Are plastic injection molds expensive?

The cost of plastic injection molds can vary significantly depending on several factors, making it challenging to provide a precise answer about their expense. Some key factors that influence the cost of plastic injection molds include:

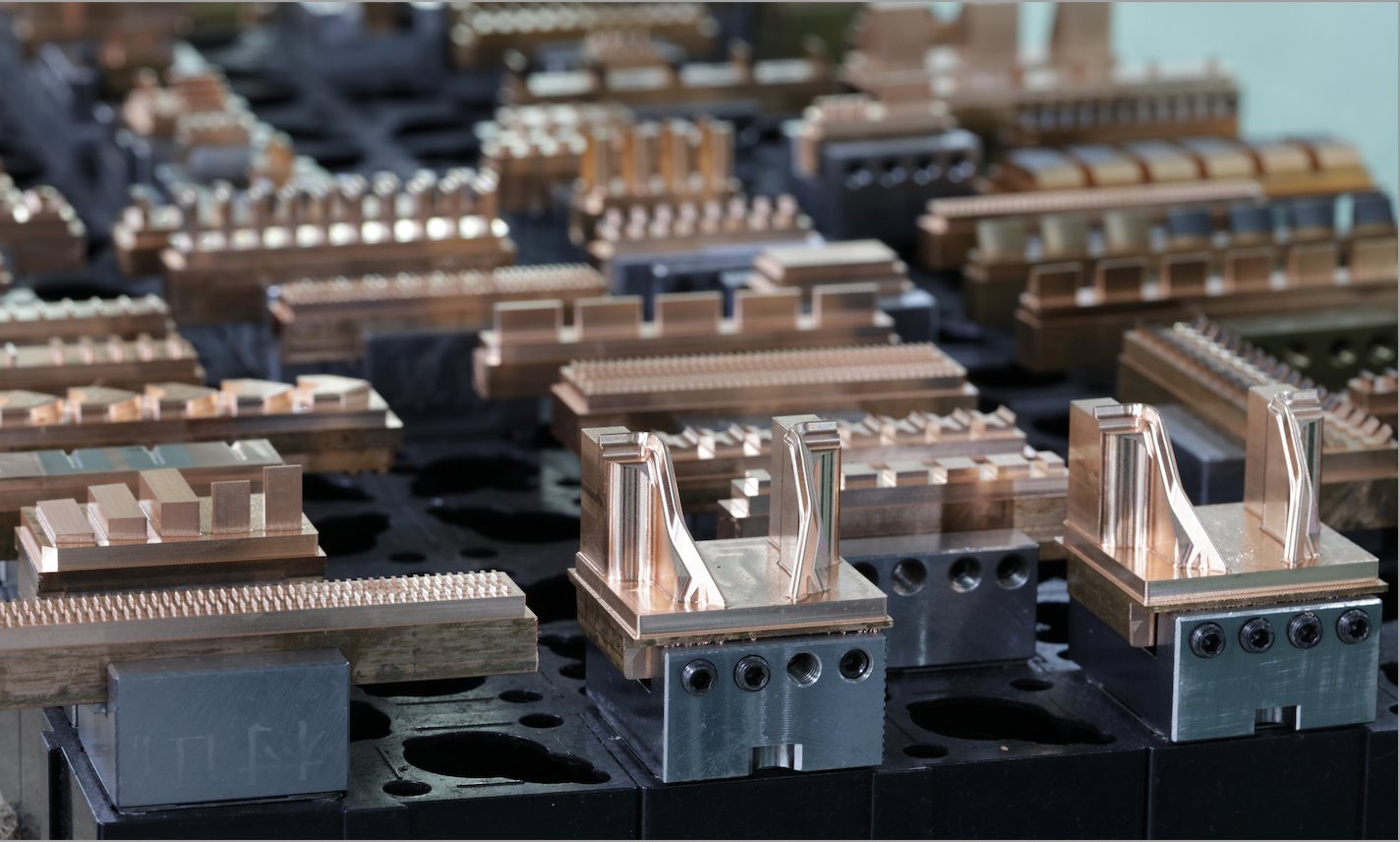

Part Complexity: The complexity of the part being produced is a primary factor. More complex parts with intricate shapes, undercuts, or fine details often require more complex molds, which can be more expensive.

Material Choice: The type of plastic material used also plays a role. Some materials require special considerations and tooling, which can increase mold costs.

Tolerance and Surface Finish: Tight tolerances and specific surface finishes can affect mold complexity and consequently cost.

Mold Size: Larger molds, required for bigger parts, typically cost more than smaller molds.

Quantity: The number of parts to be produced affects the cost. For high-volume production, the mold's cost can be spread across many units, reducing the per-part cost.

Tooling Materials: The type of materials used to construct the mold, such as steel or aluminum, can significantly impact the cost.

Mold Features: Additional features like slides, lifters, or multiple cavities will add to the mold's cost.

Lead Time: Fast-track or expedited mold production often comes at a premium.

Given these variables, it's important to work closely with a mold designer and manufacturer to get a precise cost estimate tailored to your specific project. Plastic injection molds can be a significant upfront investment, but they are often cost-effective for high-volume production because they can produce large quantities of parts with high precision and consistency.

If you want to make your own tooling mold for what every plastic parts, we can help you from the beginning, just give us your idea and we can make it.

Contact us: 86 134 1699 5669

Whatsapp: +86 134 1699 5669

Email : danny@orpo-tech.com

Https: www.opro-tech.com