What are knockout rod and safety pins in tooling mold?

For beginners delving into the world of tooling molds, understanding the fundamental components is key to grasping the intricacies of mold design and operation. So let's dive in.

One such component that holds significant importance in the mold-making process is the KO (Knockout) rod. KO rods play a crucial role in the ejection system of injection molds, facilitating the removal of molded parts from the mold cavity.

Despite its seemingly simple function, the KO rod is an indispensable part of mold design, ensuring efficient production and smooth operation. Let's delve deeper into the world of KO rods and unravel their significance in the realm of tooling molds.

Positive ejection, also known as knockout (K.O) return, is a mechanism used in tooling molds to push or eject molded parts out of the mold cavity after the molding process is completed.

It ensures that the finished parts are smoothly released from the mold, allowing for efficient production and preventing damage to the parts or the mold itself.

The usage of positive ejection or K.O return is essential in molds where the molded parts have complex shapes, deep undercuts, or tight tolerances that make it difficult for the parts to be released naturally from the mold. By applying controlled force through ejector pins or other mechanisms, positive ejection ensures that the parts are ejected reliably and consistently.

Now, regarding K.O Rod and K.O Extension, here is some info:

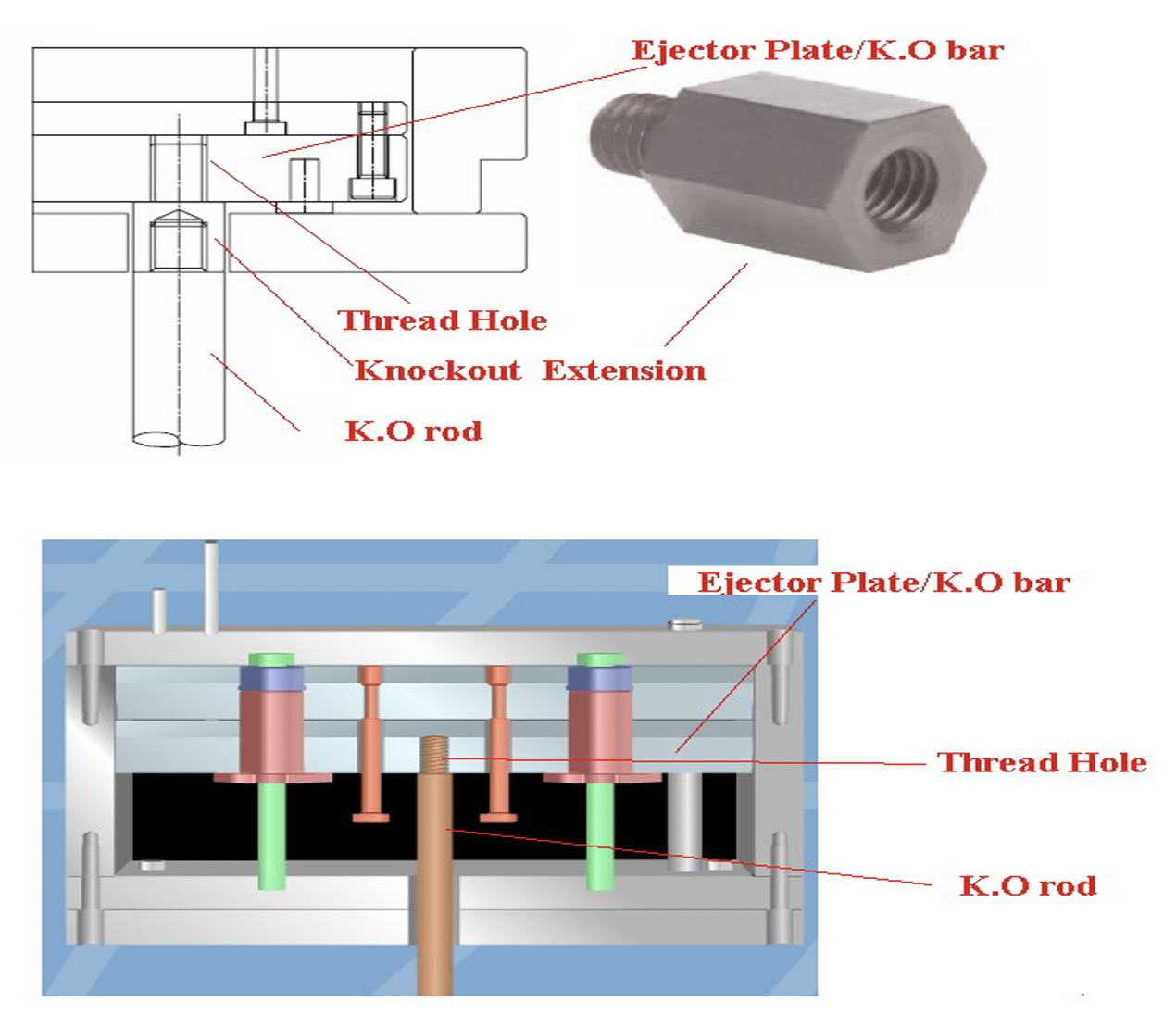

- K.O Rod: This refers to the rod or shaft used to transmit the ejection force from the mold's ejection system (such as hydraulic cylinders or mechanical actuators) to the ejector pins or other ejection components within the mold. The K.O rod moves linearly to activate the ejection mechanism and push the parts out of the mold.

- K.O Extension: This term typically refers to an additional component or extension attached to the K.O rod to reach deeper into the mold cavity. In molds with complex geometries or deep features, a standard-length K.O rod may not provide sufficient reach to eject the parts effectively. In such cases, a K.O extension is added to extend the reach of the ejection system, ensuring that all parts are properly ejected from the mold.

In summary, positive ejection (K.O return) is crucial for ensuring efficient and reliable part ejection in tooling molds, especially for complex parts or molds with deep features. The K.O rod and K.O extension are components of the ejection system that transmit force and provide reach, respectively, to facilitate effective part ejection.

