What is edge gate and pin point gate, what are their differences and advantages?

The gate is the link between the part and the runner system. I’m Dan from Opro-tech engineering, in this summary I’m sharing something that I learned about edge gate and pin-point gate.

An edge gate and a pin-point gate are both types of gates used in injection molding, each with its own characteristics and applications.

Edge Gate:

Location: An edge gate is typically located at the edge of the part, where the molten plastic enters the cavity.

Shape: It is characterized by a thin, rectangular opening through which the material is injected.

Advantages:

It provides a good aesthetic finish on the part since the gate is often placed at a less visible location. It allows for easy removal of the gate vestige or scar after molding. Well-suited for flat parts.

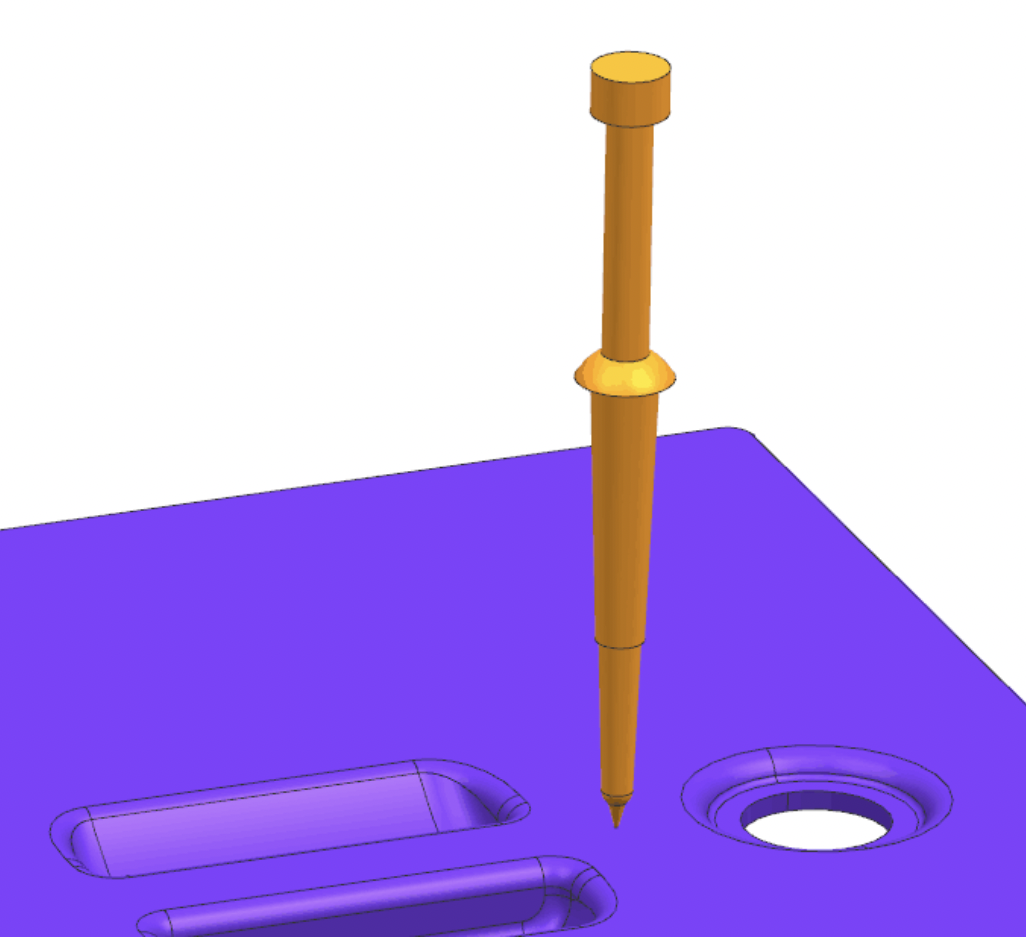

Pin-Point Gate:

Location: A pin-point gate is a small, circular gate usually located on the part's surface.

Shape: It has a small diameter and forms a circular mark on the molded part.

Advantages:

It is suitable for parts where cosmetic appearance is less critical. Often used in parts where the gate vestige is acceptable, and no additional finishing is required. Effective for gating in tight spaces or small parts.

Differences between the two gates:

Appearance: The main difference lies in the appearance of the gate vestige on the molded part. Edge gates tend to leave a thin, rectangular mark, while pin-point gates leave a small, circular mark.

Cosmetic Considerations: Edge gates are preferred when cosmetic appearance is crucial, as they offer better aesthetics. Pin-point gates are chosen when the appearance of the gate mark is less critical.

Gate Removal:

Edge gates are easier to remove since they leave a thin vestige. Pin-point gates may require less post-processing but can leave a more visible mark.

The choice between edge gate and pin-point gate depends on factors like part design, cosmetic requirements, and the specific characteristics of the molded product.

Thank you for taking the time to read my message. I work as a salesperson in a tooling mold and CNC machining factory, and I'm committed to enhancing my technical knowledge in this field.

The mold and machining industry is undergoing rapid evolution, marked by constant innovation and technological breakthroughs. If you notice any inaccuracies or have valuable insights to share, please feel free to reach out to me at danny@opro-tech.com. I am eager to learn from your expertise. Thanks.