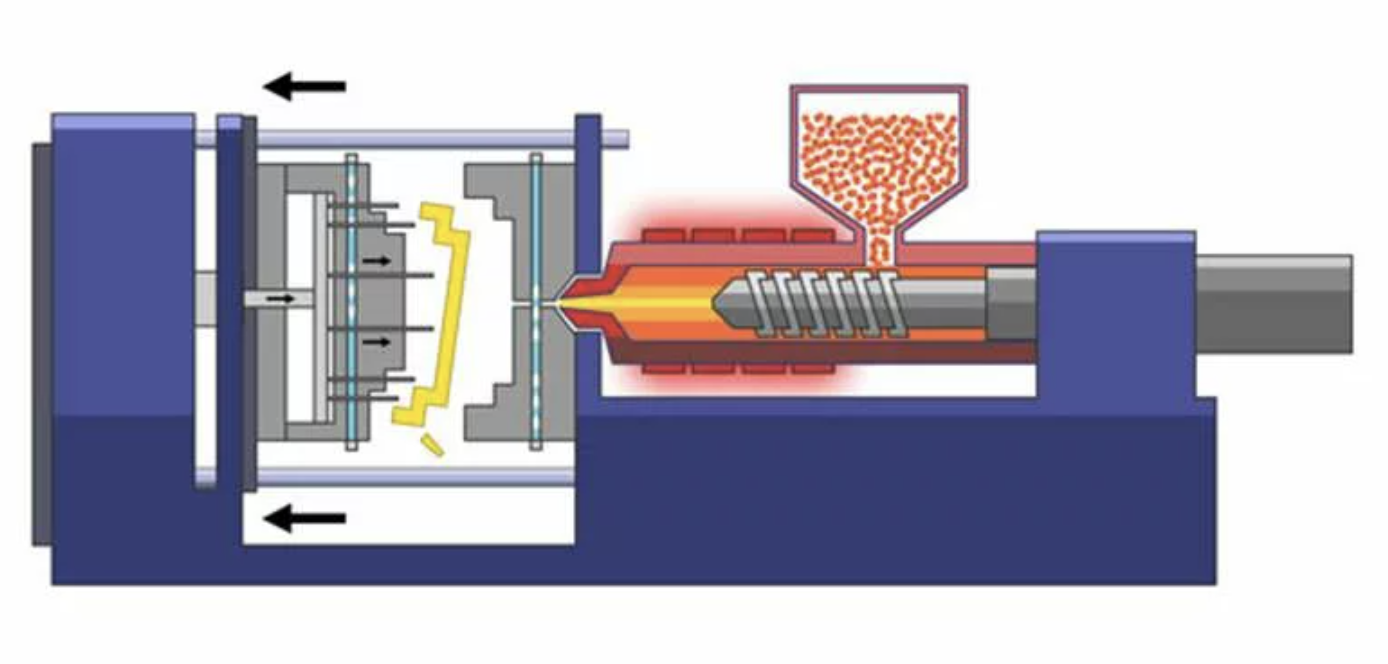

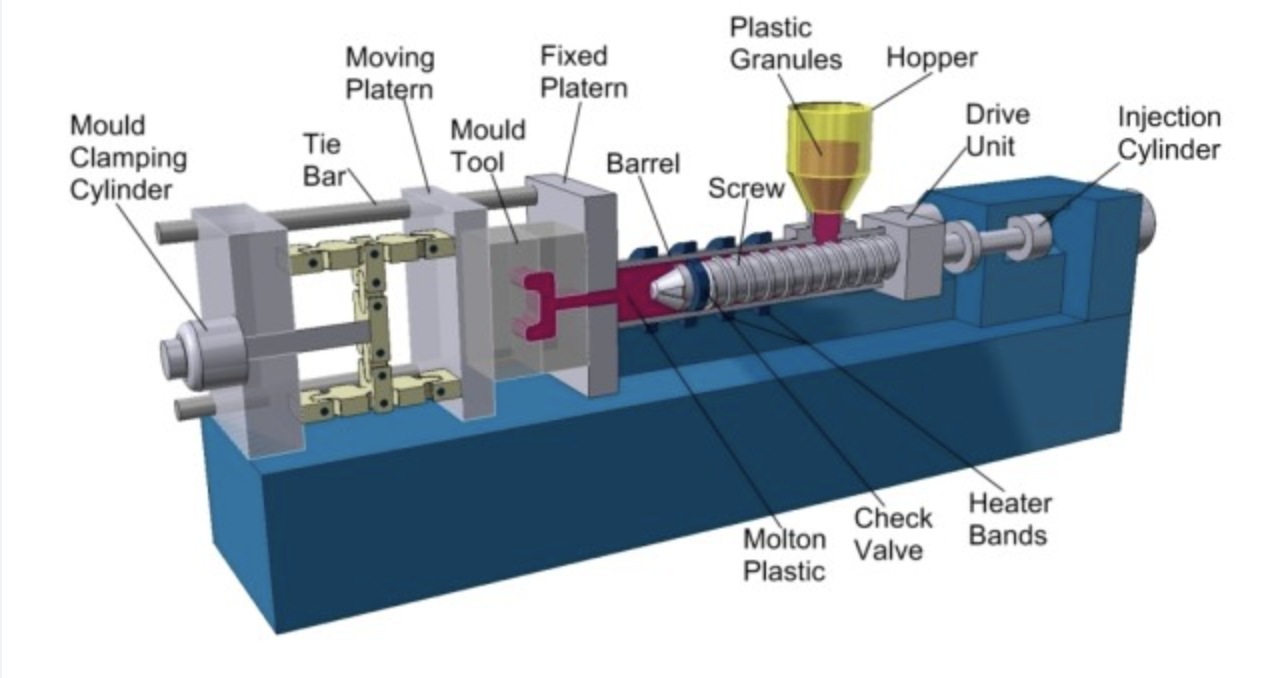

Tonnage: The Clamping Force of the Injection Molding Machine

- Tonnage refers to the clamping force that the injection molding machine applies to keep the mold closed during injection.

- It’s measured in tons (e.g. 80T, 120T, 350T).

- Why it matters: when plastic is injected into the mold at high pressure, it tries to force the mold open — so the clamping unit needs enough tonnage to hold the mold tightly shut.

- A basic formula used in estimation:

Required Tonnage (tons) ≈ Projected Area (cm²) × Injection Pressure (kg/cm²) ÷ 1000

