What is valve gate in injection tooling molds?

🤗 Hello again! As I continue my exploration of the intricacies of part design, molds, and the molding industry, I'm continually fascinated by the entire process. 😘

Today, I stumbled upon some intriguing insights into #valvegates, adding another layer of interest to my learning journey. Below, I'm excited to share some of the key points from my #studynotes . 🤔

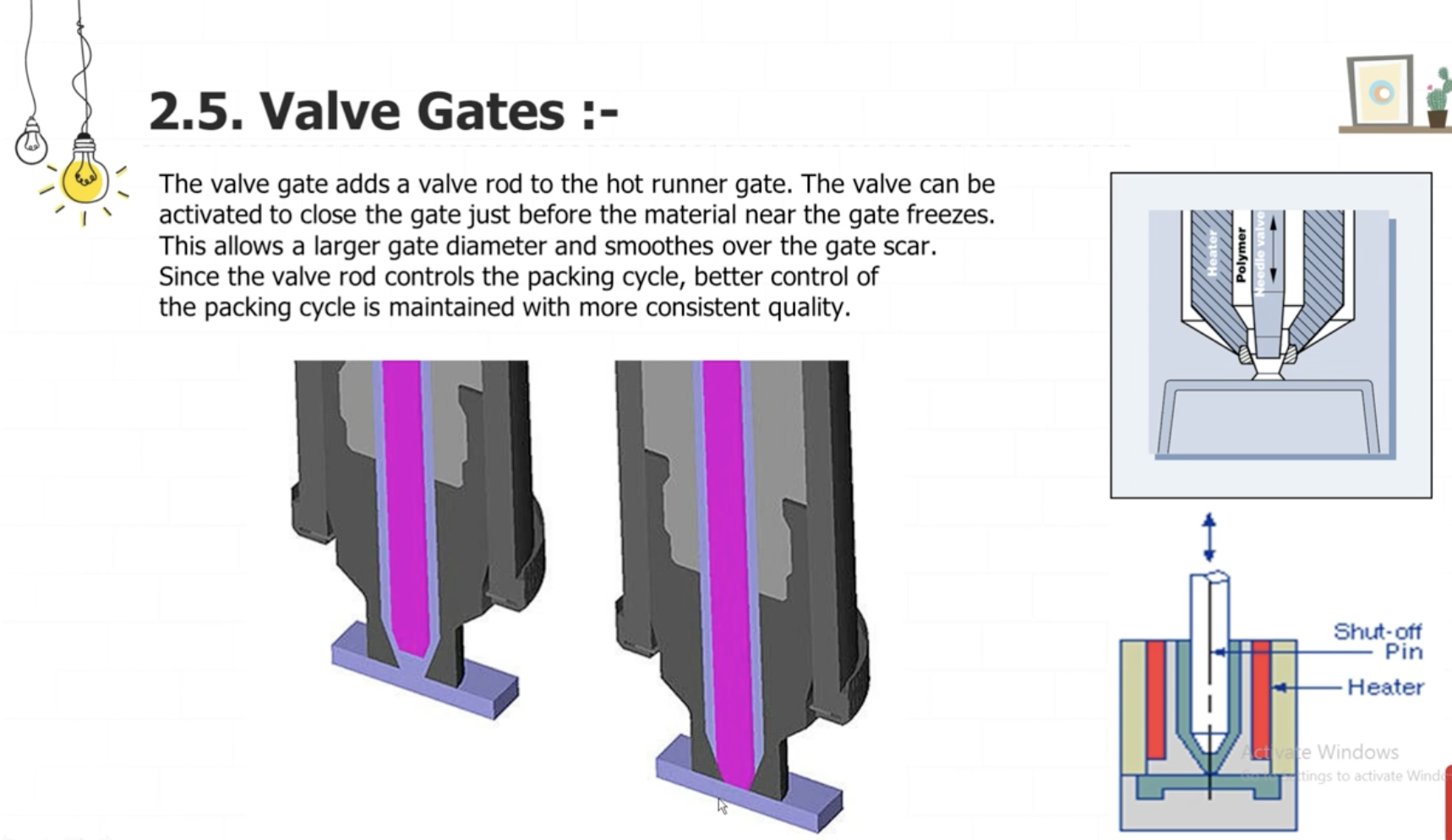

👩 A valve gate in #injectionmolds is a type of gating system that uses a mechanical valve rod to control the flow of molten #plastic into the mold cavity.

It is a sophisticated and precise method that allows for more control over the #injectionmolding process. The valve gate system is located at the #gatepoint, which is the entry point for the molten plastic into the #mold . 👩💻

Here's how the valve gate system works 👩💻 :

#InjectionPhase: During the injection phase of the #molding cycle, the valve gate is closed. This means that the flow of molten plastic is blocked at the gate, preventing it from entering the mold cavity. 📣

#Accumulation of Pressure: As the plastic material accumulates in front of the closed valve gate, pressure builds up. 🔔

Valve Opening: Once a sufficient amount of molten plastic has accumulated, the valve gate opens precisely and rapidly. This controlled opening allows the molten plastic to flow into the mold cavity. 🔎

#mold Filling: With the valve gate open, the molten plastic fills the mold cavity, taking the shape of the desired part. 🔎

Valve Closure: After the mold is filled, the valve gate quickly closes to prevent any additional plastic from entering the mold.

✅ ❓ The use of a valve gate provides several advantages:

🔰 Reduced Gate Vestige: Valve gating minimizes the vestige, or mark, left on the molded part at the gate location. This is especially crucial for parts with stringent #cosmeticrequirements.

🔆 Precise Control: The valve gate allows for #precise control over the flow of plastic into the mold cavity, resulting in better part quality.

♻ Minimized Shear Stress: The controlled opening and closing of the valve gate help minimize shear stress on the plastic material, reducing the likelihood of material degradation.

🔗 Less Gate Flash: Valve gating can help reduce gate flash, which is excess material that can occur at the gate area.

⚙ Valve gate systems are often used in applications where #highprecision , #cosmeticappearance, and consistent part quality are critical. They are commonly found in the production of complex and high-value plastic parts.

📡 Thank you for being part of this exciting learning experience.

If you notice anything that needs correction or have valuable insights to share, please feel free to reach me out at danny@opro-tech.com. 😘 👩🔧

Your input is highly valued.

#studynotes #toolingsolutions #injectionmould #moldlearning #toolingdesign #gatetype #plasticinjectionmolds