Engineering Excellence: Unveiling Futaba's Mold Base Mastery

In the ever-evolving world of manufacturing, precision and reliability are paramount, especially in the tooling mold industry.

While many associate Futaba Corporation with cutting-edge electronic components, people also realize the company's prowess extends to crafting exceptional mold bases. This unexpected foray into the tooling mold sector has sparked curiosity and admiration among industry professionals.

As a business development manager deeply embedded in this field, I find myself compelled to explore what makes Futaba so successful across diverse domains. How does an electronics giant achieve such excellence in mold base manufacturing, and what secrets lie behind their remarkable quality and precision?

Futaba Mold Bases

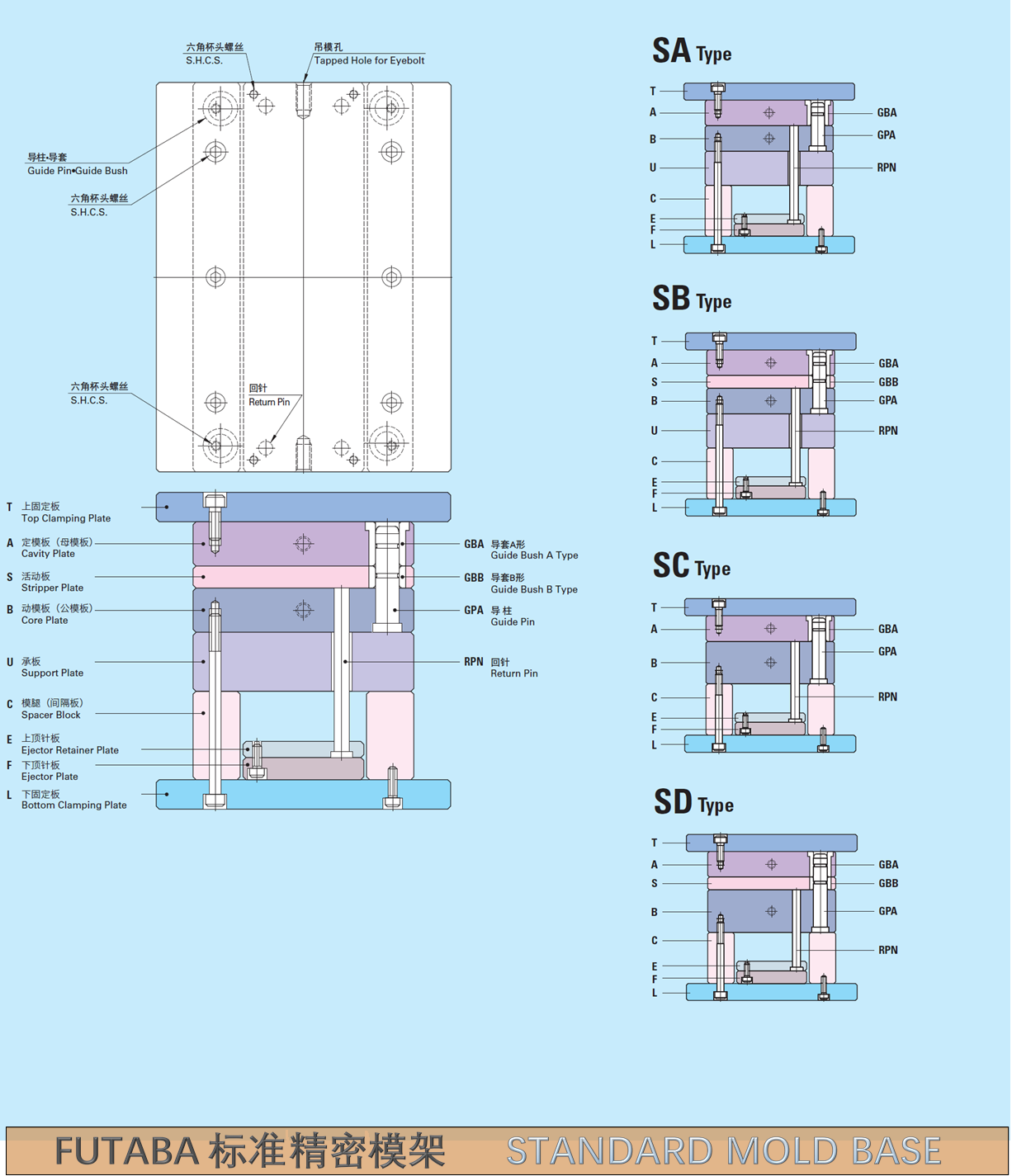

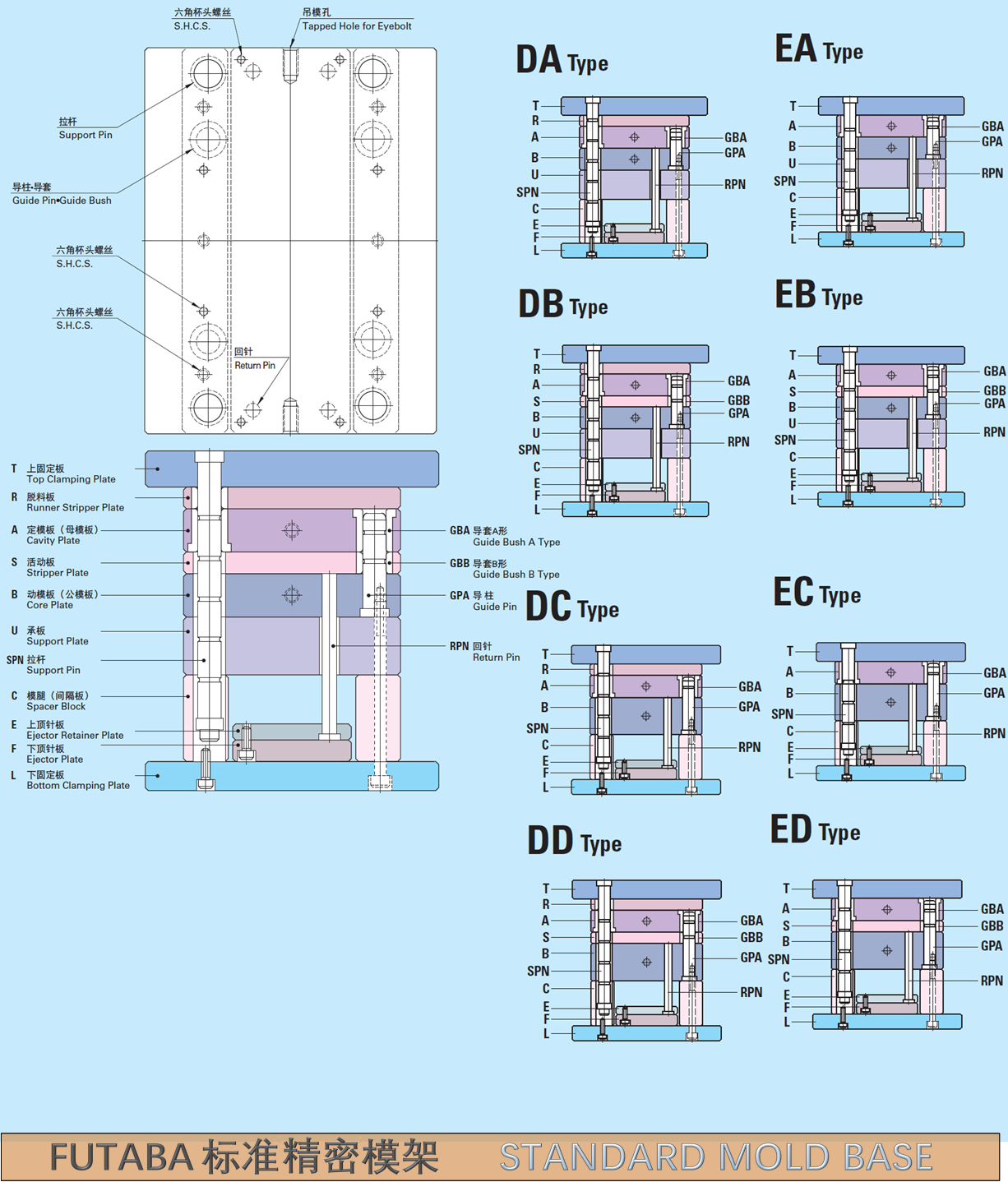

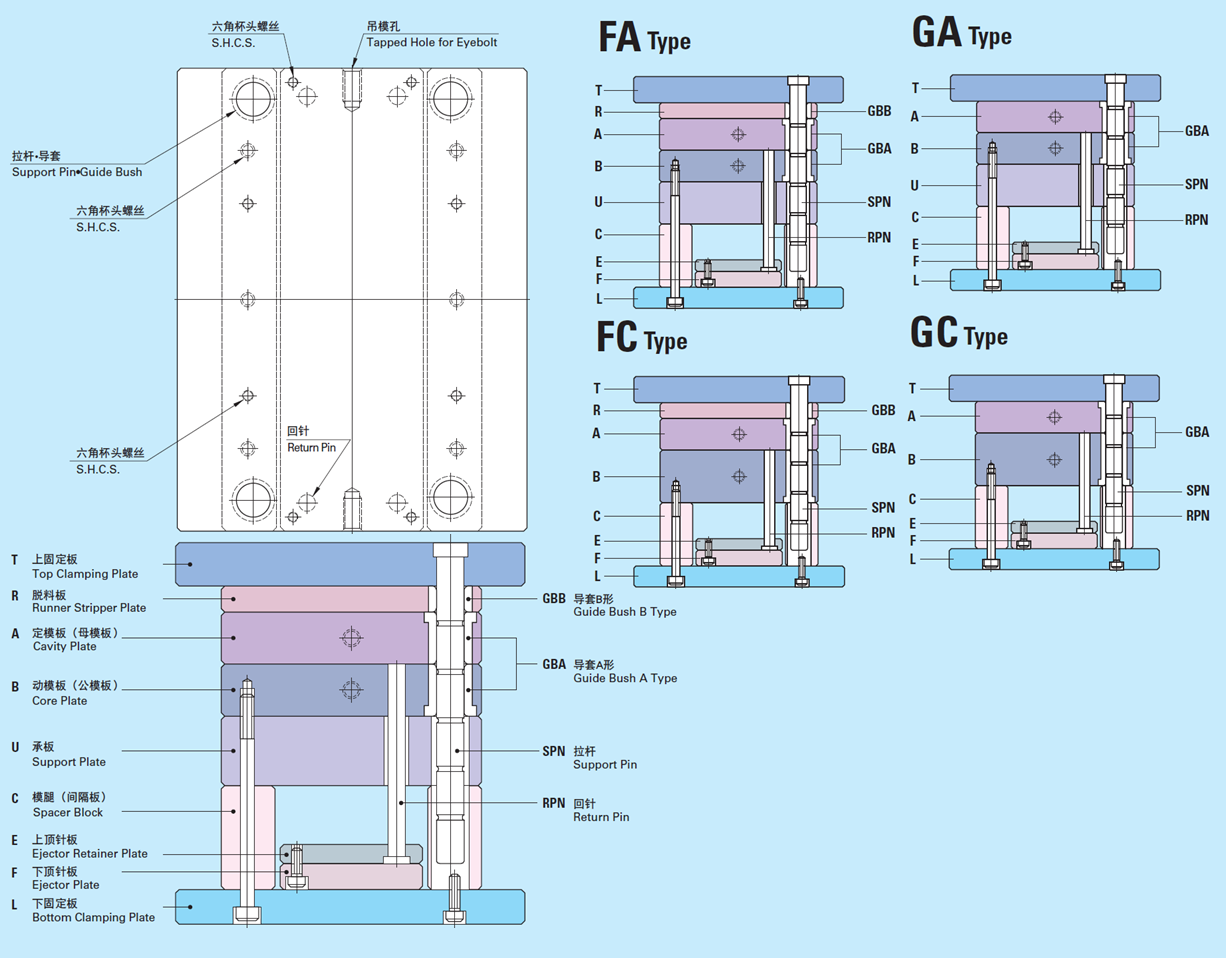

High Precision: Futaba mold bases are manufactured with high precision, ensuring accurate dimensions and tight tolerances, which are critical for high-quality mold making.

Material Quality: They use high-quality steel, often sourced from reputable suppliers, ensuring durability and long service life.