After exploring the essential role of KO rods in tooling molds, it's time to turn our attention to another vital component: the safety pin. While KO rods play a significant role in facilitating the ejection of molded parts, safety pins serve a similar function but with distinct characteristics and applications.

Often overlooked but crucial to the mold design, safety pins ensure the safe and efficient ejection of parts, contributing to the overall functionality and reliability of the molding process. Join us as we delve into the world of safety pins and uncover their importance in the realm of tooling molds.

A safety pin in tooling molds refers to a mechanical component designed to provide additional safety measures during the operation of the mold. Safety pins are often used to prevent accidental movement or operation of certain mold components, particularly in situations where there is a risk of injury to personnel or damage to the mold itself.

The primary purpose of a safety pin in a tooling mold is to secure movable parts or mechanisms in a fixed position, preventing them from moving unintentionally during mold setup, maintenance, or operation. This helps ensure the safety of operators and technicians working with the mold and minimizes the risk of accidents or damage.

Safety pins are typically inserted into designated holes or slots in the mold structure to lock specific components in place. They may be used to secure elements such as mold inserts, slides, cores, or ejector pins, depending on the design and requirements of the mold.

In addition to providing safety benefits, safety pins also offer convenience and ease of use by allowing operators to quickly and securely immobilize or release mold components as needed during setup or maintenance procedures.

Overall, safety pins play an essential role in maintaining a safe working environment in tooling mold operations, helping to prevent accidents and ensure smooth and efficient mold operation.

In conclusion, KO rods and safety pins are two essential components in the intricate world of tooling molds. While KO rods facilitate the smooth ejection of molded parts, safety pins provide an added layer of security and reliability to the molding process.

Together, these components ensure the efficient operation of the mold, resulting in high-quality and defect-free parts.

By understanding the functions and applications of KO rods and safety pins, mold designers and manufacturers can optimize their processes and deliver superior products to their clients.

For further inquiries or discussions on tooling mold components, feel free to contact us at danny@opro-tech.com.

Thank you for exploring these fundamental elements with us!