What is the difference between single cavity and multi cavity mold?

What is the difference between single cavity and multi cavity mold?

Single cavity and multi-cavity molds are two common types of molds used in manufacturing processes, particularly in injection molding. The primary difference between them is the number of identical parts or components they can produce in a single cycle. Here's a breakdown of the differences:

Single Cavity Mold:

Single cavity molds, as the name suggests, have only one cavity or void where the material (usually plastic) is injected to create a single part or component.

They are used for producing a single piece of the desired product in each mold cycle.

Ideal for small production runs or when each part requires special attention or customization.

Generally, single cavity molds are simpler in design and less expensive to create and maintain compared to multi-cavity molds.

Multi-Cavity Mold:

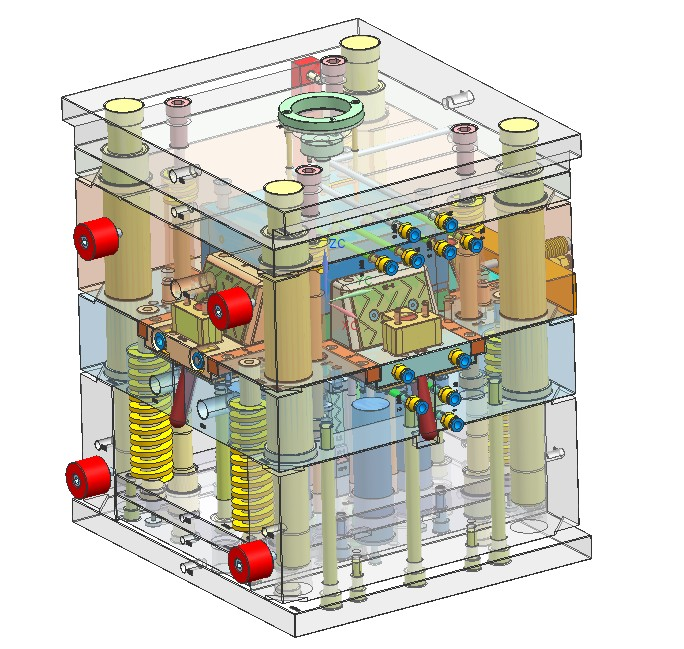

Multi-cavity molds have multiple cavities within a single mold. These cavities can be identical and produce the same part or can be designed for producing different parts simultaneously.

They are used for higher volume production, as they can produce multiple parts in a single mold cycle.

Suitable for mass production and high-efficiency manufacturing processes.

Multi-cavity molds are more complex in design and require more precise machining, which can make them more expensive to produce and maintain. However, the cost per part is generally lower in high-volume production.

In summary, the main difference is that a single cavity mold produces one part per cycle, while a multi-cavity mold can produce multiple identical parts (or different parts) in a single cycle. The choice between the two depends on the required production volume, cost considerations, and the complexity of the parts being produced.

For more information about your projects please contact danny@opro-tech.com