Why are hot runners controlled by some renowned companies globally

Hi, it's me again 😘 . After learning some information about different gate types and their advantages, I've now dived into the world of hashtaghotrunners. It's always fascinating to learn something new 😍 .

I have a few questions about this 😇 😇 :

👩💻 1, Why are hot runners controlled by some renowned companies globally, such as hashtagYUDO, hashtagMOLDMASTERS, D-M-E, and hashtagINCOE? How do they maintain such high-quality systems?

👩💻 2, Why is the hot runner system typically manufactured by specialized hot runner system companies rather than the tooling molds factory?

It might sound like a simple or silly question 🤦♀️ but these are my curiosities. I would appreciate hearing your insights on hot runners, please share to danny@opro-tech.com or leave a comment below. 👇

My study notes for your reference.

👏 A hot runner system is a technology used in injection molding to convey molten plastic from the machine nozzle to multiple cavities of a mold. The primary advantage of a hot runner system is that it eliminates the need for a sprue and runner system, reducing material waste and improving cycle times. The plastic remains molten in the hot runner, allowing for more efficient and precise injection into the mold cavities.

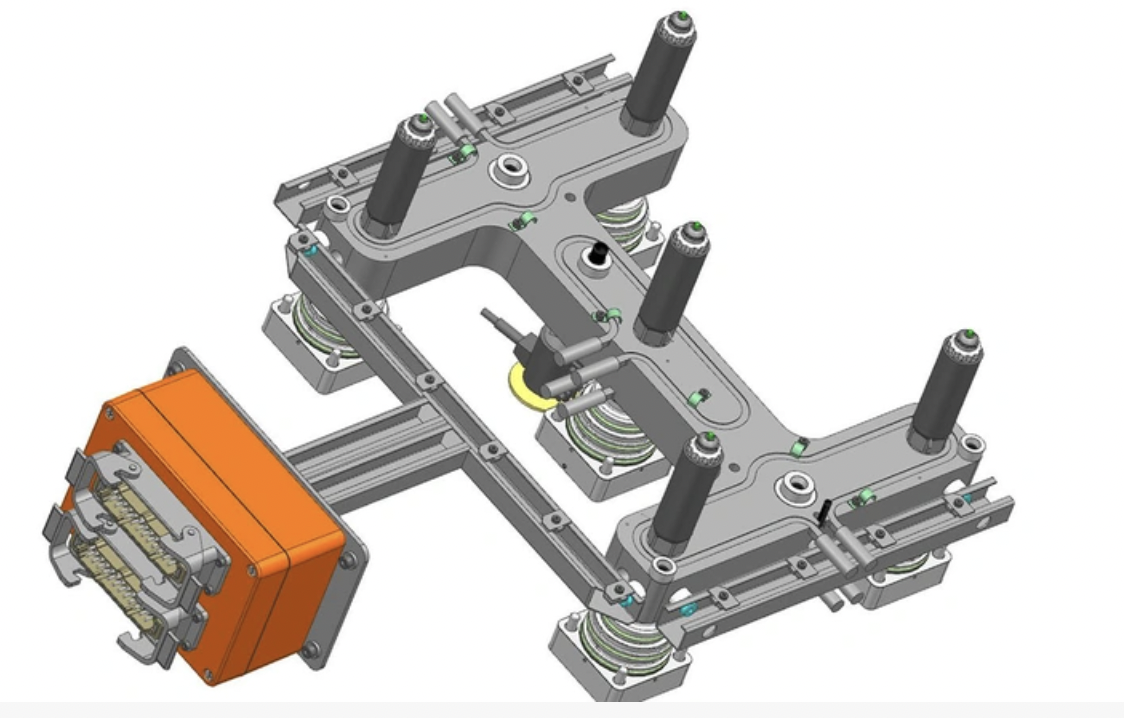

A typical hot runner system consists of several key parts ❤️ :

hashtagManifold: The manifold is a heated distribution system that receives molten plastic from the injection molding machine nozzle and distributes it to individual nozzles leading to each cavity 💭 .

hashtagNozzles: Nozzles are heated components that deliver molten plastic directly into the mold cavities. Each nozzle corresponds to a specific cavity in the mold 📣 .

hashtagHotSprue Bushing: In some systems, a hot sprue bushing is used to connect the machine nozzle to the manifold, ensuring a consistent flow of molten plastic 📯 .

hashtagTemperatureControllers: Temperature controllers are used to regulate the temperature of the hot runner system. Each zone, including the manifold and nozzles, is controlled independently to achieve optimal processing conditions. 🔎

hashtagInsulation: Insulation materials are often used to minimize heat loss and maintain consistent temperature profiles throughout the hot runner system. 💡

hashtagGateInserts: These are components that are part of the mold and are positioned at the gate location. They help control the flow of molten plastic into the mold cavity. ✒ ✏

hashtagHotrunnersystems are commonly used in hashtagmulticavitymolds, large parts, or applications where minimizing material waste and optimizing cycle times are critical. They offer advantages such as improved part quality, reduced production costs, and increased efficiency in high-volume manufacturing. 🔏 ⚒

Tomorrow I will learn more about this, if you are interested please follow and stay tunned, thanks for your time. 🙏 👏

hashtaghotrunnersystems hashtagtoolingmolds hashtagtoolinglearning hashtagmolddesign hashtagstudynotes hashtagplasticinjectionmolds hashtaghotrunner hashtagyudo