What is MUD The Master Unit Die Quick-Change?

Ok it’s absolutely mind-blowing to discover the MUD system—The Master Unit Die Quick-Change. I'm not certain when the MUD system was invented, but as a new comer to this field, 💡✨ It's incredible to witness the innovation that drives efficiency and sustainability. 🌐💪

MUD represents a paradigm shift, showcasing how rethinking traditional methods can lead to remarkable improvements in tooling changeovers, downtime reduction, and cost-efficiency. The manufacturing landscape is a dynamic realm that demands constant evolution and fresh perspectives. 🔄🛠️

Embracing innovative approaches like MUD not only streamlines processes but also reflects a commitment to creating a more agile, responsive, and eco-friendly manufacturing ecosystem. 🌱💼 Kudos to the minds behind such groundbreaking concepts that shape the future of production! 🚀🌍

Here's some information about MUD for reference, or you can obtain first-hand information by visiting https://www.dme.net/mud/.

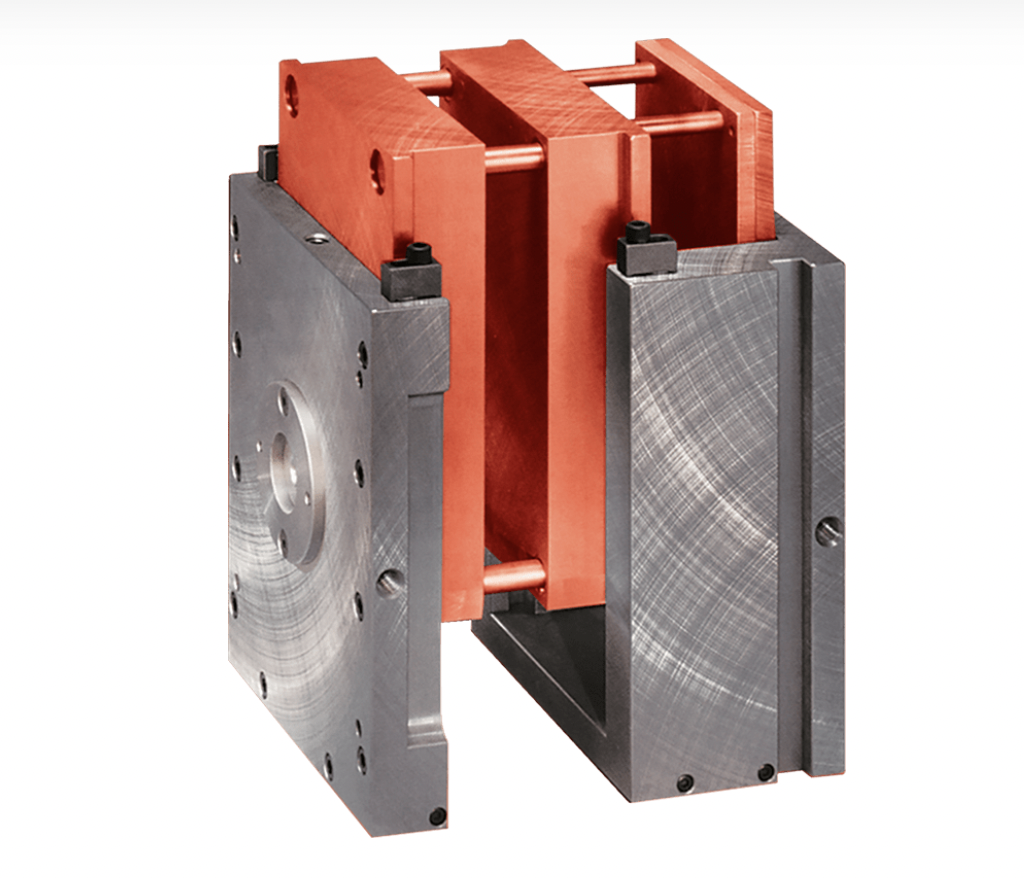

the Master Unit Die Quick-Change (MUD) system is a standardized mold base concept that allows for quick tooling changes in injection molding. The MUD system is designed to simplify and accelerate the process of changing molds in the production of plastic parts. It consists of standardized mold bases and interchangeable mold inserts.

The key features of the MUD system include:

Interchangeable Inserts: The mold base is designed to accept interchangeable inserts, allowing for easy and rapid changes to the core and cavity of the mold.

Standardization: The MUD system follows standardized specifications, enabling compatibility and interchangeability between different molds and molding machines.

Reduced Downtime: One of the primary advantages of the MUD system is the significant reduction in downtime during mold changes. This results in increased overall productivity.

Versatility: The system is versatile and applicable to a wide range of part sizes and configurations, making it suitable for various injection molding applications.

Cost-Efficiency: By standardizing mold components and reducing changeover time, the MUD system contributes to cost savings in tooling and production.

Ease of Use: The standardized design simplifies the process of designing, manufacturing, and implementing molds, making it more accessible for manufacturers.

Overall, the MUD system is a valuable tool for manufacturers looking to enhance efficiency, reduce costs, and increase flexibility in their injection molding operations.

Hats off to those who contribute to the field of manufacturing! 👍

While the Master Unit Die Quick-Change (MUD) system offers several advantages in terms of quick tooling changes, reduced downtime, and cost-efficiency, its widespread adoption depends on various factors. Here are some reasons why not all factories use the MUD system:

Initial Investment: Implementing the MUD system requires an initial investment in standardized mold bases and inserts. Some factories may be hesitant to make this investment, especially if they already have existing molds and tooling that follow different standards.

Existing Tooling: Factories with a substantial investment in traditional tooling may find it challenging to transition to the MUD system. Converting existing molds to fit the MUD standard could be cost-prohibitive.

Specific Requirements: Certain industries or applications may have specific molding requirements that are better addressed by custom tooling. In such cases, a standardized system like MUD may not offer the level of customization required.

Production Volume: The benefits of the MUD system are more pronounced in high-volume production scenarios where quick changeovers can significantly impact efficiency. In lower-volume production, the advantages may not be as compelling.

Resistance to Change: Some manufacturing facilities may resist adopting new systems due to concerns about disruption, retraining of personnel, and uncertainties about how the change will impact existing processes.

Mold Complexity: The MUD system is well-suited for relatively simple molds. However, for highly complex molds or those requiring specialized features, a more customized approach may be preferred.

While the MUD system aligns with lean manufacturing principles, the decision to adopt it depends on the specific needs, priorities, and circumstances of each manufacturing facility. Some industries and companies have successfully embraced MUD, reaping the benefits of increased flexibility and efficiency in their injection molding processes.