[Case Study] Shipping Plastic Parts with Embedded Magnets: The Unexpected Challenge We Faced with Magnetism Test Requirements

![[Case Study] Shipping Plastic Parts with Embedded Magnets: The Unexpected Challenge We Faced with Magnetism Test Requirements](/uploads/opro-engineering/20250603/3891dded-67f0-41da-b59e-e6c1979829fe.png )

📦 The Situation

We recently shipped a batch of 350 plastic components, each ultrasonically welded with a small but strong neodymium magnet inside, to a client overseas who urgently needed the parts for a product launch. We carefully packaged the components and arranged express shipping via DHL, expecting fast delivery.

However, shortly after pickup, DHL notified us that the parcel had been held due to failure in a magnetism check test — a requirement we hadn’t fully accounted for.

🧲 What Is the Magnetism Check Test?

The magnetism check is a mandatory test for goods shipped via air freight that contain permanent magnets or components with magnetic properties. The primary reason for this test is aviation safety.

According to the International Air Transport Association (IATA):

“If the magnetic field strength at a distance of 2.1 meters from the surface of the package exceeds 0.00525 gauss, the package is considered a ‘Magnetized Material’ and may pose a hazard to aircraft navigation systems.”

Magnetic fields this strong can interfere with aircraft instruments, including compasses and flight control electronics, which is why they are strictly regulated.

🇨🇳 Chinese Government Regulations

In China, customs authorities and shipping agents like DHL follow IATA regulations closely. Goods that are found to have excessive magnetic field strength may be:

- Held by customs until a Magnetic Test Report (磁性测试报告) is provided

- Required to be repackaged or shielded

- Rejected from air freight and forced to be rerouted via sea or land

This process can cause serious delays, especially for urgent shipments.

❗ What Went Wrong in Our Case?

The plastic parts themselves were non-problematic. However, the magnet inside was not shielded, and when measured at DHL’s export inspection center, the magnetic field exceeded the safety threshold.

As a result, DHL withheld the package and notified us that customs clearance could not proceed unless the magnetism was addressed.

🛠️ How We Solved It

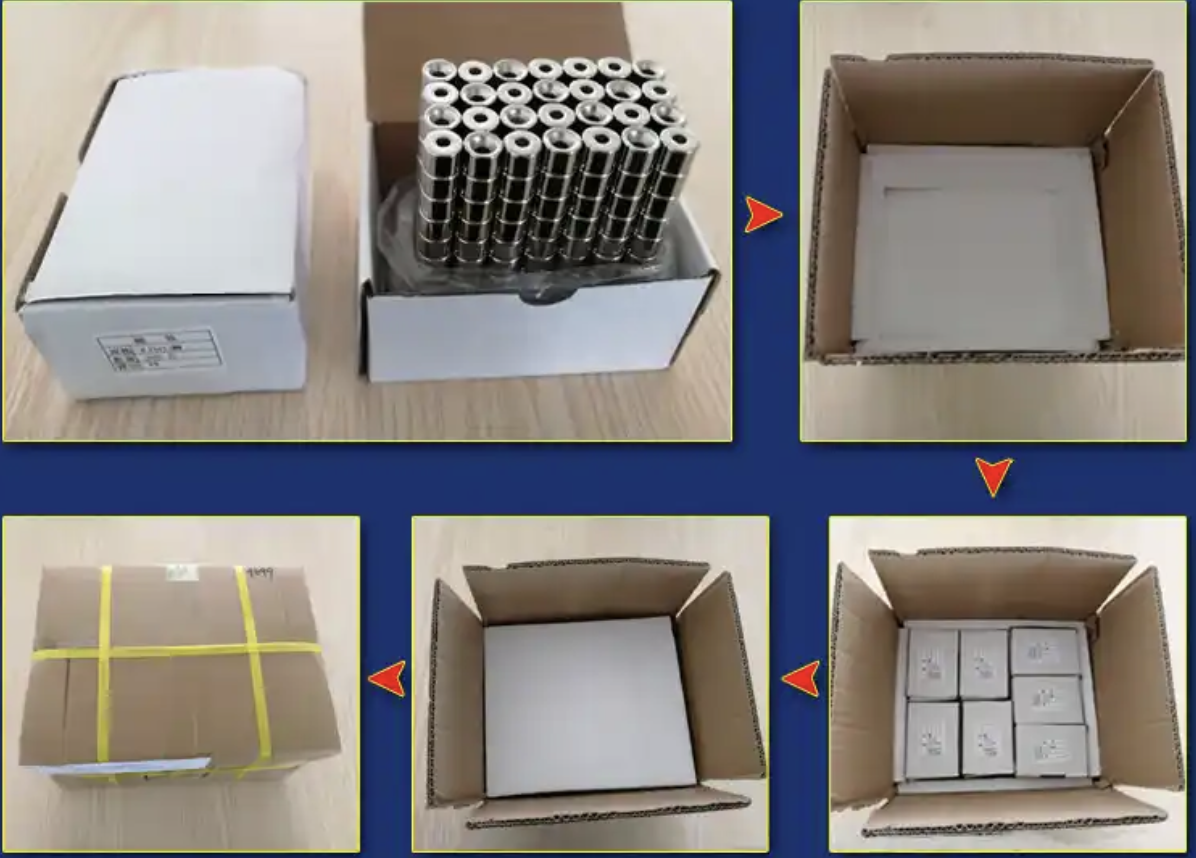

We quickly acted on DHL’s advice to repack and shield the shipment. Here’s how we resolved the issue step-by-step:

1. Split the Quantity

We separated the original shipment into multiple smaller boxes. Fewer magnets per box meant lower cumulative magnetic field strength.