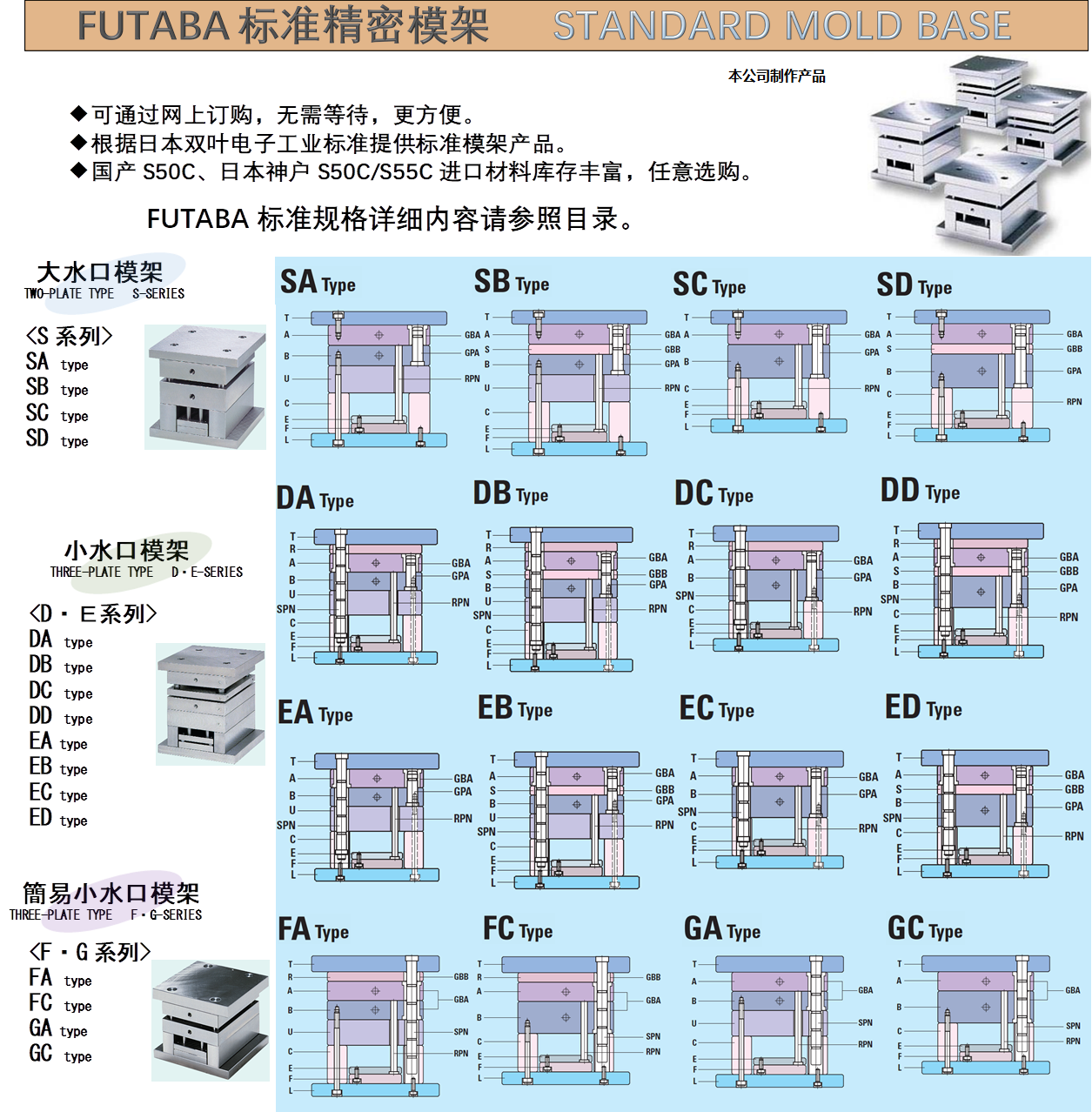

Standardization:

Standardized Components: Futaba offers a range of standardized mold base components, making it easier for mold makers to select and assemble parts quickly.

Global Standards: Their mold bases adhere to international standards, which ensures compatibility and ease of integration into various systems worldwide.

Customization:

Tailored Solutions: While they provide standardized components, Futaba also offers customization to meet specific client requirements. This flexibility is essential for unique and complex mold designs.

Technological Integration:

Advanced Manufacturing: Futaba utilizes advanced manufacturing techniques and machinery, often leveraging their expertise in precision electronics to enhance their mold base production.

Innovation: Continuous innovation in their processes and products helps them stay competitive and meet the evolving needs of the tooling industry.

Why Futaba Excels in Mold Bases

Cross-Industry Expertise:

Precision Engineering: Their background in electronics requires precision engineering, which translates well into mold base manufacturing. The skills and technologies developed for electronic components are applicable to the high-precision needs of mold bases.

Quality Control: Electronics manufacturing demands stringent quality control, a practice that benefits their mold base production.

Reputation and Trust:

Brand Trust: Futaba's established reputation in the electronics industry extends to their mold base division, giving customers confidence in their products.

Global Reach: As a global company, Futaba has extensive distribution networks and customer support, making it easier for clients to access their products and services.

Research and Development:

Continuous Improvement: Their investment in R&D helps them innovate and improve their mold base products, incorporating new materials and manufacturing techniques.

Customer Feedback: Futaba actively seeks and integrates customer feedback, ensuring their products meet industry needs and standards.

Comparison with LKM

LKM (Lung Kee Group): LKM is a leading name in the mold base industry, focusing exclusively on mold bases and related components. They have a wide range of standardized and customized products, known for their reliability and extensive selection.

Focus Difference: While LKM's main business is mold bases, Futaba brings its precision and quality from electronics manufacturing to the mold base industry, offering a unique blend of cross-industry expertise.

In conclusion, Futaba Corporation's success in the tooling mold industry is a testament to their dedication to precision, quality, and innovation.

By leveraging their expertise in electronics manufacturing, Futaba has carved out a unique niche, delivering mold bases that meet the highest standards of the industry.

Their commitment to continuous improvement and customer satisfaction sets them apart, making them a reliable partner for manufacturers worldwide.

As we celebrate and learn from their achievements, it's important to remember that the world of mold base manufacturing is vast and dynamic.

If you have different opinions, experiences, or insights regarding mold bases, we encourage you to share them.

Engaging in this dialogue helps us all learn, grow, and drive the industry forward. Your feedback and stories are invaluable, so please do not hesitate to contribute to this ongoing conversation.

Dan

Business development manager

Phone: +86 134 1699 5669

Skype: danny@opro-tech.com Factory add: No 39, Zhen an west road, Changan town , Dong guan city, China.

Injection Mold / CNC Machining / 3D Printing / Prototyping / Sheet Metal