Exploring Fillets and Chamfers: The Subtle Differences in Machining

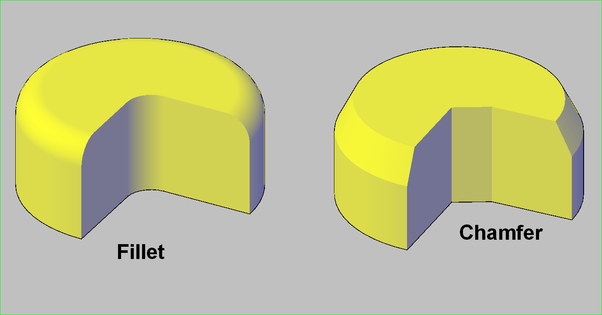

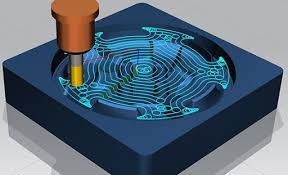

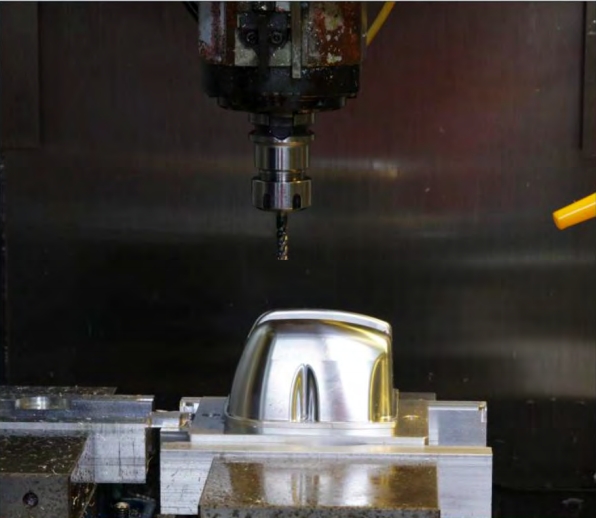

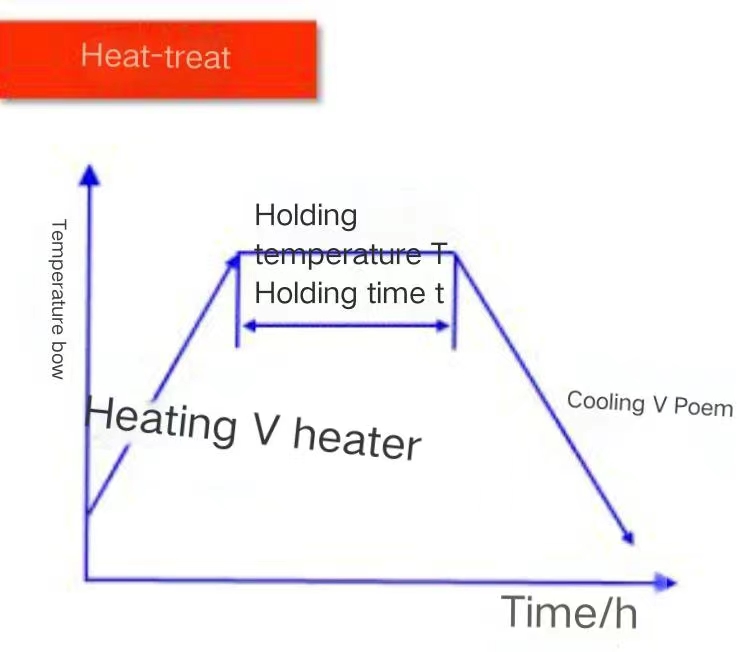

In engineering design and manufacturing, fillets and chamfers are two common yet often confused concepts. While both are used to address edges, their functions and forms have subtle differences. Let's...