What is Direct Metal Printing(DMP)?

Direct metal printing (DMP), also commonly known as direct metal laser sintering (DMLS), is an additive manufacturing technology that builds high-quality complex metal parts from 3D CAD data.

In the machine, a high-precision laser is directed to metal powder particles to selectively build up thin horizontal metal layers one after the other.

This cutting-edge technology allows for the production of metal parts with challenging geometries, not possible using traditional subtractive or casting technologies.

Direct Metal Printing (DMP)

Use this technology to improve functionality, reduce weight, and/or consolidate components into one single part.

A direct metal printing (DMP) metal 3D printer uses a laser to weld thin layers of metal powder to produce highly complex metal parts.

DMP provides unlimited design flexibility and overcomes traditional manufacturing technique limitations for geometry and surface retention.

Manufacturing costs for parts are not dependent on part complexity but rather, on part volume.

DMP is ideal for producing compact components with highly complex anatomical shapes, internal channels, complex surface textures, internal lattices, and high levels of detail.

Additive and subtractive technologies can be combined for the most effective cost per part.

DMP Applications

Our DMP printers allow you to create metal parts while achieving fine detail, which is why DMP is perfect for a variety of applications.

This includes, but is not limited to:

· Producing complex parts that cannot be made using traditional methods

· Conformal cooling channels and latticework

· Enhanced fluid flow

· Direct tool-free production of injection molding inserts and cores

· Mass personal customization of orthopedic, dental, and other parts

· Parts with cavities, and undercuts. and draft angles

· Reduced-weight and light-weight design

· Research and development

· Simplified assemblies and part consolidation

· Small, precision parts production

· Topology optimization while maintaining structural integrity

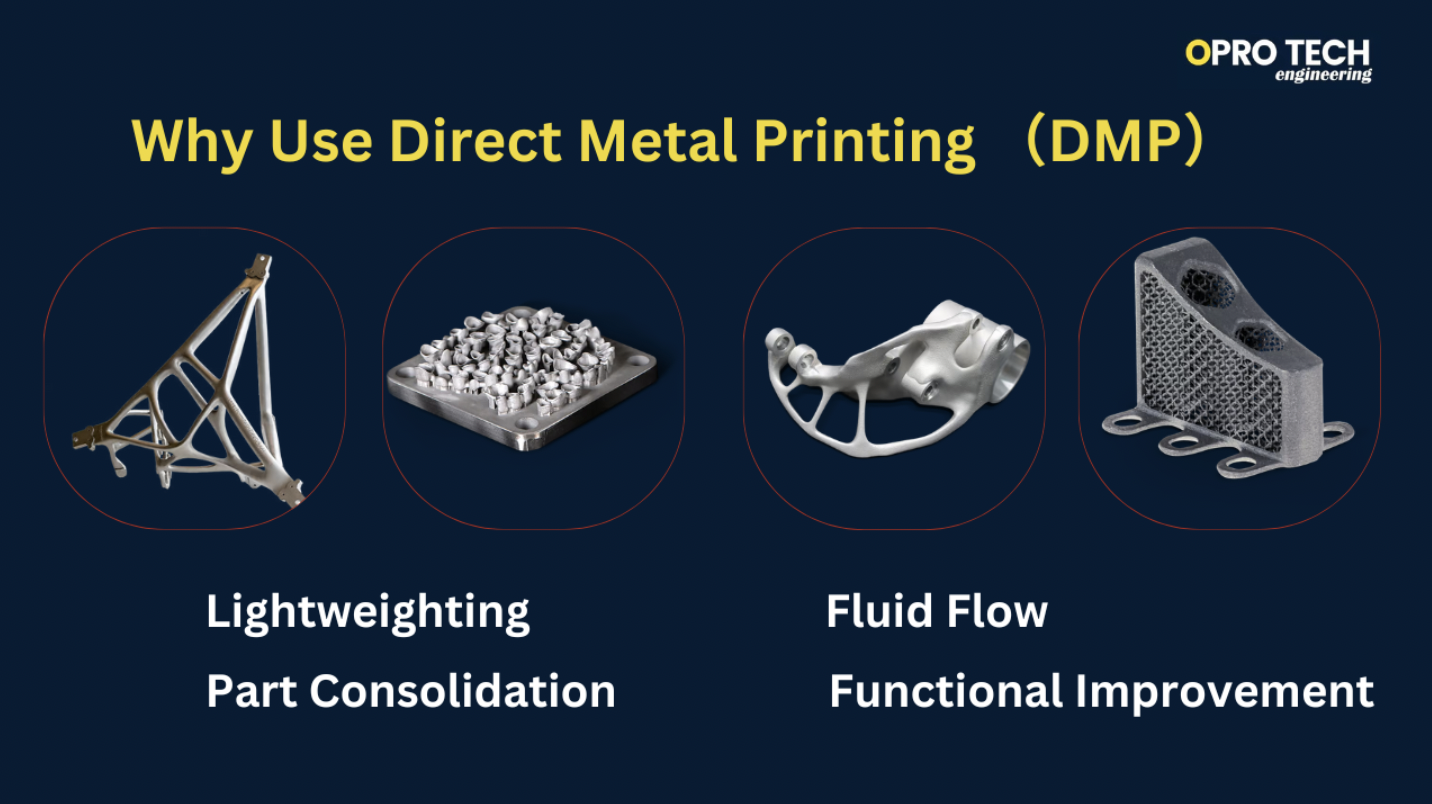

Why Use Direct Metal Printing?

- Lightweight

Reduce weight, and improve stiffness-to-weight ratio through topological optimization, hollowing, applying internal lattice structures, and/or consolidating assemblies to reduce fasteners.

- Part Consolidation

Manage your part count and eliminate critical assembly processes such as welding that require extensive quality control and inspection. Reduce assembly time and cost by eliminating the need of sub-assembly labor and jigs and fixtures

- Fluid Flow

Rethink design and enable fluid and airflow design to achieve the best cooling, heating, mixing, or other fluid flow in a part. Make the best of use of CFD by producing geometries that are truly optimized for fluid dynamics and not achievable with conventional production technologies.

- Functional Improvement

Design outside the subtractive toolbox and increase the functionality of your component or product by making use of the design freedom metal AM offers.

Thanks for reading, The above information is credited to:

3D Systems Corporation