Why do mold factories purchase mold base from mold base supplier instead of making it themselves?

😂 🤣 For someone new to the world of tooling molds, the concept of a mold base might seem a bit perplexing. Initially, 🤗 I assumed that our workshop would produce the mold base itself – a notion that, as it turns out, is incorrect but quite amusing.

😎 If you're embarking on your journey in the tooling industry, welcome aboard! Let's navigate this learning adventure together.

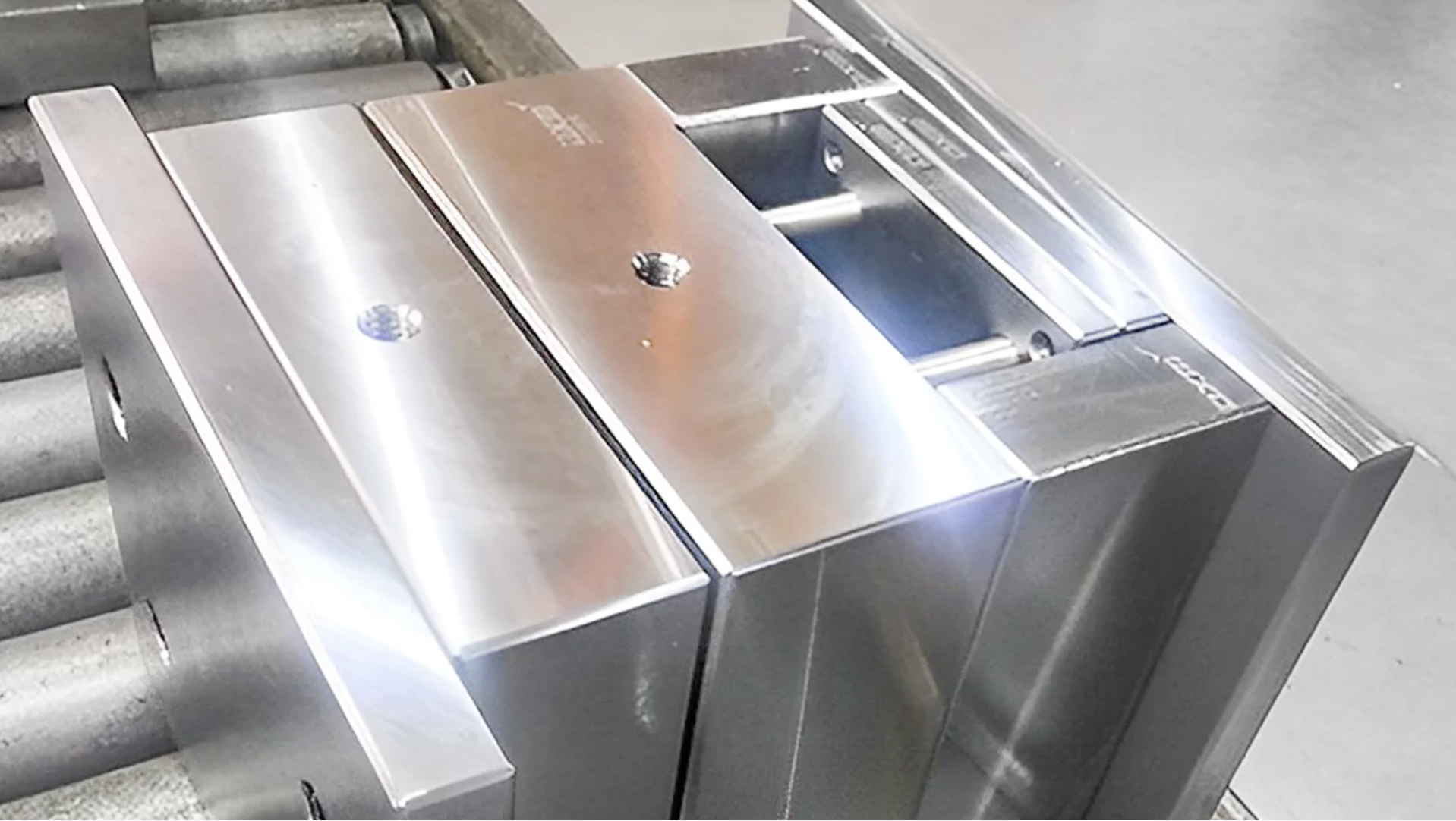

A #moldbase in #tooling refers to the part of a mold that holds the #cavities, cores, and other components necessary for shaping a plastic or metal part through the process of injection molding or other molding techniques.

📣 It serves as the foundation or support structure for the mold components and provides a framework for the molding process.

Mold bases are typically made from materials such as steel or aluminum and are designed to be durable and precise. They come in various standard sizes and configurations, allowing for flexibility in the design and production of different molds.

💹 💹 There are several reasons why mold factories often purchase mold bases instead of making them themselves:

🛡 🛡 Time and Cost Efficiency: Building a mold base from scratch requires significant time, labor, and resources. Purchasing standardized mold bases is a more efficient option, as it eliminates the need for extensive design and machining processes.

🔩 🔩 Standardization: Mold bases are often available in standard sizes and configurations. By using standardized mold bases, manufacturers can achieve consistency and interchangeability between different molds, making it easier to replace components or modify molds for different production needs.

🔆 🔆 Expertise: Mold base manufacturers specialize in producing high-quality, precision mold bases. They have the expertise and equipment necessary to ensure that the mold bases meet the required specifications and tolerances. This specialization allows mold factories to focus on their core competencies, such as designing and producing custom mold inserts or cores.

📈 📈 Cost Savings: Purchasing standardized mold bases in bulk can lead to cost savings due to economies of scale. Mold base manufacturers can produce these components in large quantities, reducing per-unit costs compared to in-house production.

📉 📉 Reduced Lead Time: Buying mold bases can significantly reduce the lead time for mold production. Mold bases are readily available in the market, and factories can start building custom molds more quickly by using pre-made bases.

✅ 🔰 Quality Assurance: Reputable mold base suppliers often have quality control processes in place to ensure that the bases meet industry standards. This can help mold factories maintain consistent quality in their molds.

In summary, #moldfactories purchase mold bases instead of making them themselves because it is a more efficient, cost-effective, and reliable option. It allows them to focus on their core competencies, reduce lead times, and benefit from standardized components