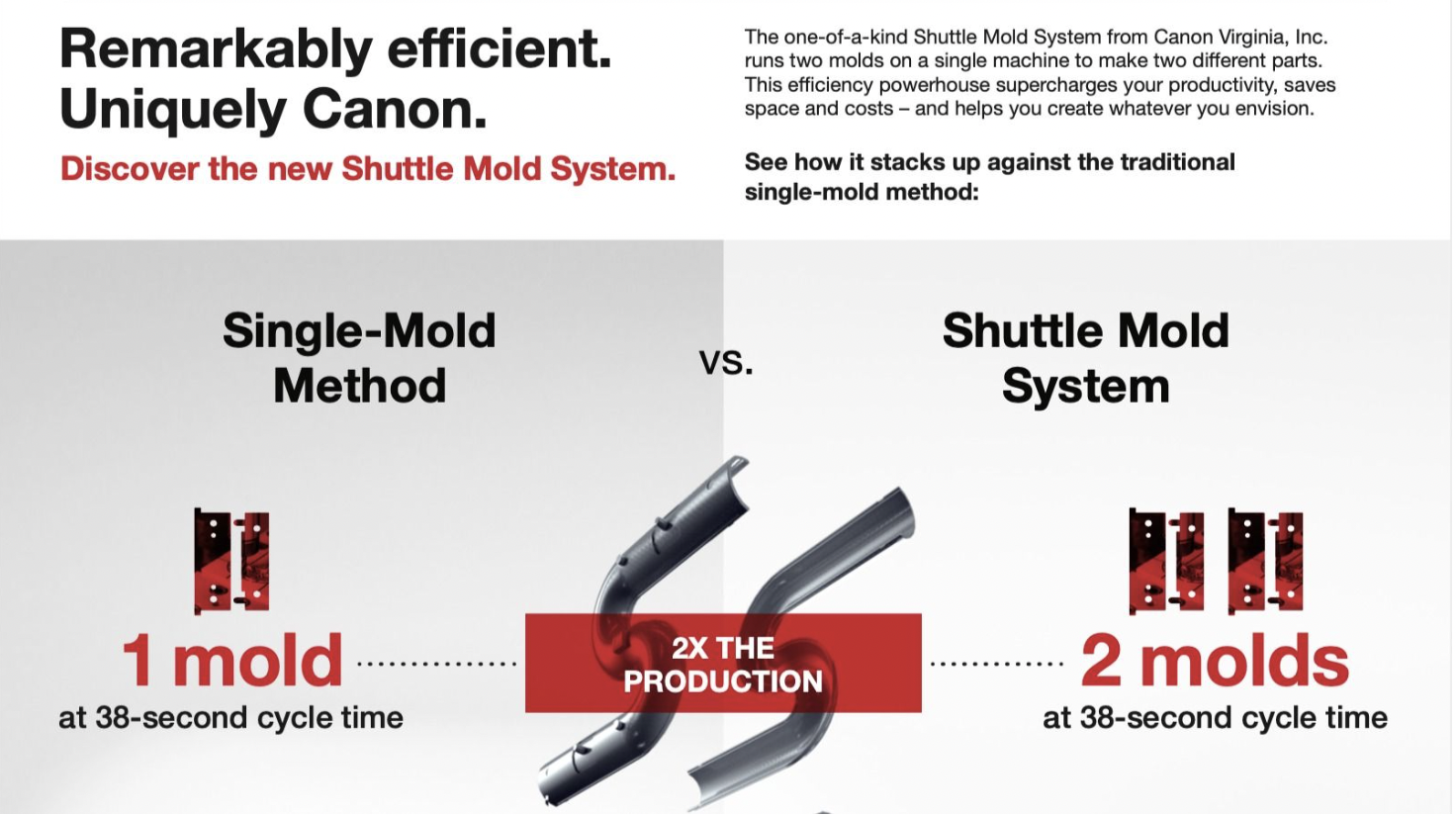

What is shuttle mold system?

🌟 🌟 🌺 It's fascinating to discover that #cannon is involved not only in manufacturing cameras and printers but also in injection molding and tooling for injection molding.

This may reshape the perception many have about Cannon, associating it solely with consumer electronics. 🍾 🎊 🎉

In my recent research on #shuttlemolds, I came across an interesting piece of information related to Cannon's shuttle system. I've summarized my findings below for your reference. If you're intrigued by Cannon's shuttle system, you can explore further by clicking on the link shared below. 🤔 🤔

https://lnkd.in/gs7MbSNx

👩 👩 Feel free to check it out and delve into the world of Cannon's innovations in injection molding and tooling.

A #shuttlemold in injection molding refers to a mold system with one A-side and multiple B-sides. It is commonly used in a vertical clamping press, as opposed to a horizontal clamping press. The vertical clamping press is ideal for over molding or insert molding applications.

📣 📣 Advantages of using a shuttle mold in the injection tooling industry include:

✅ Increased Productivity: Shuttle molds can enhance productivity by allowing one side of the mold to be engaged in molding a part while the other side is used for unloading and loading inserts. This reduces downtime between cycles.

✅ Versatility: The design of shuttle molds is particularly useful for over molding and insert molding, where additional components or inserts are added to the mold during the molding process.

✅ Flexibility in Material and Color Changes: Shuttle molds facilitate easier material and color changes because the mold can be loaded and unloaded independently of the molding process, making it more flexible for various production requirements.

✅ Operator Accessibility: In a vertical clamping press, the mold is easily accessible to the operator, simplifying the loading and unloading of inserts and improving overall efficiency.

✅ Automation Potential: While shuttle molds often involve manual operation, there is also potential for automation, especially when combined with robotic systems for insert loading and part unloading.

✅ Applicability to Specific Industries: Shuttle molds find applications in industries such as electronics, consumer goods, automotive, aerospace, and military/defense, where the specific advantages of shuttle molds, such as versatility and productivity, are beneficial.

#cannonusa #shuttlemolds #learningjourney #canonvirginia

Thanks for their great work! To know more shuttle mold system, please click https://cvi.canon.com/manufacturing-services/shuttle-mold to get first hand information.

Thanks.