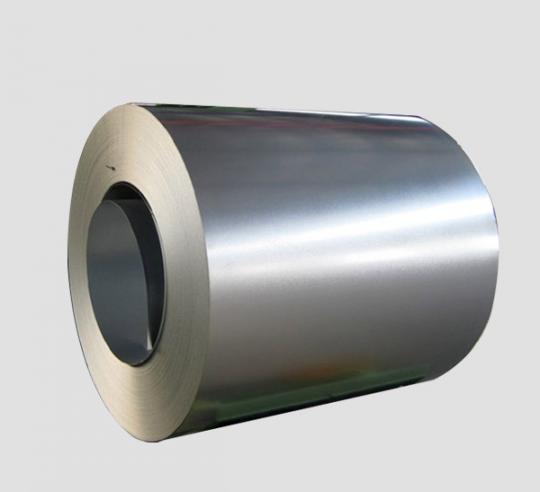

Galvanizing Technology: Endless Possibilities for Protection and Applications

Galvanizing technology, as a method for corrosion prevention and metal protection, has played a significant role in both industrial and everyday life. By depositing a layer of zinc on the metal surface, it not only enhances the material's corrosion resistance but also imparts a wide range of applications. This article explores the fundamental principles of galvanizing technology, various galvanizing methods, and its applications in different fields.

Different Galvanizing Methods

Hot-Dip Galvanizing: Immersing the metal object into molten zinc to create a uniform zinc layer. Commonly used for galvanizing steel products such as steel pipes and structural components in construction.

Cold Galvanizing: Applying a solution or coating containing zinc components to the metal surface. Suitable for fine, small metal products.

Electrogalvanizing: Utilizing electrochemical methods to electrolytically deposit a zinc layer on the metal surface. It offers high control and is suitable for complex-shaped objects.

Advantages:

1.Corrosion Resistance: Galvanization effectively prevents corrosion on the metal surface, extending the material's lifespan. Zinc, acting as a sacrificial anode, forms a barrier between zinc and the metal substrate, reducing the risk of erosion in humid and corrosive environments.

2.Aesthetic Appeal: Galvanization imparts a bright silver coating to the metal surface, enhancing its visual appeal. This makes galvanized metal widely used in areas like construction and furniture where aesthetics matter.

3.Self-Healing: The galvanized layer has self-healing capabilities. If scratches or damage occur during use, zinc will reform a protective layer in the damaged area, maintaining protection of the metal substrate.

4.Environmental Friendly: The galvanization process is relatively environmentally friendly, as it does not involve the use of harmful chemicals used in some other anti-corrosion treatments. Additionally, by extending the lifespan of metal, it reduces resource consumption and waste production.

5.Easy to Process: Galvanized metal materials are relatively soft during processing, making them easy to bend and shape, increasing manufacturing and construction flexibility.

Limitations:

1.Cost: Galvanization is relatively expensive, which may increase the manufacturing cost of products. In some low-cost applications, other anti-corrosion methods may be chosen.

2.Surface Unevenness: Galvanization may lead to uneven coverage on some specially shaped objects. This could be a concern in applications with high aesthetic requirements.

3.Size Limitations: The galvanization process may be limited by the size of the object being treated, and larger or oversized objects may require more expensive treatment methods.

4.Not Suitable for High Temperatures: In high-temperature environments, the zinc layer may become brittle, reducing its protective effectiveness. Therefore, other anti-corrosion methods may need to be considered in high-temperature or fire-risk environments.

5.Not Suitable for Food Contact: Galvanized metals are not suitable for applications involving contact with food, as zinc may leach into the food, posing potential health risks.

Applications

Construction Industry: Galvanized materials find extensive use in construction structures, including galvanized steel pipes and bolts, enhancing the corrosion resistance and lifespan of buildings.

Transportation: Galvanizing technology is applied to automotive components, ship structures, and more, increasing their durability in harsh environments.

Household Items: Galvanized steel is used in the production of furniture, kitchen utensils, and more, providing not only aesthetic appeal but also durability and ease of cleaning.

Power Industry: Structures such as power towers and cable trays are galvanized to improve stability in outdoor environments.

The evolution of galvanizing technology has resulted in its widespread application in various fields. By safeguarding metal from corrosion, galvanizing technology not only enhances the durability of materials but also broadens their applications across different industries. As technology continues to innovate, galvanizing technology will persist in its role of protecting and enhancing material performance in the future.