Understanding Investment Casting: What It Is, How It Works, and Why Wax Matters

By Danny

Business Development Manager, [Opro tech engineering]

Introduction: "Why Can Wax Be Used to Make Steel Parts?"

That’s exactly the question I asked myself the first time I heard about investment casting.

I’ve worked with many manufacturing processes like CNC machining, vacuum casting, and die casting. But when a client recently asked whether it was possible to make a wax injection mold for an impeller without using soluble wax, I had to pause and think:

“Wait… wax? Steel? How does this all work?”

So I took a deep dive — and now I want to share everything I learned with you in plain, clear language.

What Is Investment Casting?

Investment casting, also known as precision casting or lost wax casting, is a process used to create highly accurate and complex metal parts — especially in materials like stainless steel, aluminum, titanium, or cobalt-chrome.

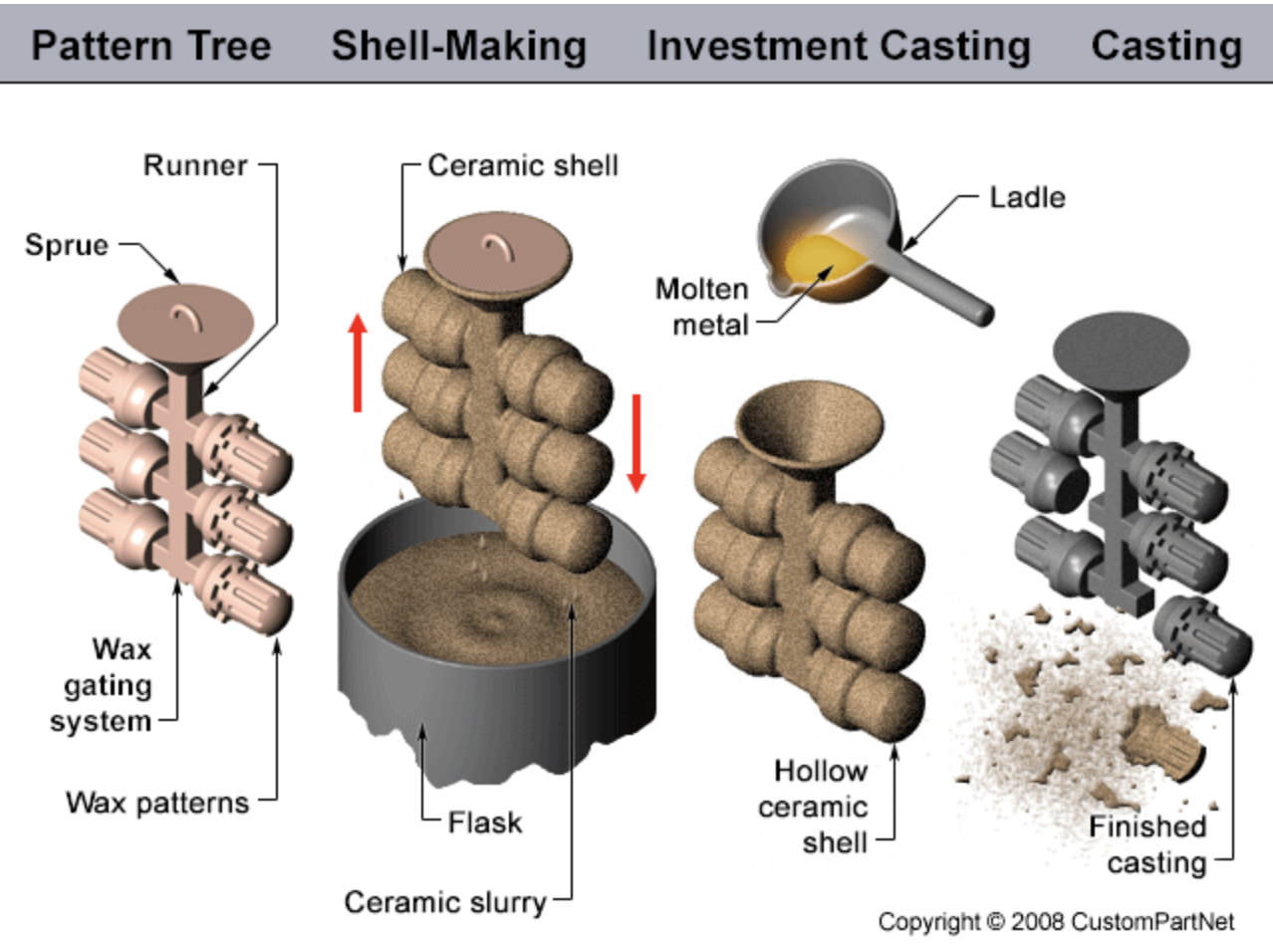

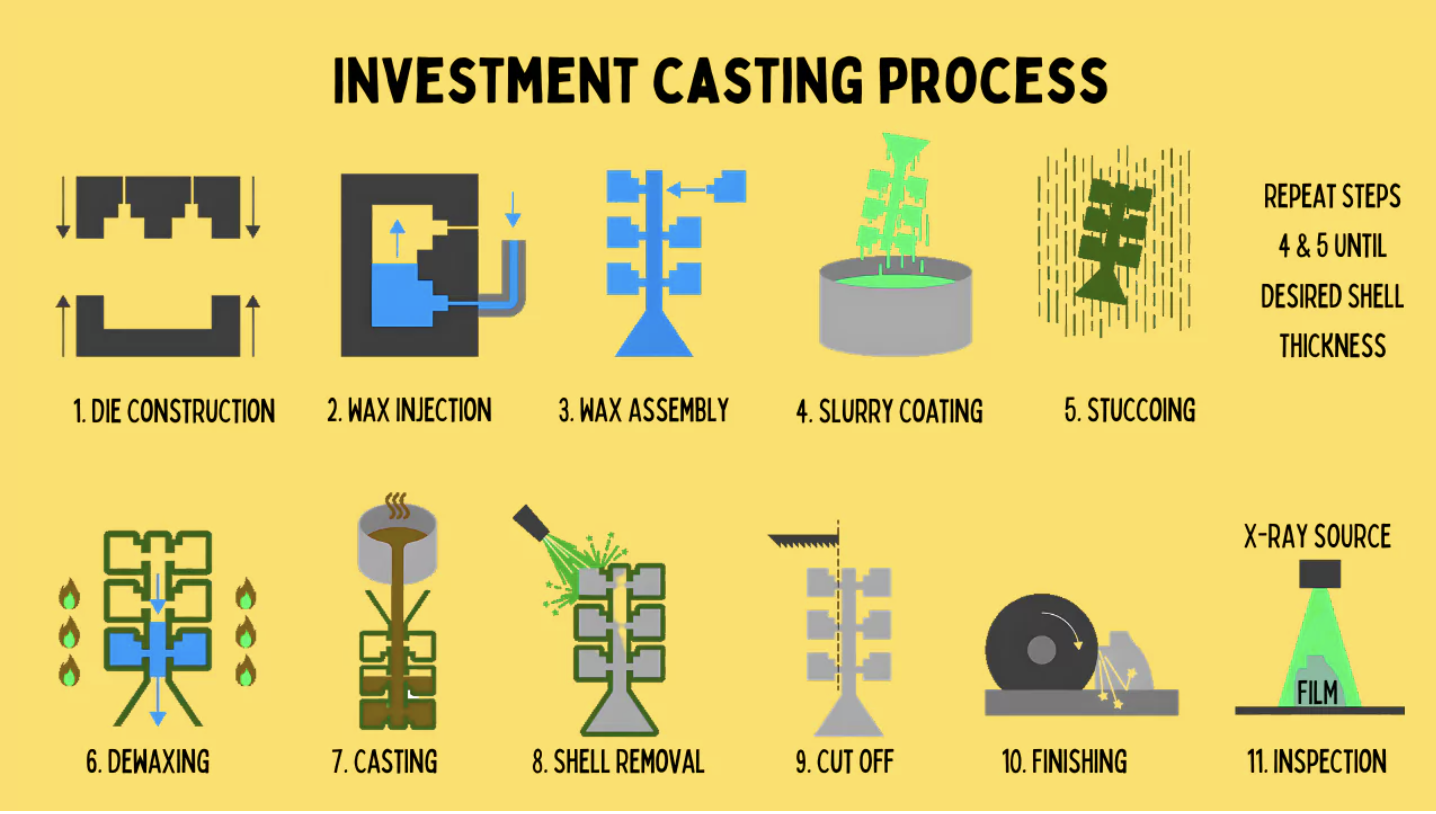

It works like this:

- You first make a wax model of the part (this is your temporary “copy”).

