Cooling in Injection Molds: A Beginner’s Guide

When we talk about injection molds, one of the most critical factors affecting part quality, cycle time, and tool life is cooling. But beginners often wonder: Does every mold need cooling? How does it work? What about smaller mold components like inserts or pins? Let’s break this down clearly.

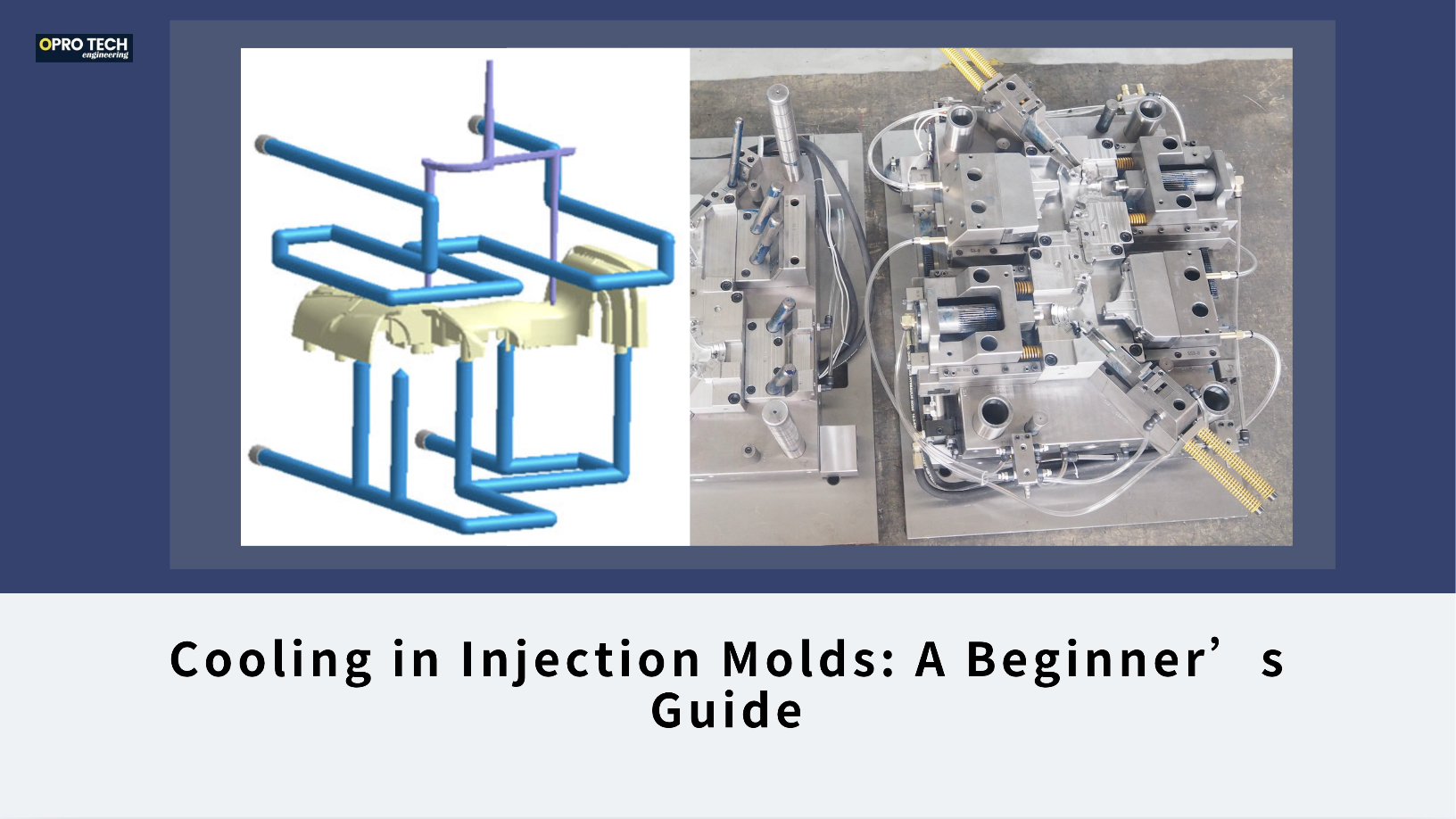

1. What Does “Cooling” Mean in Molds?

During injection molding, hot molten plastic (often at 200–300°C) is injected into the mold cavity. To solidify the plastic into the required shape, the mold must remove heat quickly and evenly.

This is achieved by circulating a cooling medium — usually water — through channels in the mold steel.

- With cooling: The mold has dedicated cooling channels designed to circulate water (or sometimes oil).

- Without cooling: Some small or simple molds may rely on natural heat dissipation through the steel into the air, though this is less efficient.

2. Does Every Mold Require Cooling Channels?

Not always. It depends on the part size, geometry, material, and production needs:

- High-volume production molds → Always require efficient cooling (water channels, conformal cooling, etc.) to reduce cycle time.

- Low-volume or prototype molds → Sometimes skip cooling channels if the part is small or if cycle time isn’t a concern.

- Thick-walled parts → Require carefully designed cooling channels to avoid shrinkage, warpage, or long cooling times.

👉 In short: Most production molds need cooling, but not all molds.

3. Do Other Mold Elements (Inserts, Pins, Cores) Need Cooling Too?

Yes — and this is where things get interesting.

Common elements that may require extra cooling:

- Core inserts (thin and tall cores heat up quickly).

- Ejector pins (especially when in contact with molten plastic for long periods).

- Slide inserts or lifters (small steel areas that trap heat).

How are these cooled?

- Water channels: Small drilled circuits running close to the insert.

- Bubblers: Small tubes inserted to circulate water into tight spaces.

- Baffles: Thin plates inserted into channels to direct water flow into difficult-to-reach areas.

4. Is the Cooling Water Shared or Separate?

It depends on the mold design:

- Main cooling system: Typically, the mold has a network of water circuits connected to a temperature control unit (TCU) that circulates water continuously.

- Separate cooling for inserts/pins: Sometimes inserts, cores, or special elements are given dedicated cooling lines, independent from the main mold cooling loop.

👉 The goal is to control the temperature balance of the entire mold, so some areas may share water circuits, while others are separated for more precise control.

5. Why Does Steel Selection Depend on Cooling?

Now let’s link this to an example:

- If no cooling:

The steel must withstand higher, uneven thermal stresses. Therefore, harder tool steels (e.g., 1.2312, 1.2343) are chosen, which can handle heat cycles better. - If cooling is present:

Heat is managed more effectively, so corrosion resistance becomes important (since water is circulating inside the mold). That’s why stainless steels (e.g., 1.2083, 1.4125) are used for molding elements.

6. Key Takeaways for Beginners

- Cooling = heat removal via circulating water (sometimes oil).

- Not all molds need cooling, but most production molds do.

- Mold inserts, cores, and pins may need separate cooling circuits (bubblers, baffles, or small channels).

- Cooling circuits may be shared or separate, depending on temperature balance requirements.

- Steel choice depends on cooling presence → hardened steels for no cooling, stainless steels when cooling is applied.

7. Why It Matters

Efficient cooling =

✅ Shorter cycle time (faster production)

✅ Better dimensional stability (less warpage/shrinkage)

✅ Longer mold life

✅ Lower energy costs

For a beginner, just remember: Cooling is as important as injection itself — it’s the invisible factor that often decides whether a mold is good or bad.

Factory add: No 39, Zhen an west road, Changan town , Dong guan city, China.