What is PVD?

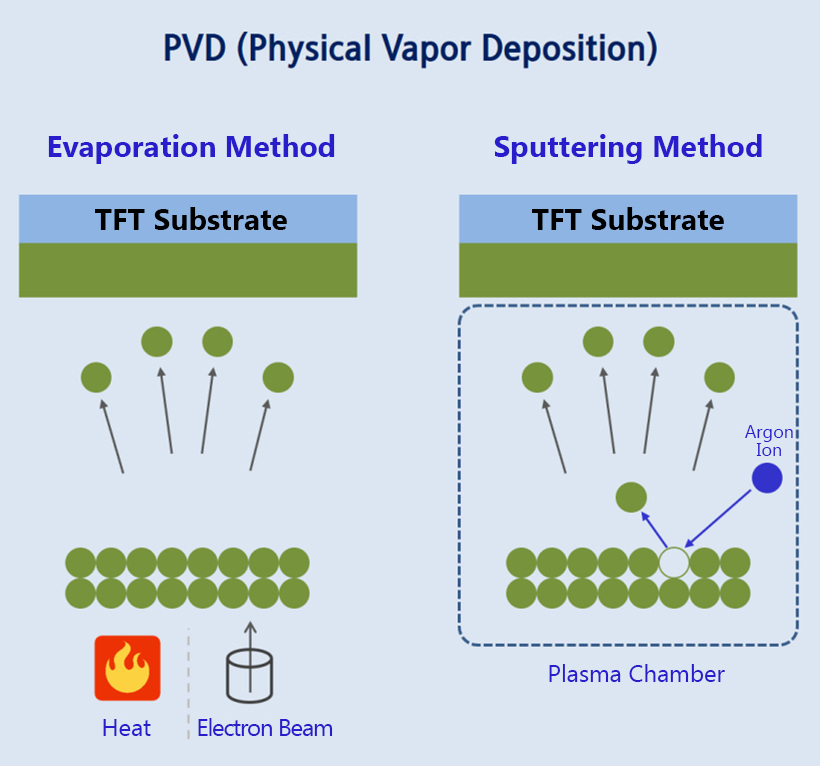

In fact, it is a type of coating technology, which mainly uses physical methods to heat or stimulate material processes to deposit thin films.

What should you pay attention to before PVD coating processing?

1. Cleaning: The first step in the PVD coating process is to clean the substrate, the material to which the coating is to be applied. This involves using various methods, such as mechanical or chemical cleaning, to remove any dirt, debris or other contaminants on the surface of the substrate. This is important because any impurities on the surface of the substrate will affect the quality of the coating.

2. Pretreatment: The next step is pretreatment, which includes treating the substrate to improve coating adhesion. This may include processes such as anodizing or plasma etching, which create a rough surface on the substrate, making it easier for the coating to adhere.

3. Coating: The third step is the actual PVD coating process, which involves heating source materials such as metals or ceramics to high temperatures until they evaporate. The evaporated material is then deposited onto the substrate to form a thin, uniform layer. The coating process usually takes place in a vacuum chamber, which helps prevent the vaporized material from reacting with any air or other gases.

4. Quality Control: After the coating is applied, it is inspected to ensure it meets the required specifications. This may involve various tests, such as measuring the thickness of the coating or testing its hardness and durability.

5. Finishing: The final step is finishing, which involves applying additional treatments to the coated substrate, such as polishing or buffing, to improve its appearance or performance. This can include processes such as surface finishing or coloring, which can enhance the visual appeal of the coated product.