What is the most important thing for support plate in a tooling mold?

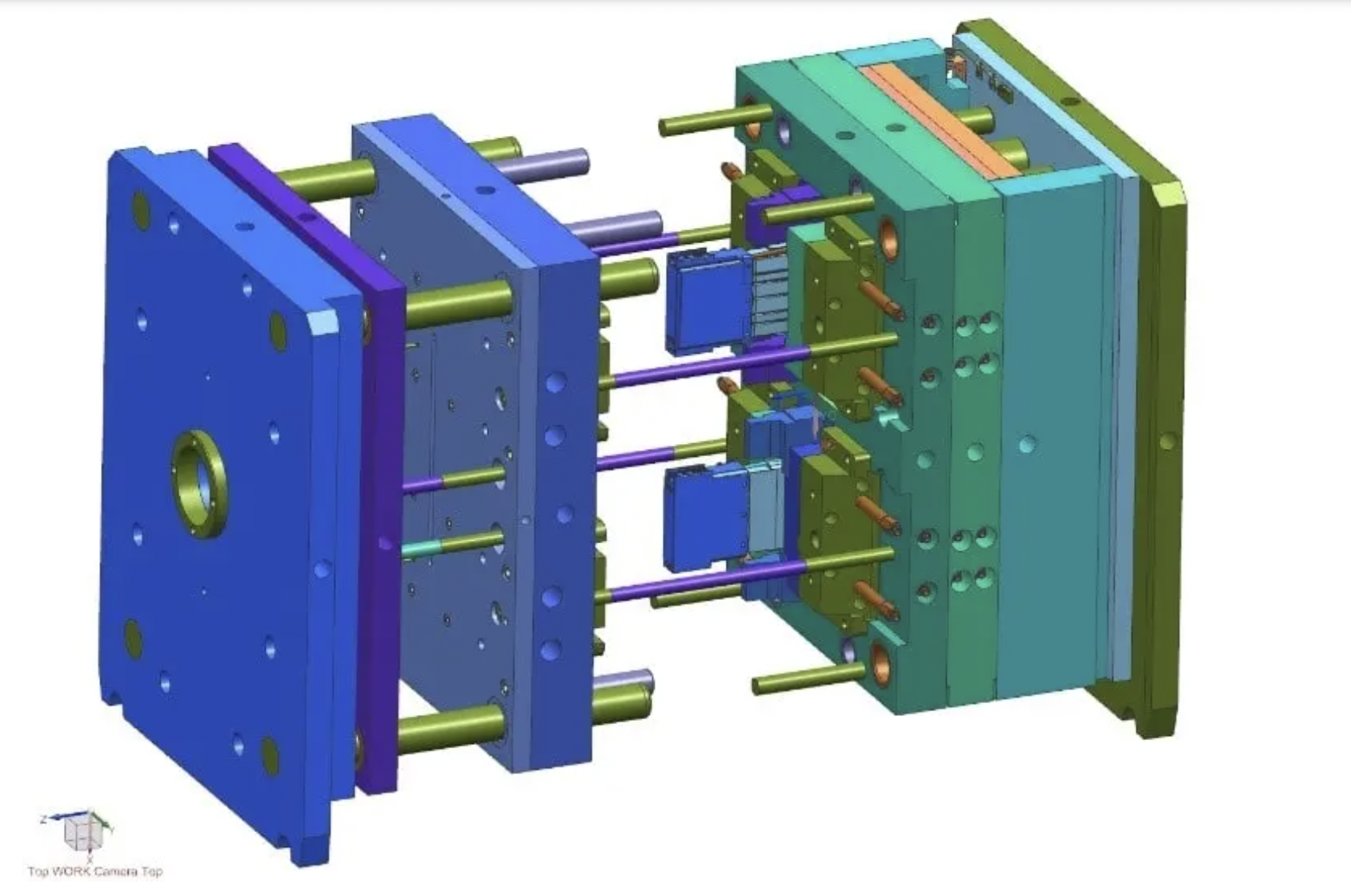

😊 I recently dived into the significance of #supportplates in #tooling molds, the reason to have a support plate demonstrate below. 👩🏫

🤔 🤔 It appears that having a support plate not only enhances structural integrity but also proves instrumental in mitigating #machiningcosts, particularly for the B plate. The absence of a support plate may elevate both raw material costs and machining time for the #Bplate.

⛔ This revelation has sparked a question in my mind. Typically, support plates accompany the B plate, but in instances involving #intricateparts, should we also consider incorporating a support plate for the A plate? ❗ ❓

🤗 🤗 Thank you for your sharing and I’m so looking forward to hearing from you at danny@opro-tech.com . Thanks.

👩🔧 👩🔧 A support plate in tooling #molds serves as a structural #component that provides additional reinforcement and support to the mold structure. It is typically a flat plate positioned within the #moldassembly to enhance rigidity and stability.

👩💻 The primary functions of a support plate in tooling molds include:

📣 Enhanced Structural Integrity:

🔎 Support plates are strategically placed to reinforce critical areas of the mold, preventing deformation or distortion during the #injection #molding process. This is particularly important in molds handling high pressures and stresses.

📣 Distribution of Load:

👋 Support plates help distribute the load evenly across the mold, reducing localized stress points. This is crucial for maintaining the #dimensional accuracy of the molded parts and extending the lifespan of the mold.

📣 Prevention of Warping:

In molds with larger dimensions or intricate shapes, support plates play a key role in minimizing the risk of warping or bending. They contribute to maintaining the flatness and stability of the #moldsurfaces.

📣 Alignment and Registration:

Support plates aid in aligning mold components accurately. They ensure proper registration of moving and stationary mold halves, contributing to #precise and consistent #partproduction.

📣 Heat Dissipation:

Support plates may also assist in the dissipation of heat generated during the molding process. Proper heat management is essential to control temperature variations within the mold and achieve uniform cooling of the molded parts.

💕 The design and placement of support plates depend on the specific requirements of the mold and the characteristics of the molded parts. They are often made from high-strength #materials to withstand the #mechanical forces encountered during the #injectionmoldingcycle.

📖 📖 In summary, a support plate in tooling molds is a critical element that reinforces the mold structure, distributes loads, prevents deformation, and contributes to the overall stability and performance of the mold during the manufacturing process.

#toolingstudy #toolinglearning #toolingmold #moldmaker #moldfactory

In the end, I wanted to bring to your attention that I utilized a screenshot from Google for the picture in my recent communication. If there are any copyright concerns associated with the image, kindly reach out to me at your earliest convenience, and I will promptly address the matter by removing the image. Thanks again.