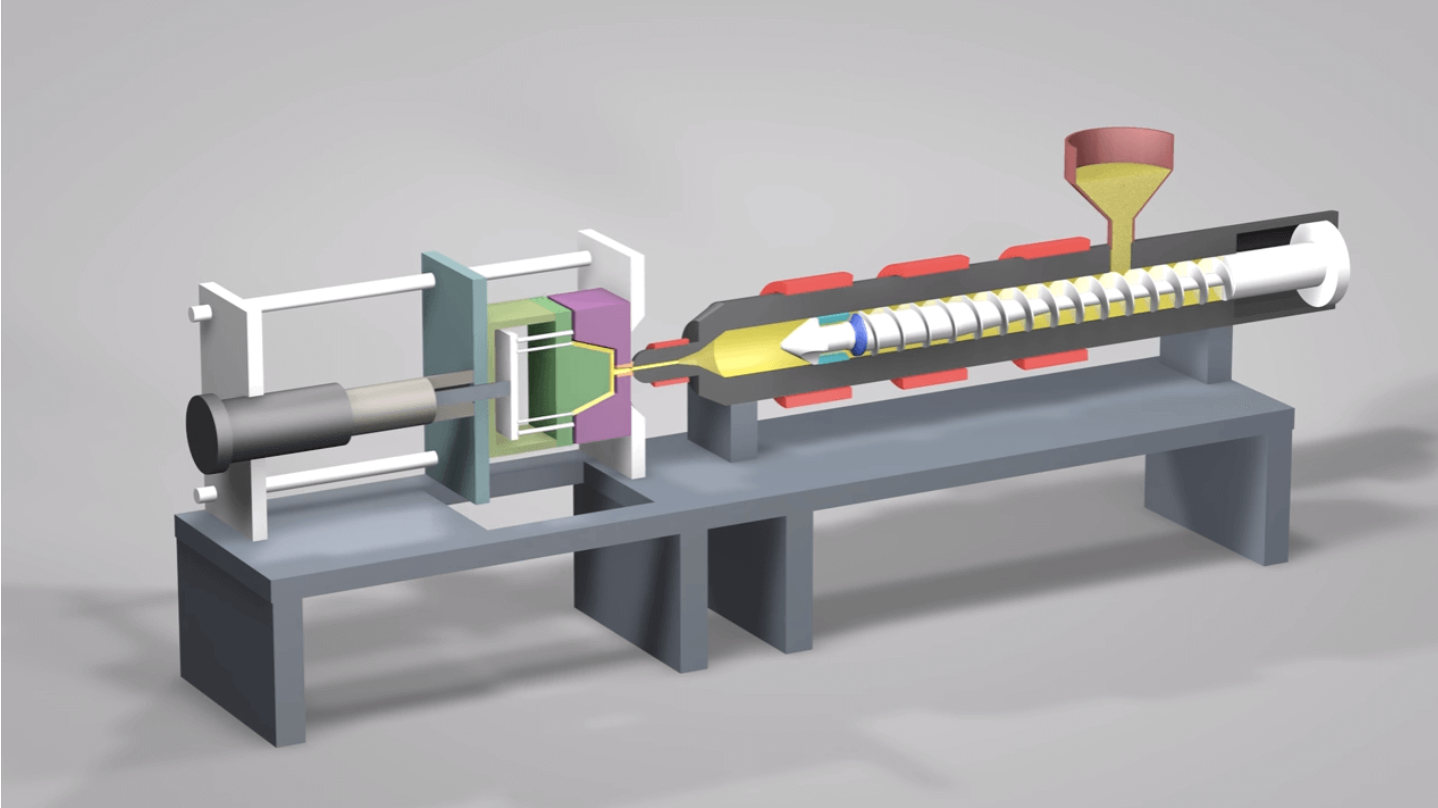

The 4 Phases of Injection Molding

Injection molding typically consists of four major phases:

A. Injection Phase:

In this first phase, melted plastic is injected into the mold cavity. Key terms include:

- Injection Pressure: The pressure needed to push molten plastic into the mold.

- Injection Speed: The speed at which the plastic is injected; it affects filling quality and precision.

B. Packing (or Holding) Phase:

After the cavity is filled, holding pressure is applied to pack more material into the cavity, ensuring dimensional accuracy and avoiding shrinkage or sink marks.

- Holding Pressure: Maintains pressure after injection to compensate for shrinkage.

- Holding Time: Duration of the holding pressure.

C. Cooling Phase:

Once the cavity is filled and packed, the plastic cools and solidifies. During this stage:

- Clamping Force (or Tonnage): The force needed to keep the mold tightly closed during injection and cooling. It depends on part size and material flow pressure.

- Mold temperature and cooling water (or oil) are vital here — more on that below.

D. Mold Opening & Ejection Phase:

Once cooled, the mold opens and the part is ejected. At this stage:

- Ejection Stroke and Ejection Speed control how smoothly and quickly the finished product is released.

