What is salt bath nitriding

When I try to understand the salt bath nitriding process by watching videos, I often come across comparisons between nitriding and carburizing, which leaves me somewhat confused.

This is the explanation I found on Google about salt bath nitriding.

Salt bath nitriding is a surface treatment technique primarily used to enhance the hardness and wear resistance of metal components. This process, commonly known as nitriding heat treatment, involves introducing nitrogen atoms to the metal surface, forming a hard nitrided layer to improve material performance. In salt bath nitriding, a salt bath is typically used as the nitrogen source and heating medium.

By the way, I was thinking, since nitriding is a heat treatment, are there other ways of cold treatment?

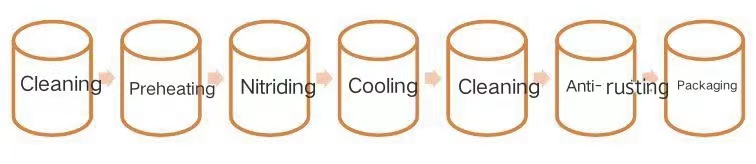

Here's the process of salt bath nitriding that I summarized after watching the video.

I'm not sure if my summary is accurate, and I'd like to hear your thoughts:

Of course, all post-treatment processes have advantages and disadvantages:

Advantages:

Increased Hardness: Salt bath nitriding significantly improves the hardness of metal components, making them suitable for high-wear and high-load environments.

Enhanced Wear Resistance: The formed nitrided layer not only increases hardness but also improves the wear resistance of components, extending their lifespan.

Improved Corrosion Resistance: The nitrided layer enhances the corrosion resistance of metal components, making them more durable.

Applicable to Complex Shapes: Salt bath nitriding is suitable for various shapes and sizes of metal components, including complex geometries, providing flexibility for diverse applications.

Applicable to Various Metals: Salt bath nitriding can be applied to different types of metals, such as steel, iron, stainless steel, and more.

Disadvantages:

High Processing Temperature: Salt bath nitriding typically requires high processing temperatures, which may lead to deformation or thermal stress in some materials, requiring additional heat treatment steps to mitigate these effects.

Long Processing Time: The nitriding process may require a considerable amount of time, especially when quenching of parts is involved, potentially increasing the production cycle.

High Cost: Equipment and material costs for salt bath nitriding are relatively high, making this treatment method less economical in budget-constrained situations.

Additionally, when I searched on Google, I found some people asking about the appearance of black spots on products after salt bath nitriding. I couldn't find the answer I was looking for on Google, so if anyone knows, could you please explain why this happens?