- The wax model is repeatedly dipped in ceramic slurry to form a ceramic shell around it.

- Once the shell is dry and hard, it’s heated — the wax inside melts and flows out. (That’s the “lost wax” part.)

- Molten metal is poured into the empty ceramic shell.

- After cooling, the ceramic shell is broken, and the metal part is revealed.

🔁 The wax model is destroyed in every cycle, but the metal mold that creates the wax model can be reused.

Why Is It Called “Investment” Casting?

Great question — and one that confused me at first too!

The word “investment” doesn’t mean money or finance here. It comes from the Latin investire, meaning to clothe, to cover.

In this context, investment refers to the act of coating or encasing the wax model with ceramic slurry. You’re “investing” the model in layers of ceramic — and that’s how the process got its name.

Pretty cool, right?

What Is a Wax Mold? And What Is Soluble Wax?

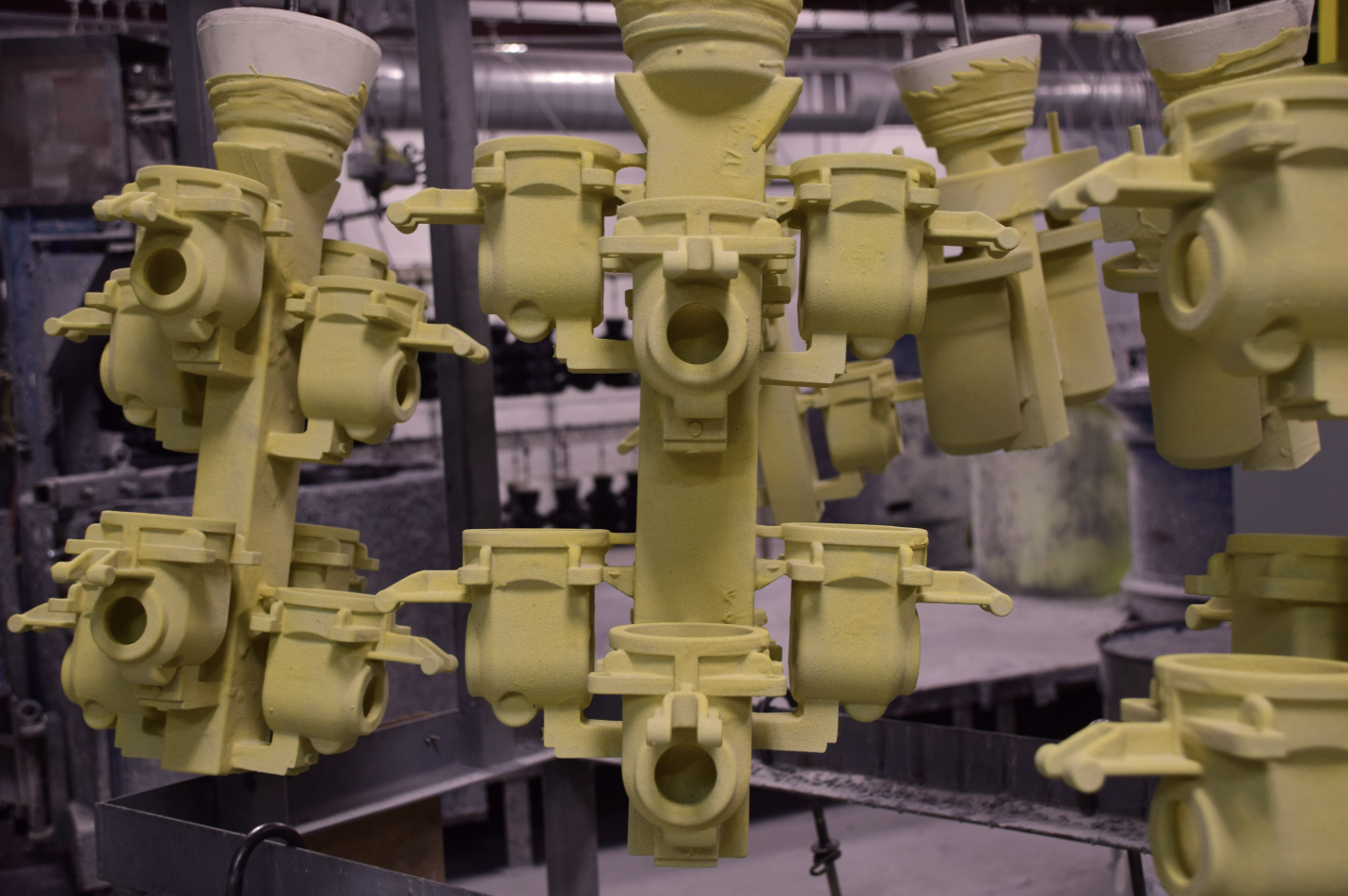

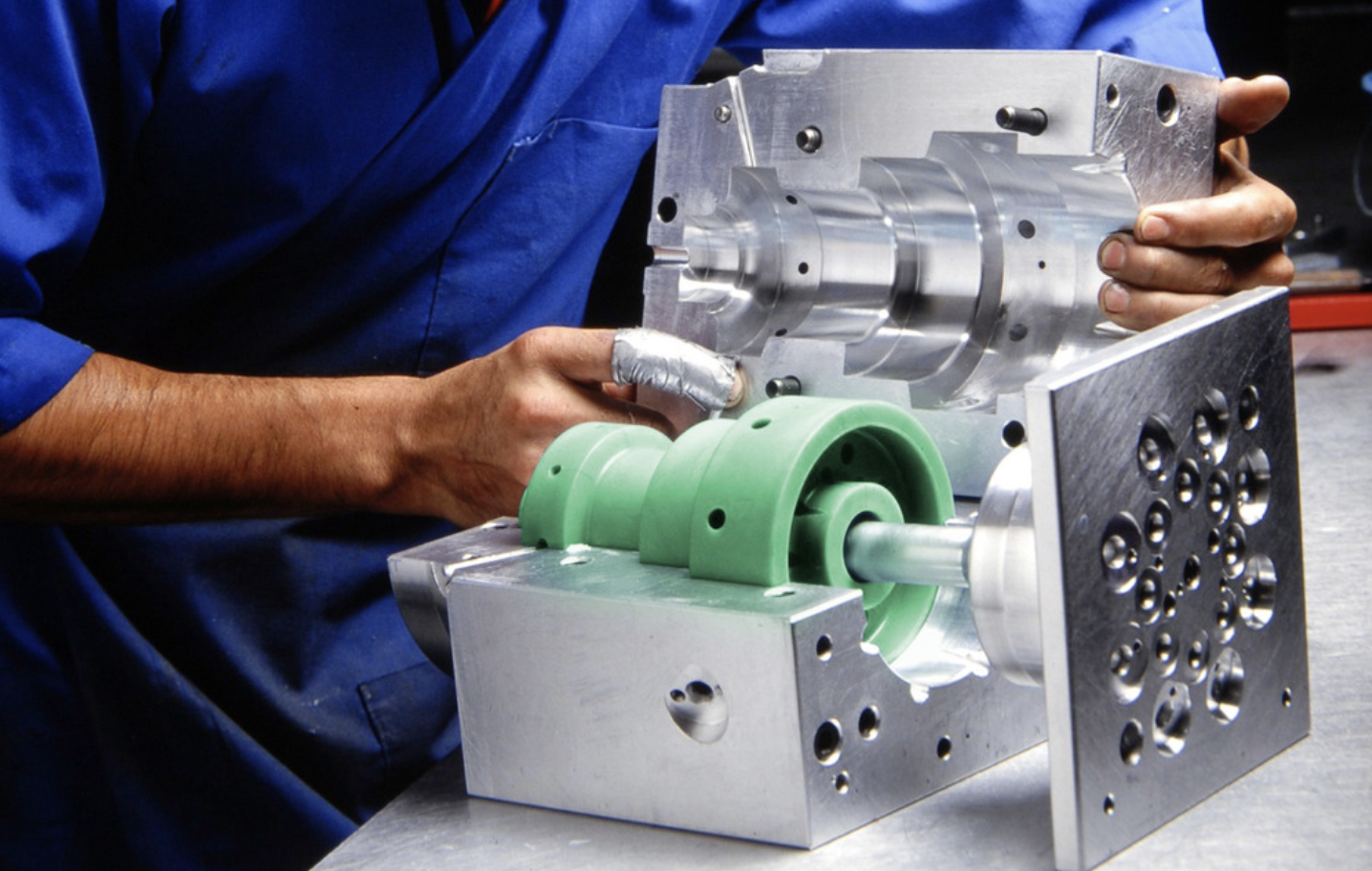

In investment casting, we use wax injection molds to produce wax replicas of the final product.

There are two main types of wax:

Type | Description | Use Case |

Hard Wax (Standard Wax) | Regular wax used for most of the part shape. Can be easily injected and handled. | For outer profiles and simpler parts. |

Soluble Wax | Special wax that can dissolve in water or solvent. Used to form internal passages. | For complex parts with internal cavities, like impellers, valves, or turbine blades. |

Why Is Soluble Wax Sometimes Necessary?

This was my question to a tooling engineer:

“Can't we just use regular wax for everything?”