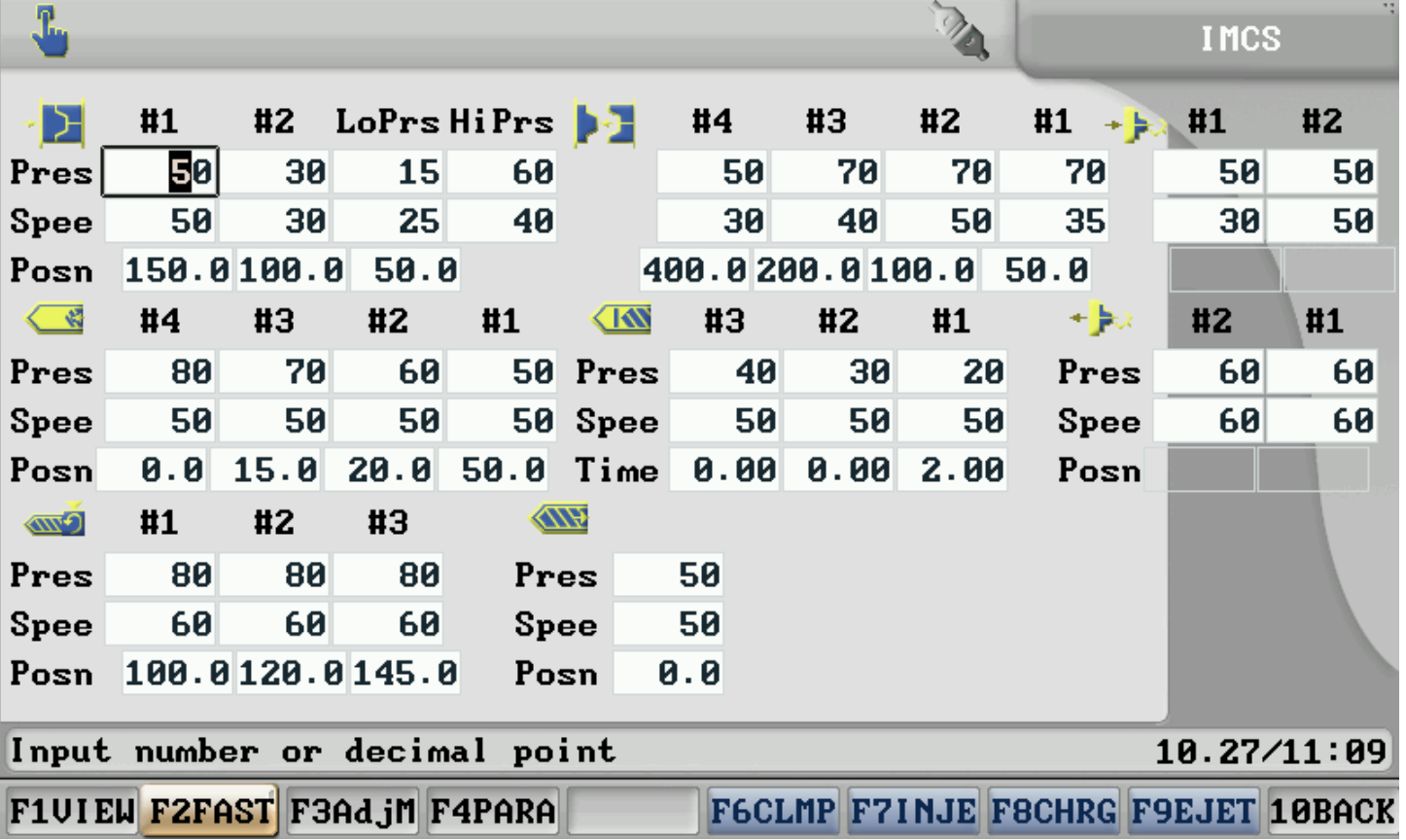

🔹 A, B, C, D = Multi-Stage Injection Settings

These stages usually refer to a multi-stage injection process, especially in precision molding where multi-speed / multi-pressure control is required. Here's how it works:

✅ A Phase (1st Stage Injection)

- High speed to fill most of the mold quickly.

- Settable Parameters:

- Injection speed (mm/s or %)

- Switching position (mm) — when to move to B phase.

- Pressure (bar) if controlled separately.

