The importance and application of threads in modern engineering

A thread is a spiral-shaped undulating line or groove evenly distributed along an axis. Threads are widely used in mechanical engineering, construction and other fields for purposes such as connecting, fixing, adjusting and transmitting torque.

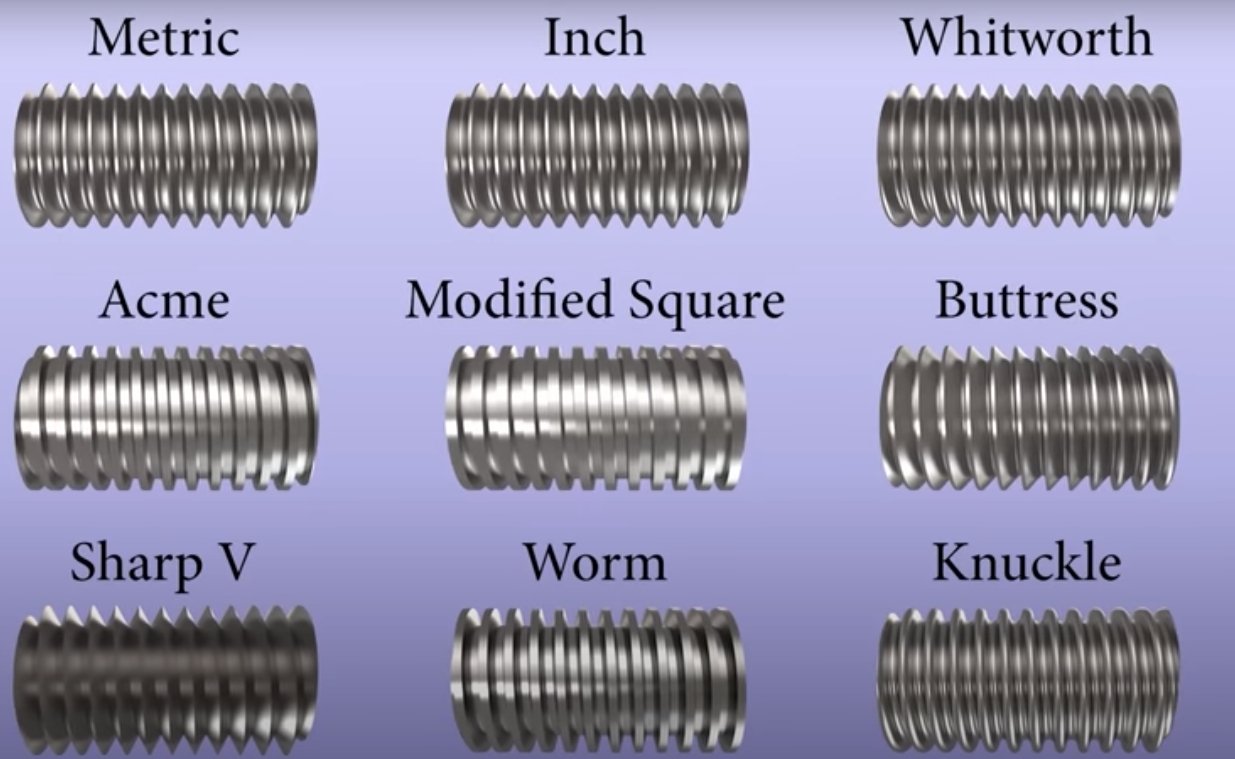

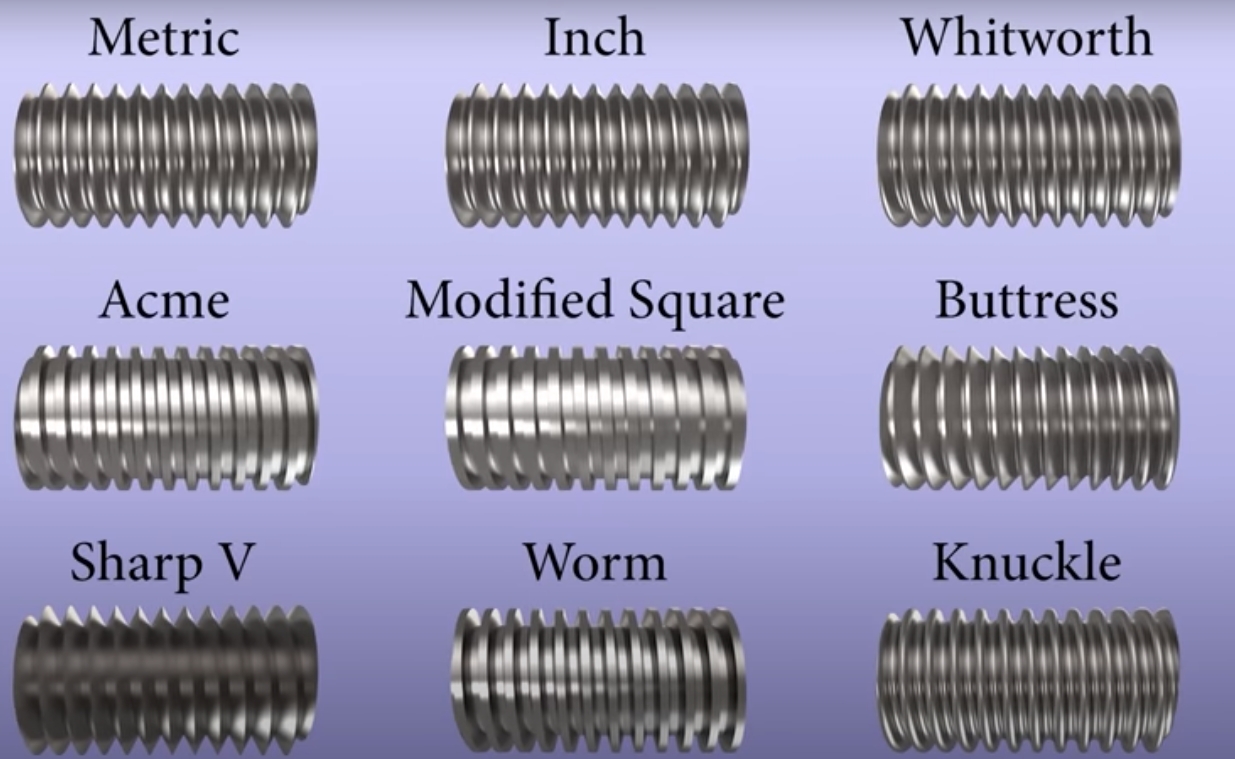

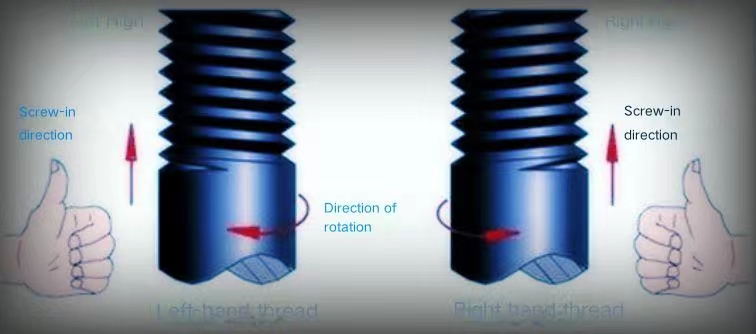

Types of threads:

According to the tooth shape, it can be divided into triangle, trapezoid, rectangle, zigzag and arc thread;

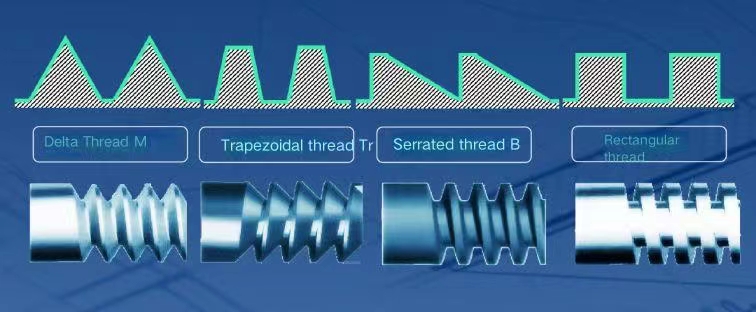

According to the thread direction, it can be divided into left-hand and right-hand;

According to the number of spiral lines, it can be divided into single line and multi-line;

According to the shape of the thread body, it is divided into cylinder and cone.

2. Elements of thread

Threads include five elements: tooth profile, nominal diameter, number of threads, pitch (or lead), and direction of rotation.

1. Tooth shape

In the cross-sectional area passing through the thread axis, the outline shape of the thread is called the profile. There are tooth shapes such as triangle, trapezoid, zigzag, arc and rectangle.

2. Diameter

Threads have major diameters (d, D), medium diameters (d2, D2), and minor diameters (d1, D1). When expressing threads, the nominal diameter is used, and the nominal diameter is the diameter that represents the thread size.

3. Number of threads

Threads formed along one spiral are called single-thread threads, and threads formed by two or more spirals equidistantly distributed along the axial direction are called multi-threads.

4. Pitch and lead

