What are the restrictions when applying stack molds into the tooling industry?

👋 Hi, have you designed stacked molds in your work? Is it popular in your country? Thank you for your sharing about stack molds. 🤔 🤔 Below is the general information for reference.

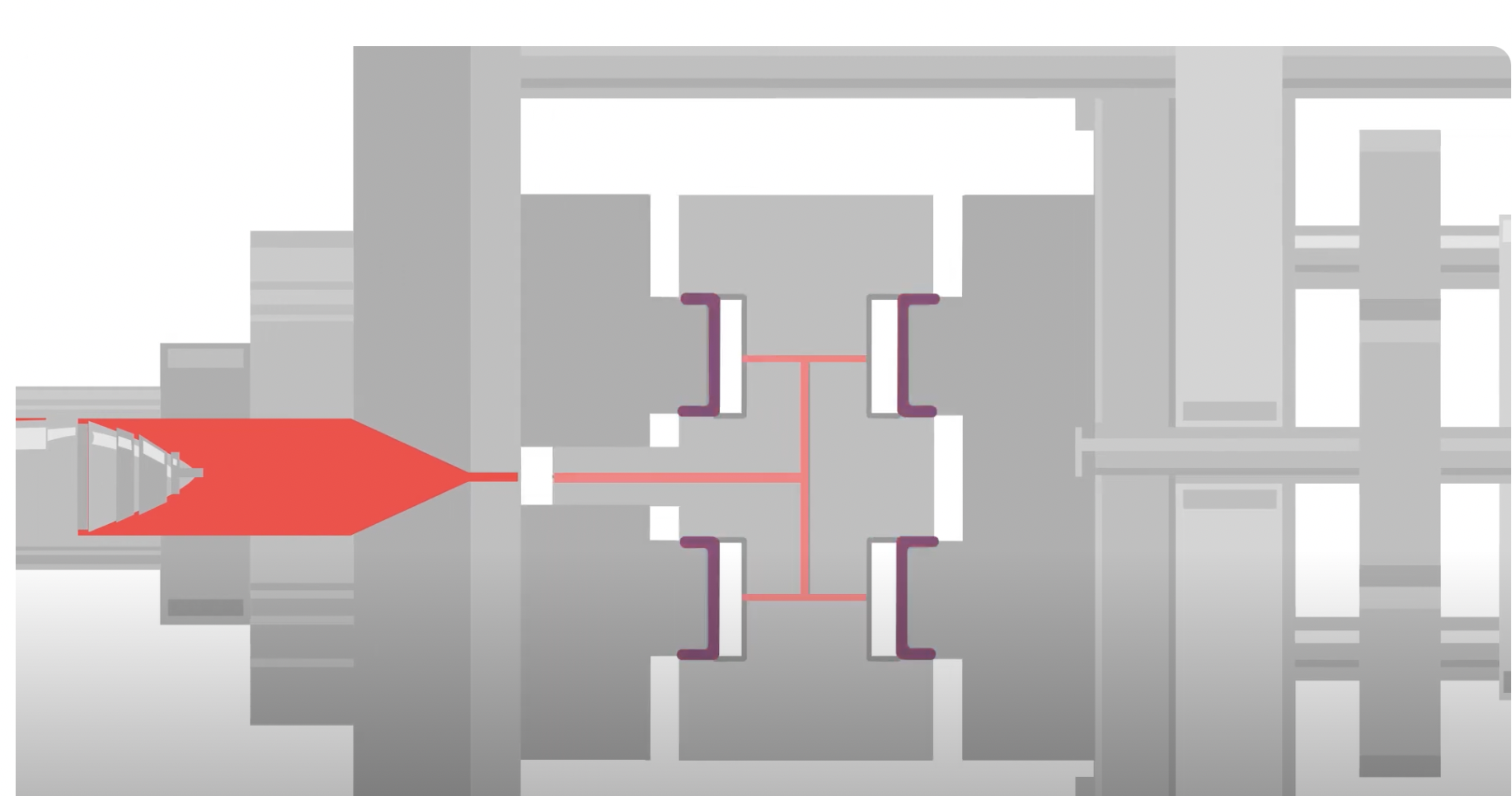

A stack mold, also known as a multi-layer mold or sandwich mold, is a type of injection mold used in plastic injection molding. It consists of multiple mold parting surfaces or layers, stacked on top of each other. Each layer contains cavities for molding parts. The stack mold can produce multiple identical or different parts in each cycle, depending on the number of layers.

Advantages of stack molds include:

Increased Production Output: Stack molds can produce double the number of parts in each molding cycle compared to a traditional single-face mold. This significantly increases production efficiency and output.

Cost Efficiency: Despite the initial higher cost of building a stack mold, the increased production output can lead to lower production costs per part. This cost efficiency is especially significant for high-volume production runs.

Reduced Floor Space: Stack molds allow for increased production without requiring a proportional increase in floor space. This is beneficial for manufacturers with space constraints in their production facilities.

Consistency in Part Quality: Stack molds ensure consistency in part quality, as each layer of the mold produces identical parts. This is crucial for industries where uniformity and precision are essential.

Versatility: Stack molds can be designed to produce identical or different parts in the same molding cycle. This makes them versatile and suitable for applications requiring different components in an assembly.

Reduced Cycle Time: The ability to produce multiple parts simultaneously reduces the overall cycle time, improving the efficiency of the injection molding process.

Energy Efficiency: Despite the increased complexity, stack molds can be energy-efficient due to the higher output per molding cycle, leading to reduced energy consumption per part.

While stack molds offer numerous advantages, it's essential to note that they are more complex and expensive to design and manufacture compared to traditional molds. The decision to use a stack mold depends on the specific production requirements, volumes, and cost considerations of the manufacturer.

Here are some considerations:

