Will the No. 45 steel workpiece be deformed after final carburization after processing?

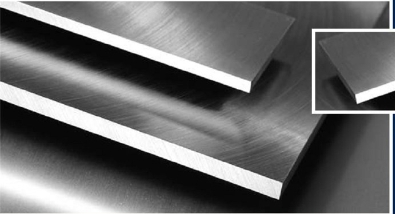

No. 45 steel is a type of carbon structural steel commonly used to manufacture mechanical parts and engineering components. Carburizing is a common surface treatment in which carbon is introduced to the surface of steel to increase hardness during heat treatment.

Generally, left rear carburizing (left rear heat treatment) is unlikely to cause deformation of No. 45 steel workpieces. This is because carburizing is usually carried out at higher temperatures and the process is carried out evenly over the entire workpiece.

So why do some cause deformation?

Control of heat treatment parameters: Control of heat treatment parameters such as temperature and time is very important to ensure the dimensional stability of the workpiece. Precise control of these parameters reduces the risk of deformation.

Workpiece geometry: Complexly shaped workpieces may be more susceptible to deformation. When designing the workpiece, consideration can be given to reducing the build-up of internal stresses, thereby reducing the possibility of deformation.

Cooling process: The heat-treated workpiece needs to go through an appropriate cooling process. Rapid cooling may result in non-uniformity of the workpiece, causing deformation. Ensuring proper cooling methods are used is key.

I think as long as we pay attention to details during the production process, we can avoid the deformation of the No. 45 steel workpiece during the carburizing process. What do you think?