Application and Analytical Capabilities of Coordinate Measuring Machines in Industrial Sectors

Coordinate Measuring Machines (CMMs) are highly precise measurement devices widely used in the industrial manufacturing sector. By measuring the three-dimensional coordinates of objects, they enable accurate measurements of dimensions, shapes, and positions of components, providing robust support for quality control in the production process.

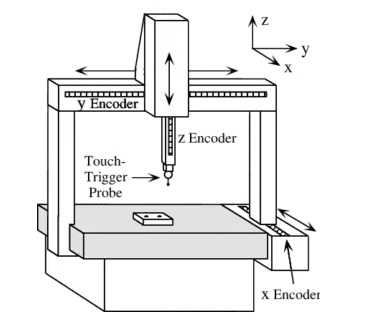

Coordinate Measuring Machine Structure Diagram:

Applications of CMMs in Different Industries:

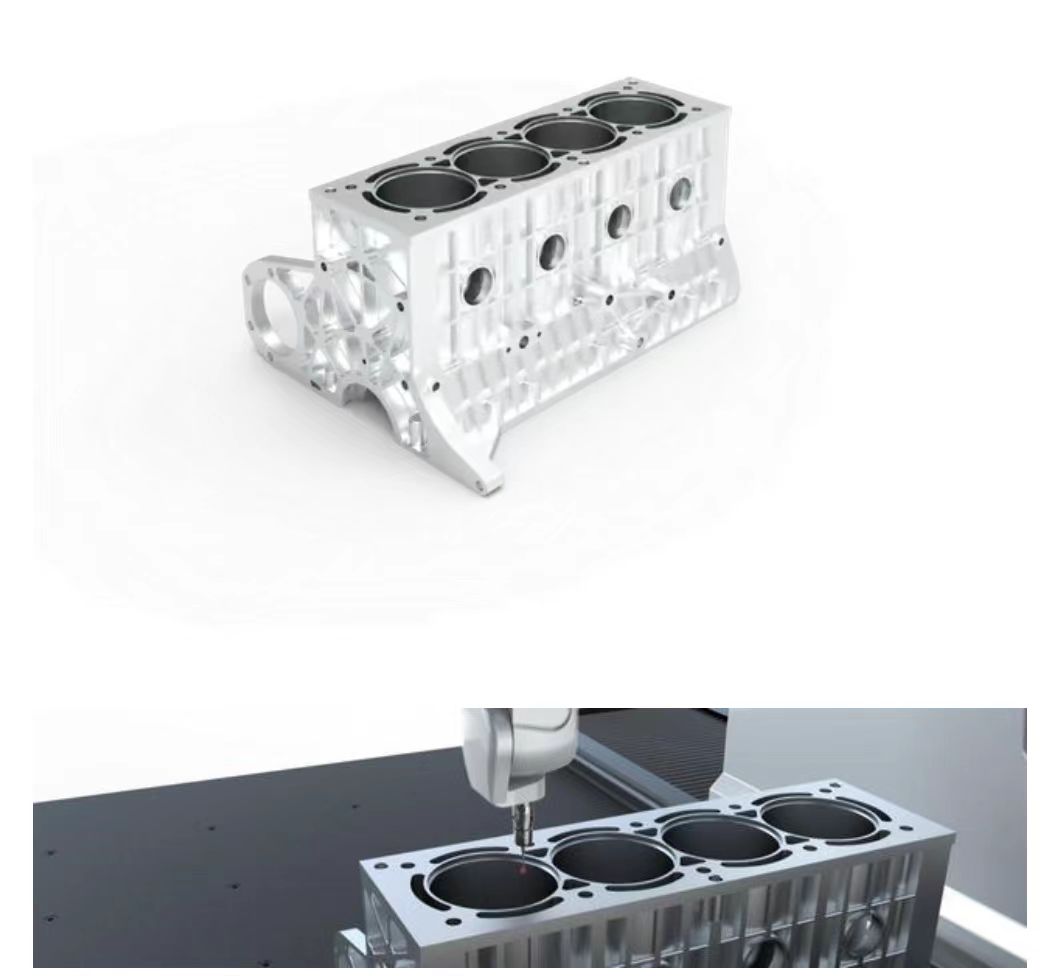

Automotive Manufacturing:

In the automotive manufacturing sector, CMMs play a crucial role in inspecting the dimensions and shapes of components to ensure precise assembly of various automobile parts. By employing CMMs, automotive manufacturers can achieve high-precision measurements of critical components such as engines and body structures, enhancing overall vehicle quality and performance.

