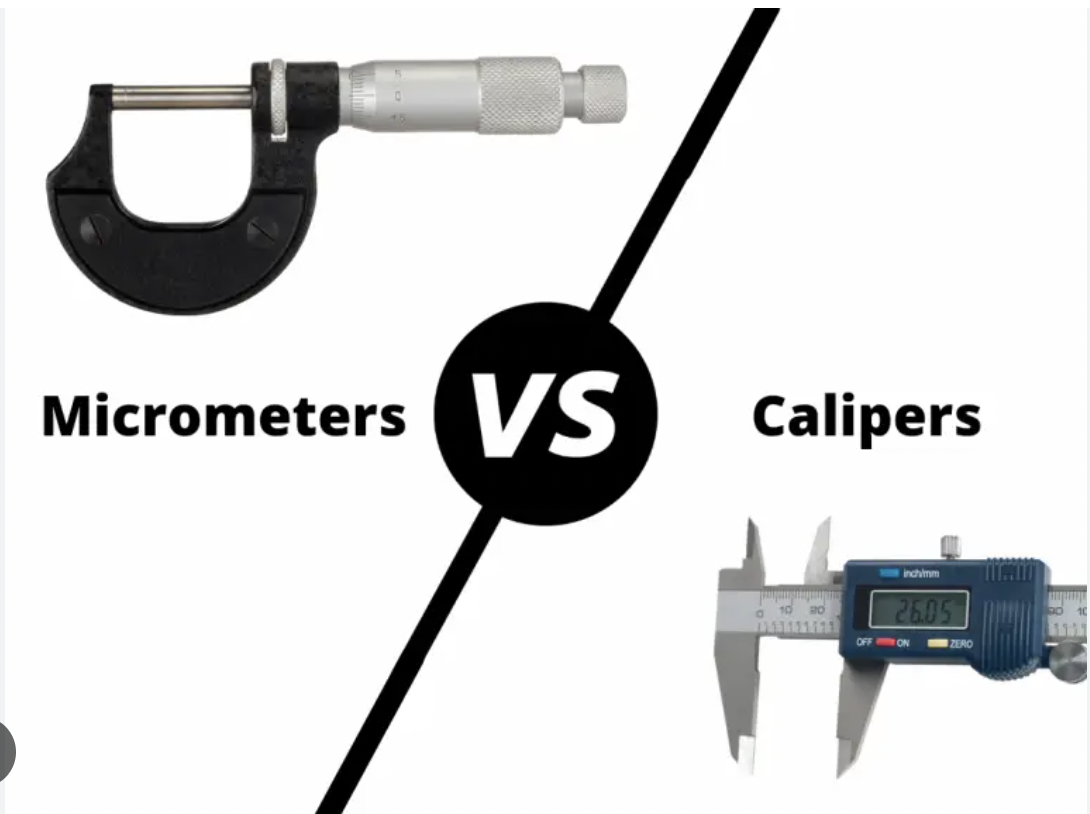

Why micrometers better than calipers?

Hello Everyone, this is Dan.

For more information about me, please visit our website's ABOUT page.

Recently, we shipped some stainless steel CNC machining products to our clients, but unfortunately, the quality was rejected. After conducting a comprehensive meeting with our entire production team, we realized that when it comes to measuring the dimensions of cylindrical objects with higher precision, using calipers may not be the best approach.

As a result, we found it necessary to manufacture the entire batch for the client. Fortunately, the quantity involved is not substantial.

We've summarized why micrometers can be a better choice than calipers in such cases. For further details and information, please don't hesitate to contact me at danny@opro-tech.com.

Micrometers and calipers serve different purposes, and one is not inherently better than the other; it depends on the specific measurement requirements. However, micrometers are often preferred over calipers in certain situations for the following reasons:

Higher Precision: Micrometers typically offer greater precision compared to calipers. They can measure to the nearest thousandth of a millimeter (0.001 mm or 1 micron), whereas calipers are generally accurate to the nearest hundredth of a millimeter (0.01 mm or 10 microns).

Outside Diameter Measurement: Micrometers excel in measuring the outer dimensions of cylindrical objects. They are commonly used for measuring the diameter of shafts, rods, and other cylindrical components where high precision is critical.

Depth Measurement: Some micrometers, like depth micrometers, are specifically designed for measuring the depth of holes, slots, or other recessed features. Calipers are less suited for such measurements.

Flatness and Parallelism: Micrometers are better for measuring flatness and parallelism, especially when assessing the thickness of precision components like gaskets and shims.

Consistency: Micrometers tend to provide more consistent and repeatable measurements, which is essential in manufacturing and quality control processes.

Reduced Parallax Error: Micrometers have a spindle and anvil that come into direct contact with the measured surface, reducing the risk of parallax errors that can occur with calipers.

However, it's essential to note that calipers have their advantages as well. They are generally quicker and easier to use for measuring external dimensions and are versatile for a wide range of applications. The choice between micrometers and calipers should be based on the specific measurement needs, precision requirements, and the type of objects being measured. In many cases, a combination of both tools is used to ensure accurate measurements in various scenarios.

Thanks for your reading, and wish you good luck in CNC machining production.

danny@opro-tech.com

www.opro-tech.com