Complexity and Cost: Stack molds are more complex to design, manufacture, and maintain than traditional molds. The initial investment in a stack mold is higher, including engineering costs, machining, and assembly. This complexity and cost can be a limiting factor for some manufacturers, particularly those with smaller production volumes.

Space Requirements: Stack molds require more vertical space than single-face molds due to the multiple layers. Manufacturers with limited space in their production facilities may find it challenging to accommodate stack molds.

Cycle Time and Cooling: Cooling the plastic parts efficiently is crucial in injection molding. Stack molds can present challenges in terms of cooling, as the heat generated from the molten plastic in one layer can affect the adjacent layers. Proper cooling strategies must be implemented to maintain consistent part quality and cycle times.

Maintenance and Repairs: Maintenance of stack molds can be more intricate, and repairs may require specialized skills. Any issues with one layer of the mold can affect the entire stack, leading to downtime during repairs. Regular maintenance is crucial to ensure the long-term performance of stack molds.

Material Flow: Achieving uniform material flow across all layers of the stack mold is essential for consistent part quality. The design must account for the material's behavior during injection to prevent issues such as flow imbalances, short shots, or other defects.

Alignment and Tolerance: Precise alignment and tolerance control are critical in stack molds. Any misalignment or variation between layers can result in defective parts. Achieving and maintaining tight tolerances across multiple layers can be challenging.

Parting Line Challenges: Stack molds have multiple parting lines, which can complicate the demolding process. Proper parting line design is crucial to avoid issues such as flash or cosmetic defects on the molded parts.

Limited Applicability for Small Runs: Stack molds are most beneficial for high-volume production. For smaller production runs, the increased complexity and cost may not justify the advantages offered by stack molds.

Despite these challenges, stack molds remain a valuable tool in the right applications, particularly when high production volumes and efficiency are paramount. Careful consideration of the specific production requirements and potential challenges is essential when deciding whether to implement stack molds in the tooling industry.

Thank you for your reading!