What is SurTec650?

While organizing today's quotations, I found myself harboring some doubts about the SurTec 650 post-treatment process. Quickly turning to online resources for relevant information, this exploration not only deepened my understanding of the characteristics and applications of SurTec 650 but also offered a more comprehensive perspective on this particular post-treatment technique. In this article, I aim to share the insights gained during my research on SurTec 650 and discuss its potential impact on quotations and the manufacturing process.

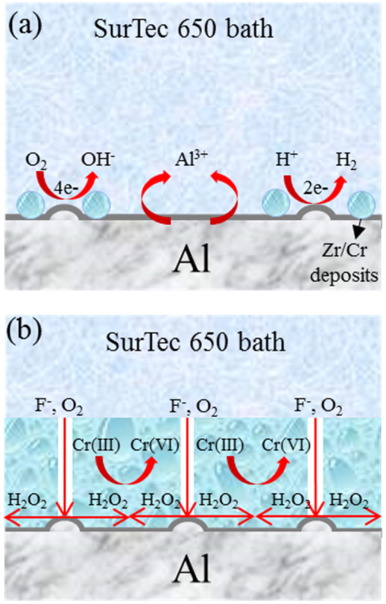

SurTec 650 is a phosphoric acid zincate treatment, ideally suited for coating active metals such as aluminum and magnesium.

The primary functions of SurTec 650 include:

Corrosion Resistance: SurTec 650 forms a protective zinc phosphate film on the metal surface, preventing contact with oxygen and moisture and thereby slowing down or preventing corrosion.

Improved Coating Adhesion: This treatment aids in enhancing the adhesion of coatings to metal surfaces, ensuring a more robust coating.

Surface Pre-treatment: In some cases, SurTec 650 serves as a pre-treatment for surfaces before coating, providing a solid foundation for subsequent coating processes.

Is SurTec 650 Expensive?

Despite the relatively high overall cost of SurTec 650, considering its exceptional coating quality and the manifold benefits it offers, it undoubtedly represents a wise choice for the future.

This product ensures a longer lifespan for metals, reduces friction, and achieves these performance advantages without adding excessive weight. The clean and smooth surface finish it creates is particularly beneficial for delicate aluminum components.

Moreover, the coating layer produced using this product can resist humidity and other environmental damages, keeping metal surfaces corrosion-free and protected against erosion. SurTec 650 not only preserves the chemical composition of metals but also maintains their strength. Even with the addition of this surface coating, it remains lightweight and aesthetically natural. Given these advantages, the higher cost of the product can be viewed as a long-term investment, providing reliable protection and performance optimization for metal components.