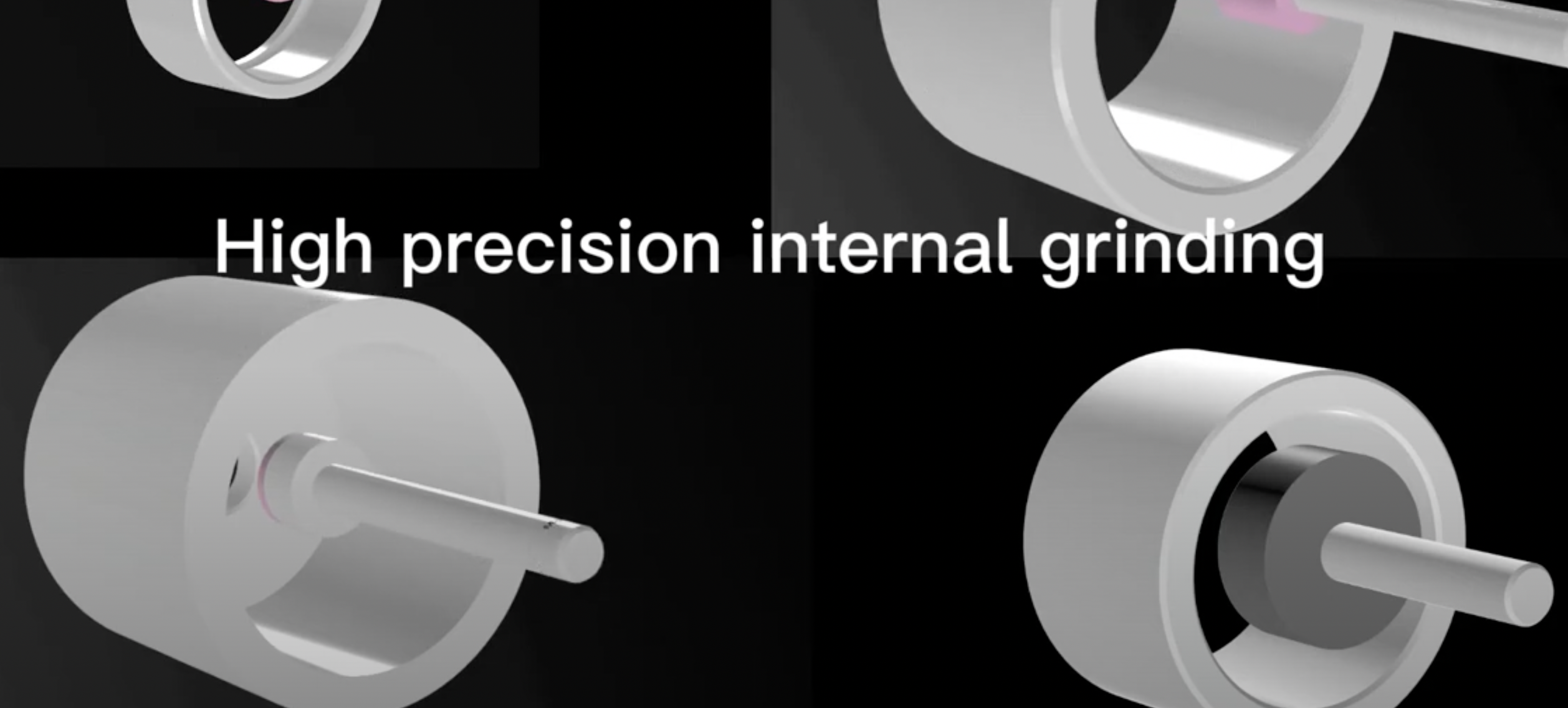

How to do internal grinding?

💁♀️ 💁♀️ Regarding this product, upon reviewing the drawing, I noticed that the client specifies an inner #roughnessrequirement of 0.8. Typically, we are accustomed to dealing with #surfaceroughness.

❤️ The material is #Brass 2.0401

❤️ z: 88,00mm d: 15,00mm

❤️ #Tolerance: DIN ISO 2768 – mH

❤️ #Innerroughness: 0.8

🛡 🛡 #Innerpolishing for #CNCmachined #brasstubes involves several steps to achieve a smooth and polished surface on the interior of the tube. Here is a general guide on how to perform inner polishing for CNC machined brass tubes:

✅ Select the Right Tools and Materials:

Choose appropriate polishing tools such as abrasive stones, abrasive brushes, or specialized polishing brushes. What we use to do the #polishing is called #punchingmachine.

✅ Cleaning the Tube:

Before polishing, ensure that the inner surface of the brass tube is thoroughly cleaned. Remove any debris, oils, or machining residues.

✅ Initial Coarse Polishing:

Use coarse abrasive tools to remove any machining marks or rough surfaces. This step helps to prepare the surface for finer polishing.

✅ Intermediate Polishing:

Progress to finer abrasive tools or brushes to achieve a smoother surface. This step helps in refining the surface and reducing any scratches left from the coarse polishing.

✅ Fine Polishing:

Use fine abrasive tools or specialized polishing brushes to further refine the inner surface. This step is crucial for achieving a high-quality, smooth finish.

✅ Inspecting the Surface:

Regularly inspect the inner surface of the #brass tube during the polishing process to ensure uniformity and the desired level of smoothness.

✅ Final Polishing:

Perform a final polishing step using a fine abrasive compound or polishing solution to achieve the desired level of gloss and smoothness.

✅ Cleaning After Polishing:

Thoroughly clean the inner surface of the tube to remove any polishing residues.

✅ Quality Inspection:

Inspect the polished inner surface for any defects, scratches, or irregularities. Ensure that the specified dimensional requirements are met.

Surface Protection:

🔰 📁 It's important to note that the specific process may vary based on the design, size, and intricacy of the brass tube. Additionally, the selection of polishing tools and compounds should be based on the specific requirements of the project and the desired finish.

👩💻 Always follow safety guidelines and wear appropriate personal protective equipment when performing polishing operations.