Aerospace Industry:

Precision and quality of components are paramount in the aerospace industry for ensuring aircraft safety. CMMs are utilized to measure dimensions and shapes of critical aircraft engine components and wing structures, ensuring precision and interchangeability. This contributes to improving the overall performance of aircraft and ensuring reliability and safety during flight.

Electronics Manufacturing:

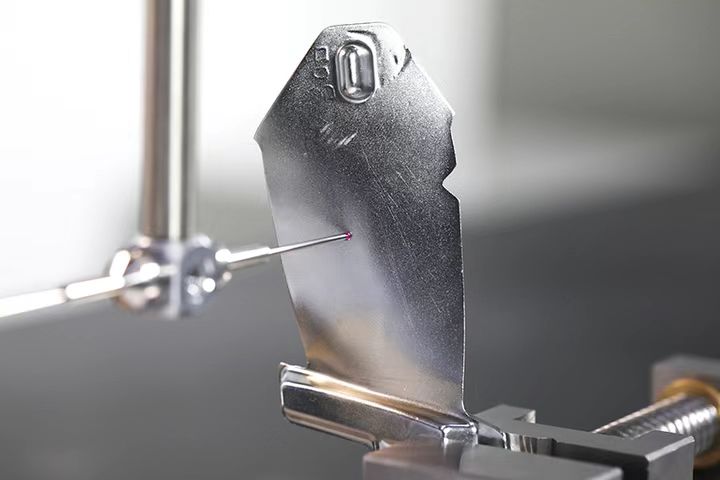

In the electronics manufacturing sector, CMMs are employed to measure the dimensions and positions of electronic components, ensuring the accurate assembly and reliability of electronic devices. For instance, in semiconductor manufacturing, high-precision measurements of tiny components are essential to guarantee the proper functioning of chips. The application of CMMs contributes to enhancing the quality and performance of electronic products.

Analytical Capabilities of CMMs:

Three-dimensional Machine Analysis Capability typically refers to a machine's ability to analyze and process data in three-dimensional space. This capability holds significance across various fields, including computer vision, robotics, virtual reality, and industrial manufacturing.

Three-Dimensional Image Processing and Analysis:

CMMs enable machines to comprehend and process three-dimensional images, widely applicable in medical imaging, geological exploration, and computer-aided design. For example, in the medical field, three-dimensional medical imaging allows machines to reconstruct and analyze three-dimensional organ structures, assisting doctors in accurate diagnosis and surgical planning.

Industrial Manufacturing and Quality Control:

In industrial manufacturing, the analytical capability of CMMs is utilized to measure and verify the three-dimensional geometric shapes of products, ensuring production accuracy and quality. Automated three-dimensional inspection systems efficiently examine the dimensions and shapes of components, elevating the level of quality control in the manufacturing process.

Benefits of Using Coordinate Measurement:

1.High Precision:CMMs boast extremely high measurement accuracy, meeting the stringent precision requirements of various industries.

2.Efficiency:Compared to traditional measurement methods, CMMs enable rapid and automated measurements, enhancing production efficiency.

3.Versatility:CMMs can be used to measure components of various shapes and sizes, showcasing strong applicability.

4.Data Visualization:Measurement data obtained through CMMs can be presented graphically, facilitating engineers and production personnel in understanding and analyzing the data.

Coordinate Measuring Machines play an irreplaceable role in the industrial sector, providing high-precision and efficient measurement solutions for manufacturing. Their wide-ranging applications include automotive manufacturing, aerospace, and electronics industries, offering robust support for quality control and product development. As technology continues to advance, it is anticipated that CMMs will find even broader applications and witness further technological developments in the future