Why MSDS is Critical for the Tooling Mold and Plastics Industry

In the world of manufacturing, safety and compliance are paramount. One of the most important documents ensuring this safety is the Material Safety Data Sheet (MSDS). For companies working in the tooling mold and plastics industry, the MSDS plays a crucial role in maintaining safe and efficient operations. Here's why:

1. Ensuring Worker Safety

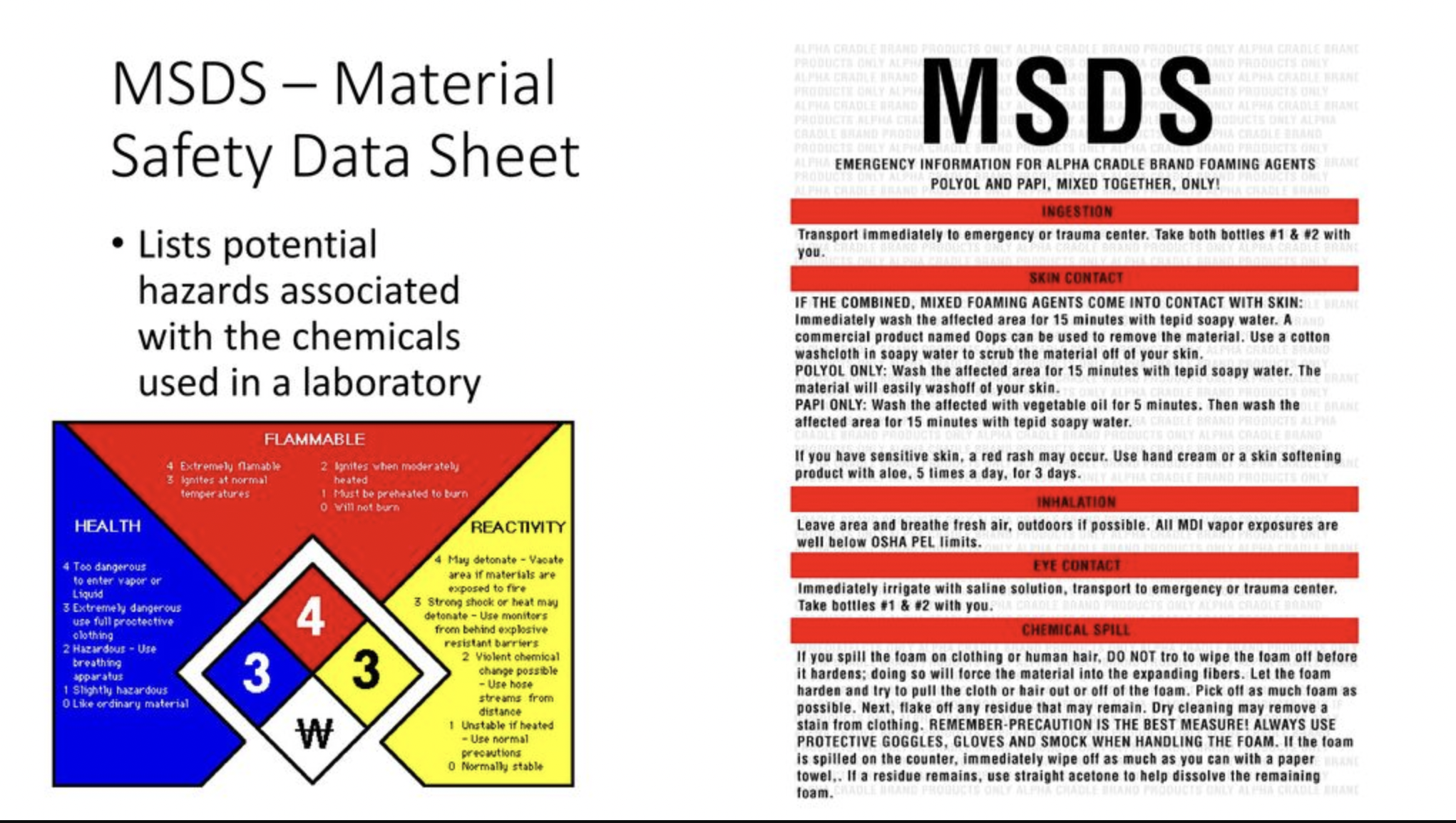

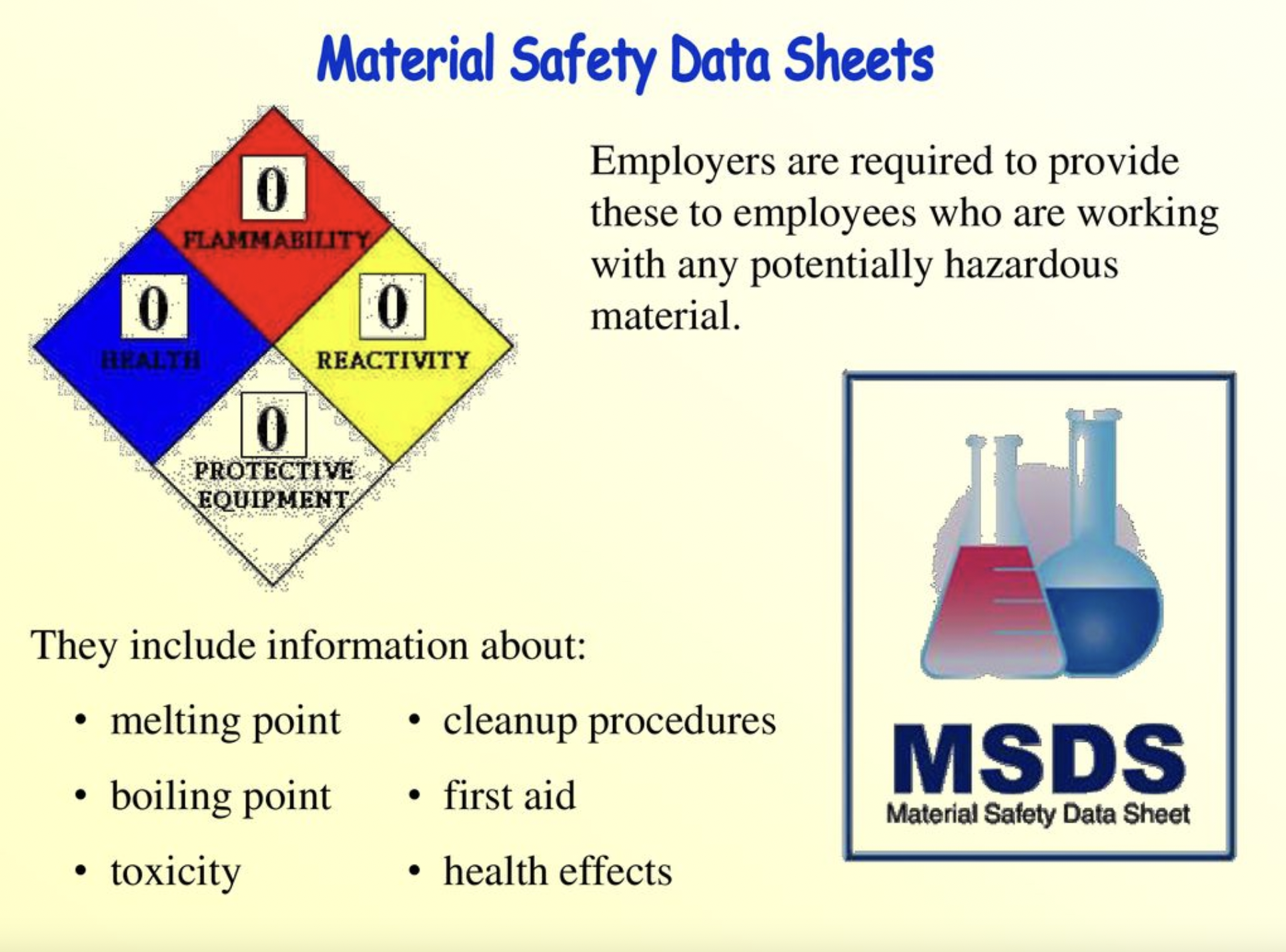

Every material or chemical used in the manufacturing process—whether it’s an anti-rust oil, coolant, or plastic—comes with its own set of risks. The MSDS provides detailed information about potential hazards and the necessary precautions to prevent injuries or accidents. From protective equipment to first-aid measures, the MSDS ensures that workers are fully informed on how to handle materials safely.

2. Compliance with Regulations

For businesses that serve international markets, particularly in Europe, compliance with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) is essential. The MSDS serves as proof that materials meet regulatory requirements. This is especially important when dealing with clients who require materials to conform to environmental and safety standards.

3. Product Quality and Consistency

Using materials with a clearly defined MSDS guarantees consistency in the manufacturing process. This ensures that the parts and products produced meet industry and client specifications. Whether it’s the plastics used for injection molding or protective oils for metal parts, knowing the exact properties of these materials helps maintain high production standards.

4. Fire and Hazard Response

Manufacturing environments involve the use of chemicals that can be flammable or hazardous. The MSDS outlines the specific measures to take in case of emergencies, such as chemical spills or fires. Having these protocols readily available helps mitigate risks and ensures a quick, effective response when needed.

5. Environmental Sustainability

The MSDS provides important information on the environmental impact of chemicals and how to safely dispose of them. As businesses around the globe become more environmentally conscious, adhering to sustainable practices is more important than ever. With an MSDS, companies can ensure they are following proper waste disposal and environmental safety practices.

In the tooling mold and plastics industry, safety, regulatory compliance, and product reliability are non-negotiable. Having an up-to-date MSDS for every material used in the manufacturing process is essential for ensuring safety, building client trust, and maintaining compliance with industry regulations. As a company that values safety and quality, we make sure to carefully evaluate and document the materials we use to meet the highest industry standards.