Pitch (p) is the axial distance between two corresponding points on the mid-diameter line of two adjacent teeth.

Lead (ph) is the axial distance between two corresponding points on the mid-diameter line of two adjacent teeth on the same spiral line.

For single-thread threads, lead = pitch; for multi-thread threads, lead = pitch × number of threads.

5. Direction of rotation

Threads that are screwed in when turned clockwise are called right-hand threads;

Threads that are screwed in when turned counterclockwise are called left-hand threads.

Application Areas

1. Threaded Fasteners

Bolts, nuts, and other threaded components are used for assembling mechanical structures. This type of connection allows for convenient disassembly and provides reliable structural support.

2. Threaded Seals

In certain designs, threaded connections can offer effective sealing functions, such as pipe threads. This feature makes threads widely applicable in liquid and gas transmission systems.

3. Manufacturing Processes

Thread manufacturing involves both thread cutting and thread rolling. These manufacturing processes ensure the precision and quality of threads.

Future Developments of Threads

With continuous technological advancements, innovations in thread design and manufacturing are ongoing. The application of new materials and advanced manufacturing techniques will further enhance the performance and reliability of threads in engineering.

As an indispensable connection method in engineering, threads play a crucial role in mechanical, construction, and other fields. A thorough understanding of the fundamental aspects of threads contributes to better application and design of threaded connections, driving advancements in engineering technology.