Surface Roughness vs. Surface Finish: Two Key Differences in the Manufacturing Realm

In the manufacturing industry, surface roughness and surface finish are two closely related yet distinctly different concepts. These two factors directly impact the performance, appearance, and quality of parts. In this article, we will delve into the differences between surface roughness and surface finish and their unique roles in the manufacturing process.

Surface Roughness:

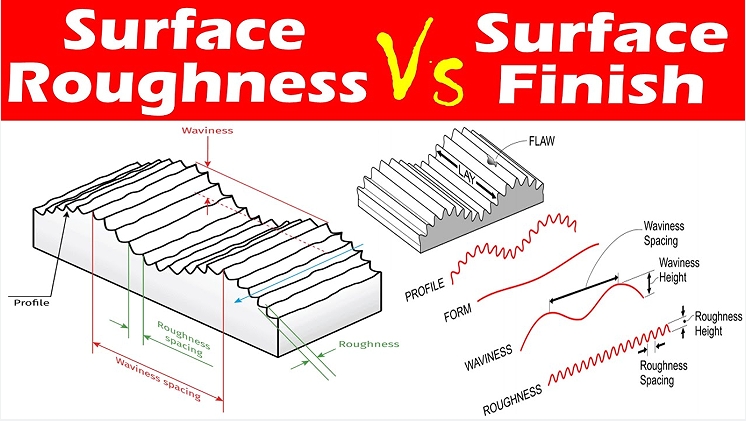

Surface roughness refers to the irregularity of an object's surface, typically measured in micrometers or nanometers. This parameter reflects the degree of unevenness on the surface and directly relates to performance factors such as friction, wear resistance, and sealing.

Differences:

Definition: Surface roughness is a quantitative description of surface irregularities.

Impact: It directly affects factors like friction, wear resistance, and sealing performance.

Measurement Unit: Typically measured in micrometers (μm) or nanometers (nm).

You can refer to the video:https://youtu.be/FPTebi0gnuQ?si=gWzihy_QQtjkVwba

Surface Finish:

Surface finish refers to the smoothness of an object's surface, often expressed through its reflective properties. In contrast to surface roughness, surface finish is directly related to appearance, tactile feel, and optical performance.

Differences:

Definition: Surface finish is a quantitative description of surface smoothness.

Impact: It directly affects appearance, tactile feel, and optical performance.

Measurement Unit: Typically measured using devices like optical microscopes or gloss meters.

Significance of Differences:

Application Areas: Surface roughness predominantly affects mechanical performance, while surface finish is more concerned with appearance and optical performance.

Manufacturing Goals: Controlling surface roughness aims to reduce friction and enhance wear resistance. Surface finish, on the other hand, aims to improve appearance and optical quality.

Measurement Methods: Surface roughness is commonly measured using a roughness gauge, whereas surface finish might involve tools like optical microscopes or gloss meters.

In a words,Surface roughness and surface finish play equally crucial yet distinctly different roles in the manufacturing process. Manufacturers, in their pursuit of optimal part performance and aesthetic quality, must consider and precisely control both parameters to ensure the final product achieves the desired level of performance and visual appeal.