The Ultimate Guide to Injection Molding Runner Separation: 3 Cutting-Edge Technologies Compared

Introduction: The Critical Final Step

In injection molding, the quality of the finished product isn't just determined within the mold cavity. The final, crucial step—separating the molded part from its runner system—can make or break your product's integrity, aesthetics, and profitability. Choosing the right runner separation technology is no longer just a matter of convenience; it's a strategic decision that impacts your entire manufacturing process.

As products become smaller, more complex, and more precise, traditional methods are being challenged by innovative technologies. In this comprehensive guide, we explore three fundamentally different approaches to runner separation, helping you navigate the complex landscape of post-molding operations.

Method 1: Traditional Die-Cutting (Fixture-Based Cutting)

How It Works

Die-cutting utilizes custom-designed steel fixtures with precisely machined cutting blades. The molded part with runners is placed into the fixture, and hydraulic or pneumatic pressure forces the blades through the runner connections, creating a clean shear separation.

Technical Specifications & Setup

- Tooling Lead Time: 2-6 weeks depending on complexity

- Cutting Force: 1-20 tons typically required

- Tolerance: ±0.1mm to ±0.3mm achievable

- Cycle Time: 0.5-3 seconds per operation

Advantages

✅ Lowest Per-Part Cost at High Volumes – Once amortized, fixture cost becomes negligible