The answer is: not always.

Here’s why:

When your part has internal features (like channels, hollow spaces, or overhangs), it's almost impossible to pull the wax core out after injection. This is where soluble wax comes in — it can form those tricky internal geometries and then dissolve away, leaving the outer shell intact.

For example:

An impeller (like the one my client shared with me) has vanes, flow channels, and overlapping profiles. Using only hard wax would make it extremely difficult to demold without breaking the wax part. But with soluble wax, we can build the internal shapes safely.

Is the Ceramic Shell Really That Strong?

Yes — and this part amazed me.

After forming the wax model, we build the ceramic shell by:

- Dipping the wax model in ceramic slurry.

- Sprinkling ceramic sand to strengthen the surface.

- Letting it dry.

- Repeating the process 5–7 times to create a thick, heat-resistant outer shell.

Once the wax is melted out, the ceramic shell can withstand temperatures of over 1600°C, making it strong enough to hold molten stainless steel, aluminum, or titanium.

🧱 But remember: the shell is single-use — it’s broken after casting to release the final metal part.

Why Use Investment Casting Instead of Die Casting or Vacuum Casting?

Here’s a simple comparison to help you see the differences:

Feature | Investment Casting | Die Casting | Vacuum Casting |

Material | Stainless steel, titanium, cobalt-chrome, etc. | Zinc, aluminum, magnesium | Polyurethane resin, silicone |

Tooling | Wax injection mold + ceramic shell (one-time) | Metal die mold (long-term) | Silicone mold |

Part Complexity | Extremely high | Moderate | High (for plastics) |