2. Used Foam Padding

Each batch of components was placed in foam boxes to prevent parts from sticking together or shifting during transit — which can intensify magnetic fields.

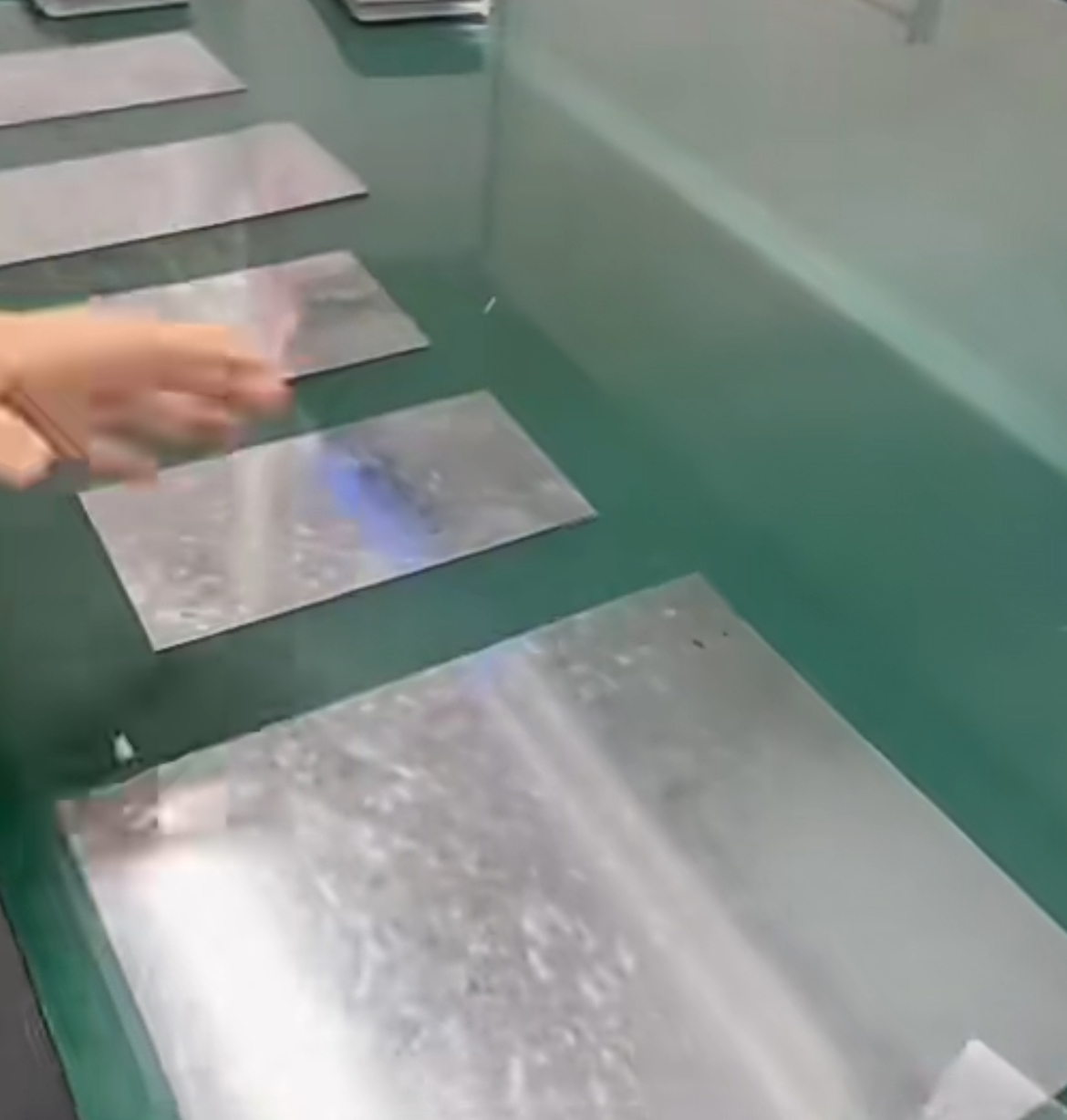

3. Added Magnetic Shielding

We wrapped the foam boxes with iron sheets, a method known to effectively redirect magnetic fields and contain them. This helped reduce the field strength measured outside the packaging.

4. Re-Tested the Packages

The repackaged boxes were then re-submitted for magnetism testing. This time, all boxes passed the 2.1m test and were cleared for air transport.

5. Prepared a Magnetism Test Report

We obtained a formal Magnetic Field Strength Report from a third-party certified lab to provide to customs and DHL for future reference.

📘 What We Learned

This case taught us that even small, hidden magnets can cause big logistical issues if not properly managed. For any product containing magnets — especially strong rare-earth magnets — we now follow this checklist:

- ✅ Pre-shipment magnetism test

- ✅ Use of iron shielding materials

- ✅ Packing in smaller quantities

- ✅ Preparation of a formal magnetism report

- ✅ Close communication with logistics partners

📈 A Message to Our Clients

We are committed to not only delivering quality parts, but also ensuring they are shipped safely, efficiently, and in full compliance with global transport regulations.

If your product involves magnets, batteries, or sensitive electronics, please let us know in advance. We'll work with you to plan the safest, fastest delivery route — without surprises.

📞 Need Help with Magnet-Embedded Components?

Our team has hands-on experience with plastic parts, magnetic assembly, and international logistics. If you are looking for a reliable partner who understands both manufacturing and shipping, feel free to contact us.

📧 Email: [danny@opro-tech.com]

🌐 Website: [www.opro-tech.com]