✅ Extremely Fast Cycle Times – Ideal for mass production environments

✅ Proven Reliability – Decades of industry validation and expertise available

✅ Minimal Training Required – Straightforward mechanical operation

✅ Excellent for Thick Runners – Handles heavy cross-sections effectively

Limitations & Challenges

⚠️ High Initial Tooling Investment – $1,000-$10,000 per fixture

⚠️ Zero Flexibility – Each product variation requires new tooling

⚠️ Mechanical Stress Risk – Can cause micro-cracks in delicate parts

⚠️ Maintenance Intensive – Blades require regular sharpening/replacement

⚠️ Storage & Logistics – Physical fixtures require space and management

Ideal Application Profile

- Volume: 100,000+ units annually per part number

- Product Lifecycle: Stable design for 2+ years

- Part Value: Low to medium cost components

- Runner Size: Medium to large cross-sections

- Industry Examples: Consumer packaging, automotive interiors, household goods

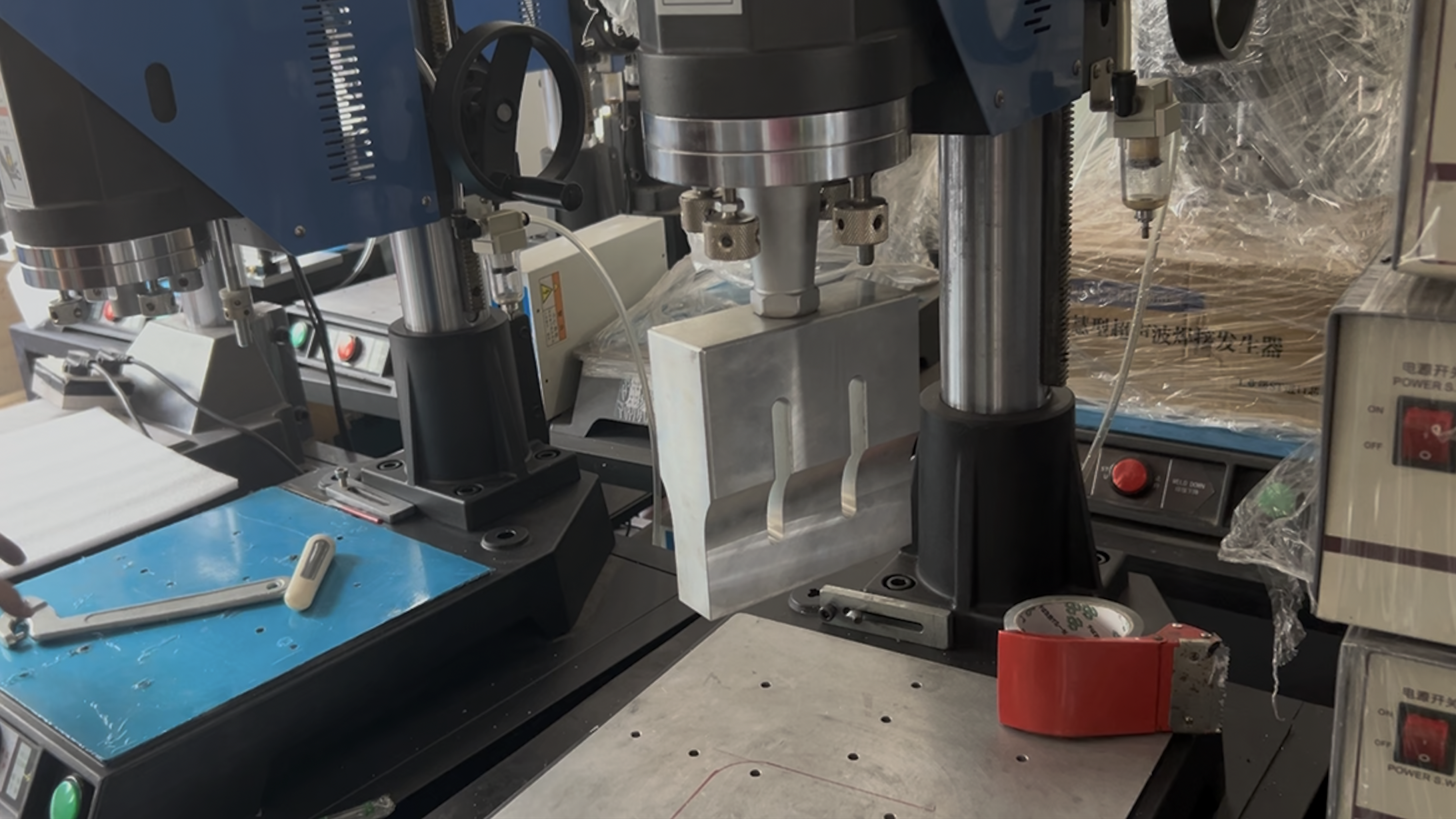

Method 2: Ultrasonic Cutting/Welding Technology

How It Works

This method employs high-frequency (15-40 kHz) ultrasonic vibrations transmitted through a titanium horn (sonotrode) to the runner connection point. The localized friction generates heat at the molecular level, melting the plastic precisely at the separation point.

Technical Specifications & Setup

- Frequency Range: 15 kHz, 20 kHz, 30 kHz, or 40 kHz systems

- Amplitude: 10-100 microns of mechanical vibration

- Cycle Time: 0.2-1.5 seconds typically

- Force Applied: 10-200 Newtons (much lower than die-cutting)

Advantages

✅ Superior Cut Quality – Sealed, smooth edges that resist contamination

✅ Dual Functionality – Can weld and cut in same operation

✅ Reduced Stress – Lower mechanical force than die-cutting

✅ Good for Delicate Parts – Minimizes deformation risk

✅ Relatively Quick Changeover – Different horns can be swapped in 15-30 minutes

Limitations & Challenges

⚠️ Still Requires Custom Tooling – Each product needs a dedicated horn ($500-$3,000)

⚠️ Parameter Sensitivity – Requires precise tuning for each material

⚠️ Skill-Dependent Results – Operator experience significantly impacts quality

⚠️ Noise Generation – High-frequency operation requires hearing protection

⚠️ Limited to Thermoplastics – Not suitable for thermosets or certain composites

Ideal Application Profile

- Volume: 10,000-500,000 units annually

- Part Requirements: Medical devices, labware, food-contact items needing sealed edges

- Material Compatibility: Most thermoplastics (ABS, PC, PP, etc.)

- Secondary Operations: When welding is also required

- Industry Examples: Medical disposables, diagnostic equipment, microfluidic devices

Method 3: Laser Runner Separation Technology

How It Works

The most advanced approach utilizes precisely focused laser beams (typically fiber lasers at 1,070nm wavelength) to deliver concentrated thermal energy to the runner connection. The plastic is either vaporized or melted through without any physical contact.

