What are the benefits of electropolishing machined parts?

When I learned about the post-processing process of electrolytic polishing, I found that polishing can be divided into different types (mechanical polishing, chemical polishing, electrolytic polishing), different types of polishing surface treatments and their advantages and disadvantages. Today I just learned from electrolytic polishing. Share my learning.

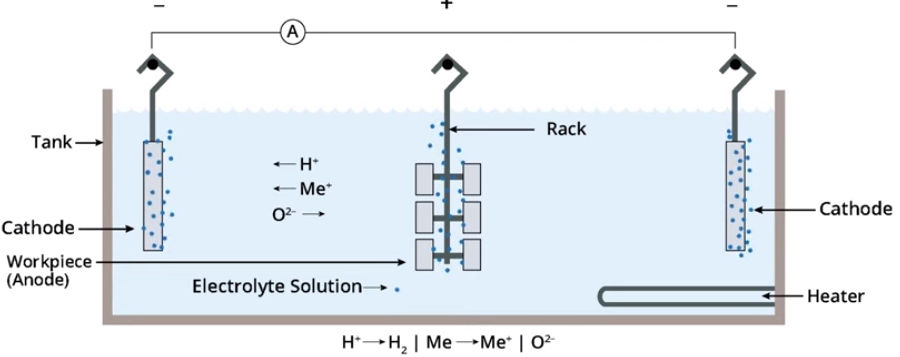

When the surface of the metal workpiece we use is uneven, we can level it through electrolytic polishing. Electrolytic polishing is an electrochemical method of finishing. As long as it is used to treat metal surfaces, it has four major advantages.

1. Electrolytic polishing uses an electrochemical process to smooth the polished surface. Therefore, there will be no deformation layer formed during mechanical polishing on the surface, and there will be no foreign material inclusions.

2. The polished surface has low roughness and strong reflective ability. The thickness of the polished surface is easy to control;

3. It can polish parts with complex geometric shapes (especially suitable for small parts). The polishing speed is fast, the efficiency is high, the operation is convenient, easy to master, and the labor intensity is low.

4. Electroplating of electrolytically polished parts can improve the bonding force between the coating and the substrate, remove the surface oxide layer, rust and other factors that may cause corrosion, thereby improving the corrosion resistance of the product.

But it also has shortcomings

High equipment investment will increase production costs.

Complex pre-polishing process

Tooling and auxiliary electrodes required for complex parts.

Polished Surface Treatment Frequently Asked Questions

What is the main purpose of the polishing process?

Polishing helps create a shiny, smooth surface on custom parts. It helps improve the appearance of parts while preventing corrosion (by removing oxidation), improving cleanability and reducing part adhesion. The polished surface treatment also imparts significant reflective properties to the clean material surface. All of this is designed to ensure the parts meet customer expectations.

What is polish?

Simply put, polishing agent is a reagent that makes the surface of an object bright. The brightness of the polished product is uniform, and the optimal processing temperature of this agent is medium temperature, so there is no need to add too high a temperature.