✅ B Phase (2nd Stage Injection)

- Reduced speed to prevent overpacking, especially near the end of the fill.

- Settable Parameters:

- Speed

- Switching position (end of fill or start of holding)

- Pressure

✅ C Phase (Holding / Packing)

- Applies pressure to compensate for material shrinkage as it cools.

- Settable Parameters:

- Holding pressure (bar)

- Holding time (s) — usually a few seconds

- Number of stages — e.g. stepwise reduction

✅ D Phase (Cooling)

- The plastic cools and solidifies under clamping force.

- Settable Parameters:

- Cooling time (s)

- Not much speed/pressure setting, but affects cycle time

💡 Why Use Multiple Phases?

Because:

- Early stage: you want speed for filling

- End of filling: slower to avoid flashing

- Holding: enough pressure to avoid sink marks

- Cooling: proper time ensures part dimension stability

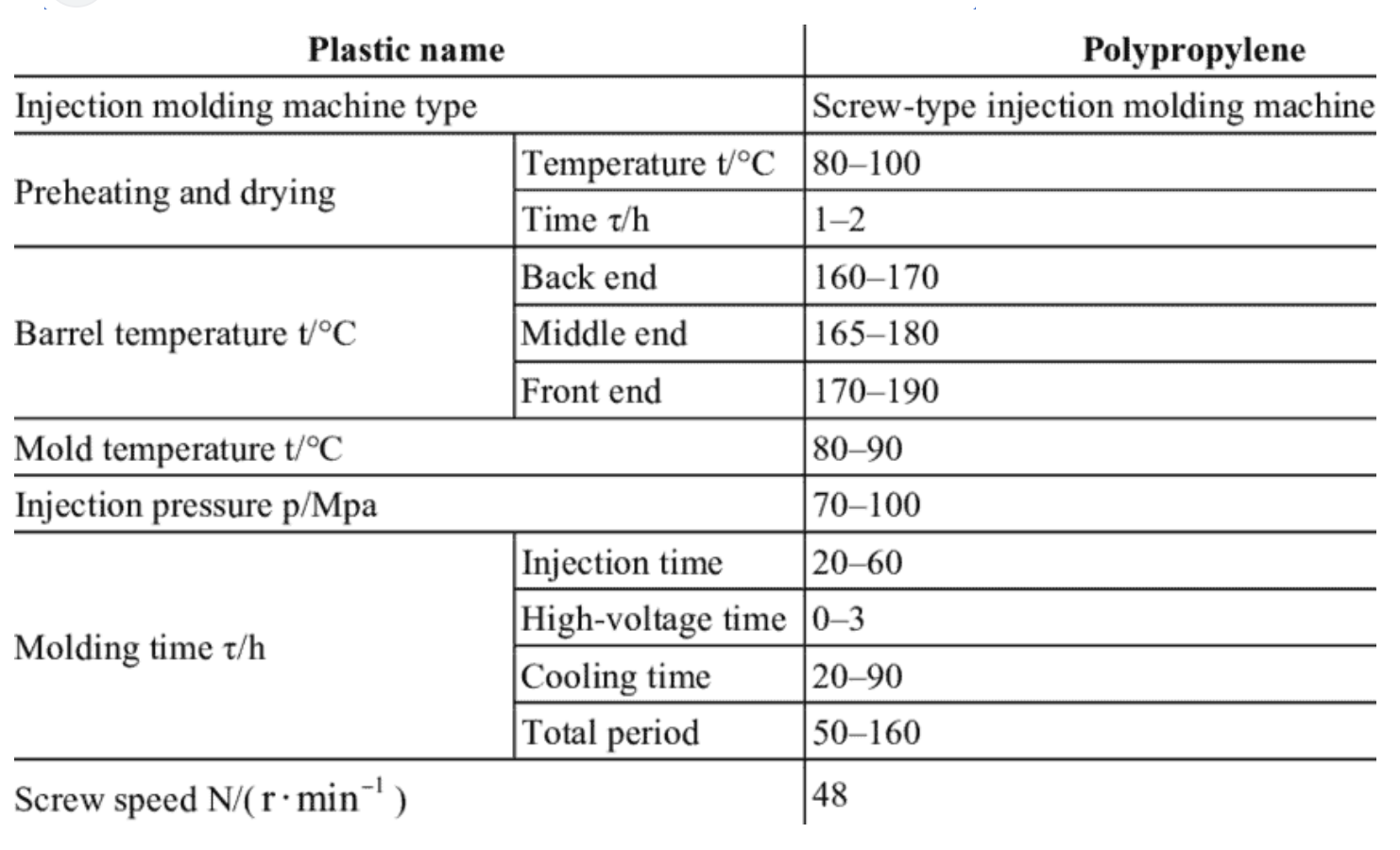

Important Injection Molding Parameters & Why They Matter

Here are some commonly used technical terms and what they mean:

- Tonnage / Clamping Force: The force needed to keep the mold closed during injection. It must be greater than the injection pressure to avoid mold separation or flashing.

- Mold Temperature Setting: Affects part surface quality, dimensional stability, and cycle time. Each material (like ABS, PC, or Nylon) requires a different mold temperature to optimize flow and minimize defects.

- Chilled Water / Hot Water / Hot Oil: These are used to control mold temperature.

- Chilled Water helps quickly solidify parts and shorten cycle time.

- Hot Water or Hot Oil is used for materials requiring higher mold temperatures or uniform heat distribution (especially semi-crystalline plastics or complex geometries).

- Returning Charge (回料): Also known as plasticizing or recharging, this is the process where the screw rotates to bring in new material for the next cycle.

- Shot Return Position (倒索位置): This refers to the position the screw returns to after injecting material — preparing for the next cycle.

🔄 A Simplified Cycle with These Terms:

1. Mold closes → Clamping force applied

2. Injection starts → A & B Phases

3. Hold pressure applied → C Phase

4. Cooling time begins → Screw rotates = 回料 (returning charge)

5. Screw stops at 倒索位置 = ready for next shot

6. Mold opens → Eject the part

7. Repeat

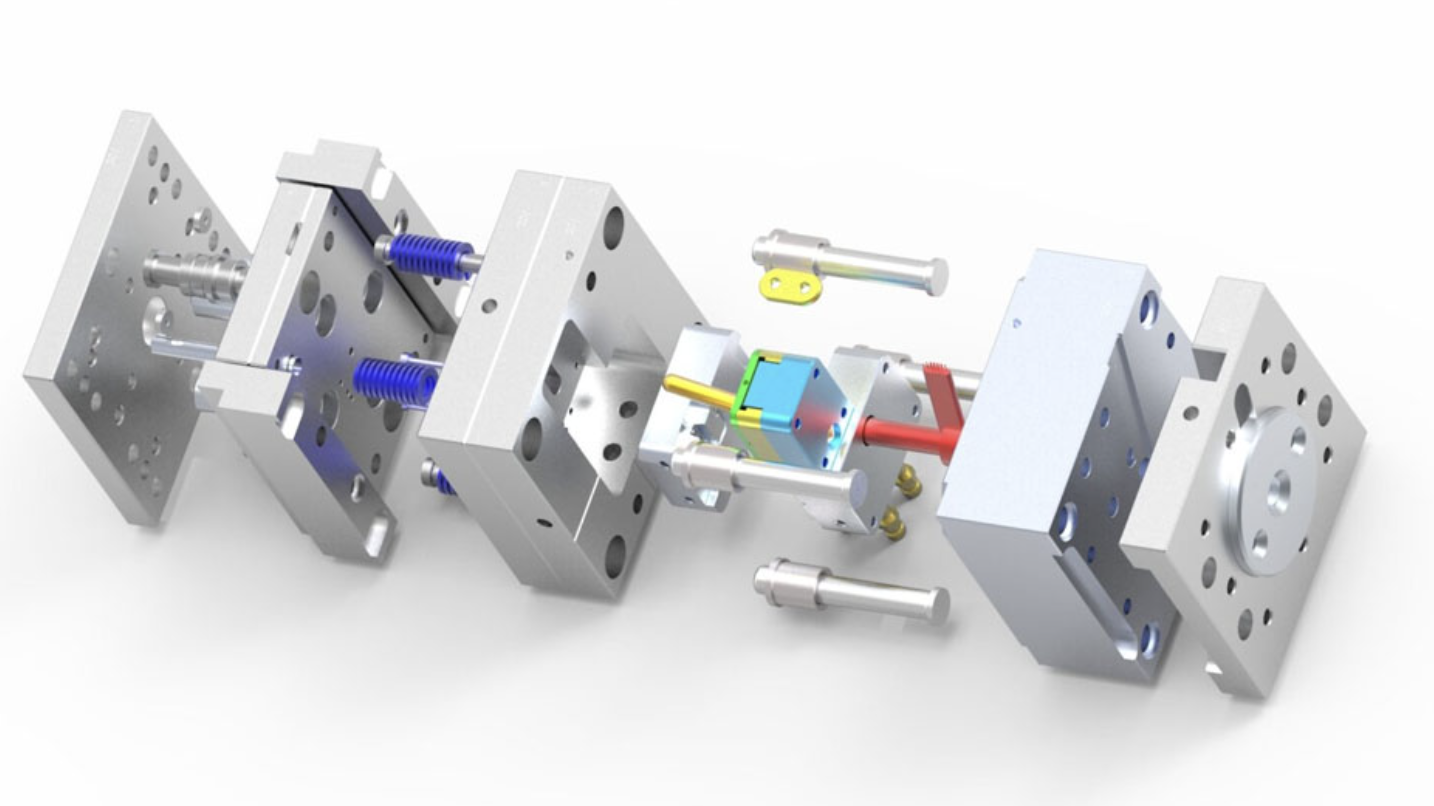

🧊🔥 What is Mold Temperature Setting?

✅ Mold temperature refers to:

The temperature of the mold plates and inserts during injection molding. It’s controlled by circulating coolant through channels inside the mold.

🔧 Why Does Mold Temperature Matter?

Reason | Explanation |

🌡️ Flowability of plastic | Higher mold temps help some plastics flow better into small or thin areas. |

📏 Shrinkage & warpage | Mold temp affects how the part cools, impacting dimensional accuracy. |

✨ Surface finish | Too cold = dull surface / flow marks. Proper temp = smooth finish. |

⏱️ Cycle time | Higher temp = slower cooling, longer cycle. But too low = defects. So it's a balance. |

💧 Types of Temperature Control Fluids (You saw these terms):

Term | Used for | Typical Temp Range | Explanation |

Chilled water (冷水) | Cooling the mold | ~5–25°C | Used when mold needs fast cooling, for semi-crystalline plastics like PP, POM, etc. |

Machine water (常温水) | General cooling | ~25–35°C | Regular tap water, for general-purpose cooling. Often used when tight control isn't needed. |

Hot water (热水) | Heating mold | ~40–90°C | Helps when the material needs a warmer mold to flow well or avoid defects. |

Hot oil (导热油) | High-temp molds | ~100–200°C | Used when hot water is not enough (e.g. PC, PMMA, PA) — oil circulates through the mold via a thermal unit. |

🧪 Do You Use Water or Oil Every Time?

✅ Yes, every time, but the type depends on:

Understanding these key phases and terminology in injection molding is essential for optimizing production quality, improving communication, and supporting customers more professionally. Whether you are selecting the correct tonnage, adjusting holding pressure, or understanding why a mold needs chilled water or hot oil, these parameters directly impact the performance, efficiency, and cost of your molding process.

As sales engineers or business developers in manufacturing, knowing these concepts helps bridge the gap between client expectations and production realities — making every project smoother and more successful.