Aluminum CNC Machining: Advantages, Disadvantages and Considerations

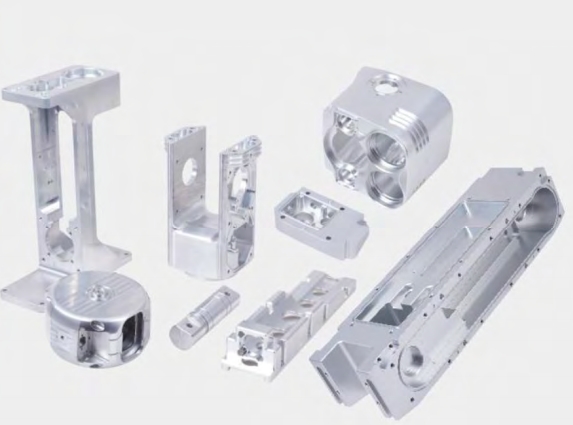

Aluminum almost always appears in the form of alloys. Aluminum elements are everywhere in life. Because of its low density, it can be used to make transportation vehicles (cars, airplanes, trucks, railway vehicles, ships, bicycles, spacecraft, etc.) and also used in packaging. (Aluminum cans, foils, frames, etc.). In our machining and manufacturing industry, aluminum is the most commonly used processing material.

So do you know the advantages and disadvantages of choosing aluminum as a processing material? What should we pay attention to when machining?

There are many advantages and disadvantages to choosing aluminum as a machining material.

Advantage:

Lightweight and high strength: Aluminum alloys have lower density and superior strength, making them suitable for applications requiring lightweight designs.

Corrosion resistance: The aluminum surface forms an oxide film, which has good corrosion resistance and can maintain stability in various environments.

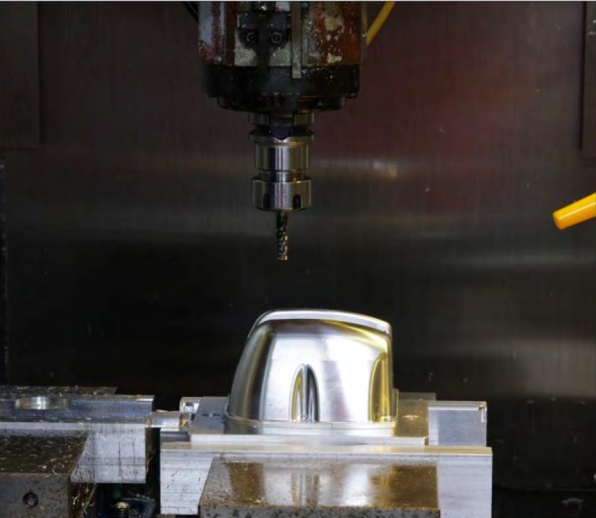

Strong machinability: Aluminum is easy to process and form, and is suitable for various mechanical processing processes, including milling, turning, drilling, etc. The processing time is short, which helps save costs.

Recyclability: Aluminum is a recyclable material and is relatively environmentally friendly during the production process. The waste generated during production can be recycled, helping to reduce resource waste, which is also in line with the environmental protection concept of today's society.

Disadvantage:

Lower hardness: Compared with some higher hardness metals, aluminum has a lower hardness and may not be suitable for some high-wear situations.

Thermal expansion: Aluminum has a large coefficient of thermal expansion and needs to be used with caution in high temperature environments.

Easily scratched: Although an oxide film forms on the aluminum surface, it is still relatively soft and susceptible to scratches.

Difficulty in welding: The welding of aluminum is relatively complex and requires special welding technology.

When machining, we need to pay attention to the following points when choosing aluminum as a processing material:

Suitable cutting tools: Choose cutting tools suitable for aluminum materials to ensure machining results.

Control the cutting speed: Aluminum has good thermal conductivity, so the cutting speed needs to be controlled to avoid excessive heat generated by excessive friction.

Proper Cooling: Using the proper coolant to cool the cutting area helps increase tool life.

Consider thermal effects: In high-temperature processing environments, consider the effects of thermal expansion and material properties of aluminum.

To sum up, aluminum is still one of the most popular materials for CNC machining projects.