Technical Specifications & Setup

- Laser Types: Fiber, CO₂, or green lasers depending on material

- Positioning Accuracy: ±0.01mm with galvanometer scanners

- Spot Size: 0.01-0.5mm diameter

- Power Range: 10-500 Watts typically

- Integration: Often includes vision systems and robotics

Advantages

✅ True Non-Contact Process – Zero mechanical stress on parts

✅ Unmatched Precision – Ideal for micro-molded components

✅ Instantaneous Digital Changeover – New product in seconds via software

✅ Exceptional Flexibility – Handles complex geometries effortlessly

✅ Minimal Maintenance – No consumable blades or wearing parts

✅ Smart Manufacturing Ready – Full data tracking and IoT connectivity

✅ Space Efficient – No physical tool storage required

Limitations & Challenges

⚠️ Highest Capital Investment – $50,000-$300,000+ for complete systems

⚠️ Material Restrictions – Challenges with transparent, reflective, or certain colored plastics

⚠️ Energy Consumption – Significant electrical demand

⚠️ Safety Requirements – Class 1 laser enclosure mandatory

⚠️ Technical Expertise Required – Programming and maintenance need specialized skills

Ideal Application Profile

- Volume: Highly flexible—from prototypes to high mix/low volume

- Part Requirements: High-value, precision components

- Product Complexity: Micro-features, fragile designs, tight tolerances (<0.05mm)

- Industry 4.0 Integration: Smart factories with digital workflows

- Industry Examples: Optical components, micro-electronics, implantable medical devices, precision connectors

Head-to-Head Comparison Matrix

Making the Strategic Choice: Key Decision Factors

1. Volume vs. Variety Analysis

- If you produce >100,000 identical parts: Die-cutting likely wins on pure economics

- If you have 10+ product variations with moderate volumes: Ultrasonic offers balance

- If you have high mix, low volume, or frequent design changes: Laser is transformative

2. Product Criticality Assessment

- Commodity parts with loose tolerances: Die-cutting sufficient

- Clean rooms or contamination-sensitive applications: Ultrasonic preferred

- Mission-critical components with micro-features: Laser mandatory

3. Total Cost of Ownership Perspective

Beyond initial investment, consider:

- Tooling storage and management costs

- Scrap rates from damaged parts

- Changeover downtime costs

- Quality inspection and rework expenses

- Future-proofing against design changes

4. Industry 4.0 & Digital Transformation

If your strategy includes:

- Digital twin implementation

- Rapid prototyping integration

- Mass customization capabilities

- Real-time quality monitoring

- Automated data collection

Laser technology aligns perfectly with these future-facing initiatives.

The Future Trajectory: Where Runner Separation Is Heading

Hybrid Systems are emerging, combining laser precision with ultrasonic final finishing for perfect surfaces.

AI-Powered Laser Systems now automatically detect runner positions, adjust parameters in real-time, and predict maintenance needs.

Integrated Micro-Finishing allows laser systems to not only separate runners but also perform micro-deburring and surface texturing in the same operation.

Sustainability Focus drives preference toward methods with less material waste (laser typically wastes 0.1% vs. 1-3% for mechanical methods).

Conclusion: Beyond Cutting—Strategic Value Creation

The choice of runner separation technology is no longer merely a technical decision—it's a strategic business choice that impacts:

- Time-to-Market – How quickly can you adapt to design changes?

- Quality Reputation – What defect rates can you guarantee?

- Production Flexibility – How easily can you handle customization?

- Workforce Development – What skills are you building for the future?

- Sustainability Profile – How much material are you truly saving?

While die-cutting remains the workhorse for stable, high-volume production, and ultrasonicprovides excellent solutions for specific applications, laser separation technology represents the future of agile, precise, and intelligent manufacturing.

The most forward-thinking manufacturers are already adopting a mixed-technology approach, applying each method where it provides maximum value across their product portfolio.

Ready to optimize your runner separation process? Contact our engineering team for a personalized assessment of your specific application needs, complete with ROI analysis and implementation roadmap.

Stay connected for more insights into advanced manufacturing technologies. Follow us on LinkedIn for weekly deep dives into precision manufacturing innovations.