Surface Finish | Excellent | Good | Good |

Cost | Higher (per piece), good for medium to low volume | Lower (per piece), good for high volume | Low setup cost, great for prototypes |

So if you want complex metal parts with excellent surface finish and tight tolerances, investment casting is a great option — especially for aerospace, medical, pump, and precision mechanical parts.

FAQs — Beginner Questions I Asked (and You Might Too)

Q1: If we use wax, isn’t the mold gone after one part?

→ No — we use a metal mold to create many wax models. The wax models are single-use, but the wax injection mold (tooling) is reusable.

Q2: How can wax be used to make stainless steel parts?

→ It’s only a shape copy. Wax is melted out, leaving a cavity in the ceramic shell. That cavity is then filled with molten metal.

Q3: Why can't we always use hard wax?

→ For complex internal structures, you need soluble wax to avoid damaging the part or being unable to remove internal wax cores.

Q4: Can I reuse the ceramic shell?

→ No, the ceramic shell is destroyed after each use to release the metal part.

Investment casting is a beautiful mix of ancient principles and modern technology. It enables manufacturers to produce extremely precise metal parts that other methods can't achieve — all thanks to wax, ceramic, and careful process control.

If you’re exploring whether your part is suitable for investment casting — with or without soluble wax — feel free to contact us. We’re happy to evaluate your design and help you choose the best approach.

Factory add: No 39, Zhen an west road, Changan town , Dong guan city, China.