Understanding the Wedge Block in Injection Molds

The Hidden Element That Ensures Precision

In injection mold design, many components may appear simple or insignificant at first glance, yet they quietly determine the quality, precision, and long-term durability of the mold. One such component is the wedge block, commonly referred to in many mold shops as the “tightening block.”

Despite its modest appearance, it plays a crucial role in ensuring proper cavity alignment, stable parting-line sealing, and consistent molding performance.

This article provides a clear and comprehensive explanation of what a wedge block is, how it works, and why it matters.

1. What Is a Wedge Block?

A wedge block is a fixed, non-moving, wedge-shaped steel element built into the mold to provide sideward tightening or diagonal compression during mold closing.

Its main functions include:

- Applying side pressure to an insert, cavity block, or core block

- Ensuring parting line surfaces are tightly sealed

- Stabilizing the position of floating or movable inserts

- Enhancing overall mold rigidity

- Reducing or eliminating flash during molding

Common industry terms:

- Wedge Block

- Angle Block

- Side Wedge

- Tightening Block (shop-floor terminology)

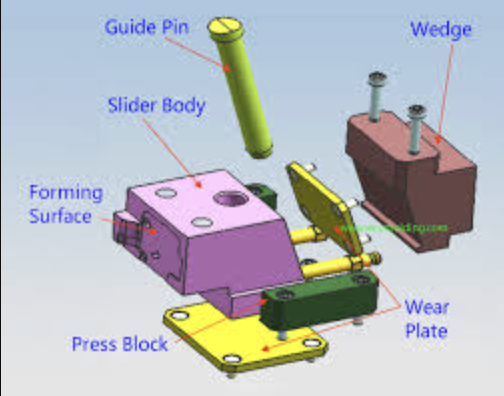

2. Structural Characteristics

Even though it provides movement-related functionality, the wedge block itself is completely fixed in the mold structure—usually secured tightly with screws and sometimes dowel pins.

Key features:

- Fixed installation

- Precisely machined angled surface

- High-strength steel for pressure resistance

- Works by interacting with another movable insert

- Designed to handle high, repeated tightening forces during molding

The block itself doesn’t move. Its angled surface is what generates controlled movement in other components.

3. How Does a Wedge Block Work?

The working principle can be summarized simply:

The wedge block stays still — the insert it contacts moves.

During mold closing:

- The movable insert slides forward with the closing action.

- It makes contact with the wedge block’s angled surface.

- The angled surface forces the insert to shift sideways or diagonally.

- This movement provides the final tightening needed for a perfect cavity seal.

A simplified illustration:

This mechanism ensures that even complex, multi-insert cavity layouts can achieve precise, gap-free closing.

4. Why Use an L-Shaped Arrangement?

You mentioned your workshop uses an L-shaped wedge block layout.

This is common in molds requiring additional diagonal tightening.

Benefits of an L-shaped arrangement:

- Provides diagonal or corner-direction tightening

- Improves overall cavity balance

- Reduces single-direction stress concentration

- Ideal for thin-wall parts or parts with demanding sealing requirements

- Helps stabilize large or asymmetrical cavity blocks

This design enhances both accuracy and mold durability.

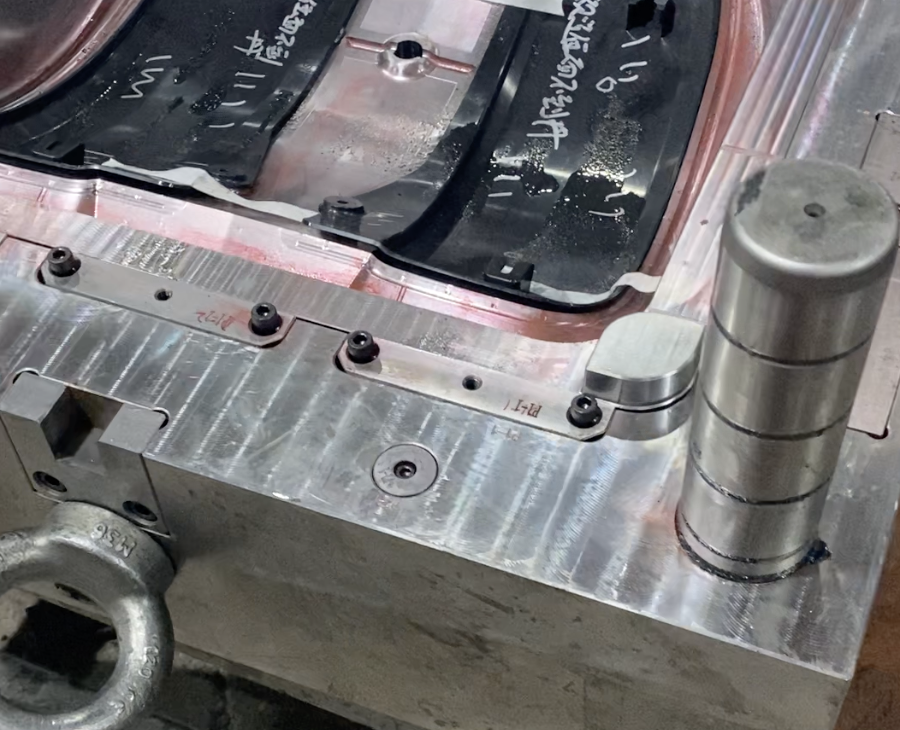

5. Typical Applications

Wedge blocks are used widely in:

- Precision aesthetic parts

- Thin-wall components

- Molds with multiple inserts or floating cores

- Mold designs requiring diagonal sealing force

- Large surface sealing areas

- High-volume production molds where repeatability is critical

They are especially important when even a small gap can lead to visible defects or flash.

6. Key Advantages of Wedge Blocks

✔ Improved cavity alignment

Better sealing and reduced flash.

✔ Stabilization of movable inserts

Prevents insert shifting during molding cycles.

✔ Enhanced mold rigidity

Supports cavity closing forces from multiple directions.

✔ Longer mold life

Reduced wear, fewer mismatches, and more consistent operation.

7. Manufacturing & Assembly Considerations

Because the wedge block plays a functional and structural role, certain manufacturing details are critical:

(1) Angle Accuracy

Common angles: 5°, 7°, 10° — angle precision directly affects tightening force.

(2) Ground Surface Finish

Ensures smooth contact with the movable insert and avoids wear.

(3) Secure Locking During Assembly

Screws, dowel pins, or anti-loosen structures are needed due to high closing forces.

(4) Proper Insert Guide Design

The mating insert must be designed to slide smoothly without interference.

These details determine long-term mold stability and performance.

8. Precision Lies in the Details

The wedge block may be small and easily overlooked, but it plays an outsized role in mold performance:

- Ensuring tight cavity sealing

- Stabilizing insert movement

- Improving part consistency

- Enhancing mold strength and lifespan

Our continuous attention to components like the wedge block reflects a simple principle:

In moldmaking, true quality comes from mastering the hidden details—not just the visible structures.

It’s this level of attention and craftsmanship that allows us to deliver molds that are not only precise but also reliable and durable in long-term mass production.