Explore milling cutters in CNC machining: the magical way to precision cutting

In modern manufacturing, CNC (CNC) processing technology has become an important part of the manufacturing field due to its high precision and efficiency. In CNC machining, milling cutters, as an important cutting tool, play a key role. Let’s take an in-depth exploration of milling cutters in CNC machining and reveal the magic behind their precision cutting.

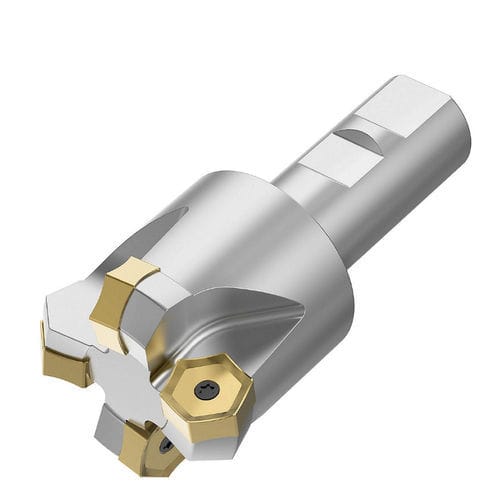

Basic structure of milling cutter

A milling cutter is a tool used for cutting workpieces.

End mill

Face milling cutter

Nested end mill

Ball end mill

Thread milling cutter

Chamfer milling cutter

Milling cutter materials and coatings

The material and coating of a milling cutter significantly affect its performance and service life. Common materials for milling cutters include high-speed steel, carbide, and cubic boron nitride (CBN). In addition, the application of coating enhances the wear resistance and cutting performance of the milling cutter, extending its service life.

Different types of milling cutters do vary in the general tolerances they offer during machining. Tolerance refers to the allowable dimensional deviation range, and its size depends on factors such as process requirements, material characteristics, and processing accuracy.

Precision milling cutters (End Mills): Precision milling cutters are usually used for processing tasks that require high surface quality and dimensional accuracy. They may offer smaller general tolerance ranges, such as between a few microns and tens of microns.

Roughing End Mills: Roughing End Mills are mainly used for fast and large material processing tasks. Because of its faster machining speeds and its main focus on improving tool accuracy with materials, the general tolerance range it offers can be expanded, typically between tens of microns and hundreds of microns.

Ball End Mills: Ball End Mills are often used to process curved surfaces and fillets. Due to the peculiarities of how they are cut, a smaller general tolerance range may be provided, similar to precision milling cutters.

Flat End Mills: Flat end mills are commonly used for surface machining and grooving. Its general tolerance range depends on the specific processing requirements and material properties, and may range from tens to hundreds of microns.

Milling cutter applications

Milling cutters are widely used in CNC machining to machine a variety of materials, including metals, plastics, and wood. They play a vital role in industries such as automotive manufacturing, aerospace, electronics and medical devices. The precision cutting capabilities of milling cutters facilitate the efficient and precise machining of complex parts.

With the continuous development of manufacturing technology, milling cutter technology continues to advance. The application of new materials, new coatings, and new processing techniques will further improve the performance and efficiency of milling cutters and bring more possibilities to the manufacturing industry. In the future, we can play a more important role of milling cutters in CNC machining and help the manufacturing industry move to a higher level.