Arc Welding with Electrode: Sparking Connections Between Metals

Arc welding with electrode is a widely used welding technique in the field of metal connections. By utilizing the high temperature of the electric arc and melting the electrode, it securely binds workpieces, making it an indispensable part of many manufacturing and repair processes.

Working Principle:

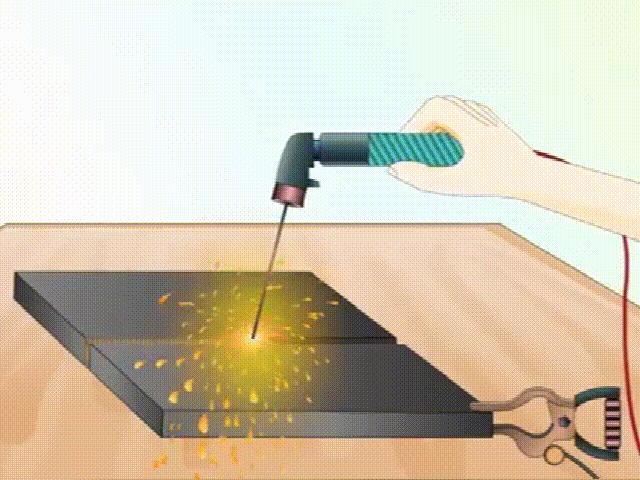

The fundamental principle of arc welding with electrode lies in generating a high-temperature electric arc through electric current. This arc melts both the electrode and the workpiece, creating molten metal that forms a strong connection once cooled. This process requires specialized welding equipment, including a welding machine and corresponding safety gear.

Equipment and Materials:

Welding Machine: Arc welding necessitates a welding machine capable of providing the required current and voltage to maintain a stable electric arc.

Electrode: The electrode is a crucial material in the welding process, selected based on the desired welding characteristics and specifications.

Welding Steps:

Preparation: Ensure the work area is clean, safe, and equipped with appropriate protective gear such as a welding face shield, gloves, and protective clothing.

Set Up the Welding Machine: Adjust the current and voltage parameters of the welding machine according to the type and requirements of the workpiece.

Prepare the Electrode: Ensure the selected electrode is suitable for the work material and, if necessary, bake it before use.

Arc Ignition: Use an ignition device to initiate the electric arc, ensuring it forms between the electrode and the workpiece.

Considerations:

Safety First: Ensure good ventilation in the welding area and keep away from flammable materials. Wear appropriate protective gear, including a welding face shield, gloves, and safety shoes.

Choose the Right Electrode: Select the correct electrode based on the type of workpiece and the desired welding characteristics.

Control Current and Voltage: Ensure the welding machine's current and voltage settings are correct to achieve the desired welding results.

Arc welding with electrode is a powerful and versatile welding technology widely employed in construction, manufacturing, and repair fields. With the right equipment and operations, arc welding with electrode can ignite creative sparks between metals, permanently connecting them.