Key Components of Injection Molding: A Deep Dive into Cylinder Mechanisms

Key Components of Injection Molding: A Deep Dive into Cylinder Mechanisms

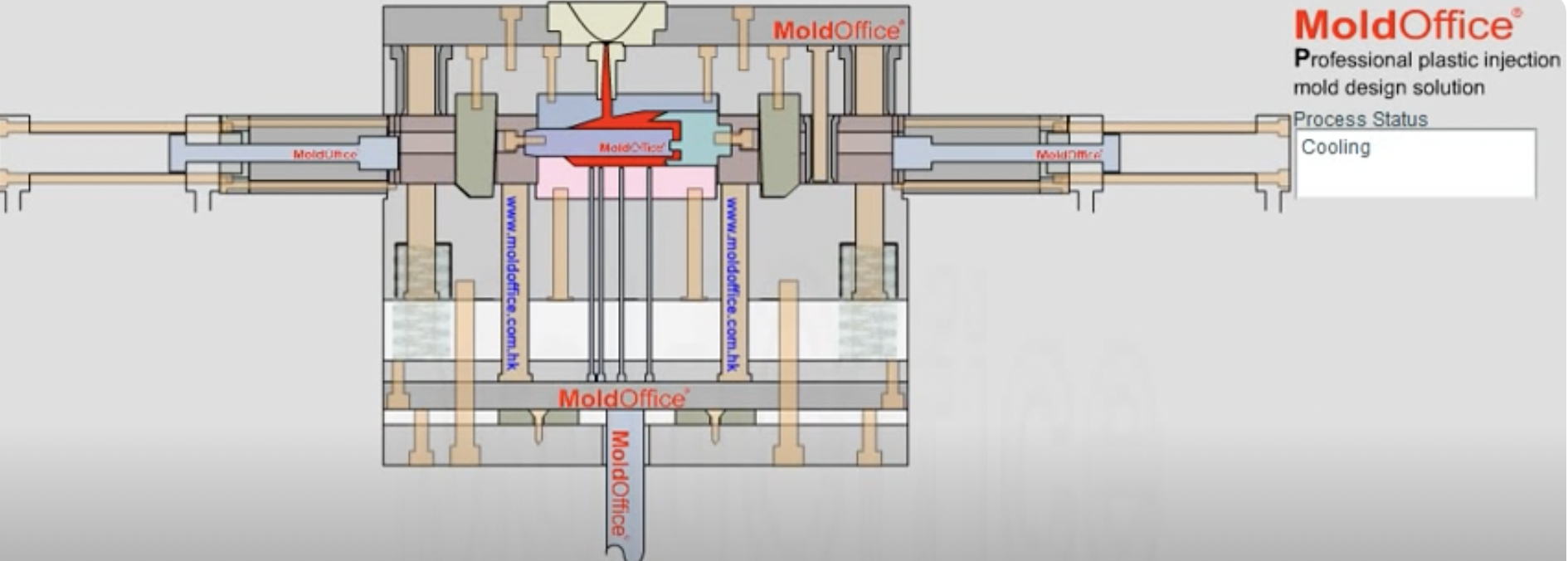

In plastic injection molding, a cylinder is a critical component of the mold that plays an essential role in the process. Here are the key aspects of what a cylinder does in plastic injection tooling:

1. Injection Cylinder:

- Function: The injection cylinder, also known as the injection unit, is responsible for melting the plastic material and then injecting it into the mold cavity. It includes a reciprocating screw inside a heated barrel.

- Components:

- Screw: Rotates to melt the plastic pellets and moves forward to inject the molten plastic.

- Heaters: Surround the barrel to heat the plastic to the appropriate temperature.

- Nozzle: Connects the cylinder to the mold, allowing the molten plastic to flow into the mold cavity.

2. Hydraulic Cylinder:

- Function: Hydraulic cylinders are used to operate various moving parts of the mold, such as core pulls, ejector pins, and slides. They provide the necessary force to move these components accurately.

- Components:

- Piston: Moves within the cylinder to create the required motion.

- Hydraulic Fluid: Pressurized fluid that drives the piston.

- Control Valves: Regulate the flow of hydraulic fluid to control the movement of the piston.

3. Core Pull Cylinders:

- Function: Core pull cylinders are specific hydraulic cylinders used to retract and extend the cores of the mold. These cores create internal features or undercuts in the molded part that cannot be achieved with a simple two-part mold.

- Components:

- Core Rod: Connected to the piston, moves in and out to form the internal features.

- Cylinder Body: Houses the piston and controls its movement.

4. Ejector Cylinders:

- Function: These cylinders are used to push the finished part out of the mold after the plastic has solidified. They operate the ejector pins or plates.

- Components:

- Ejector Pins/Plates: Mechanisms that directly contact the molded part to eject it.

- Piston: Drives the ejector pins or plates forward.

5. Locking Cylinders:

- Function: In some molds, hydraulic cylinders are used to lock the mold halves together during the injection process to ensure proper alignment and sealing.

- Components:

- Locking Mechanism: Engages with the mold halves to secure them.

Summary:

Cylinders in plastic injection molding are crucial for various functions, including melting and injecting the plastic, moving mold components, forming internal features, ejecting parts, and locking the mold. They ensure precise and efficient operation of the injection molding process, resulting in high-quality molded parts.

Cylinders are not necessarily a key part of every plastic injection tooling mold, but they are essential components in many molds, particularly those with more complex designs or specific functionality requirements. Here's a more detailed explanation:

1. Basic Molds:

- Two-Plate Mold: In a simple two-plate mold, which is used for straightforward parts without complex geometries, cylinders might not be required. These molds consist of a stationary half and a movable half, and the part is ejected using basic ejector pins or plates without the need for additional hydraulic or pneumatic cylinders.

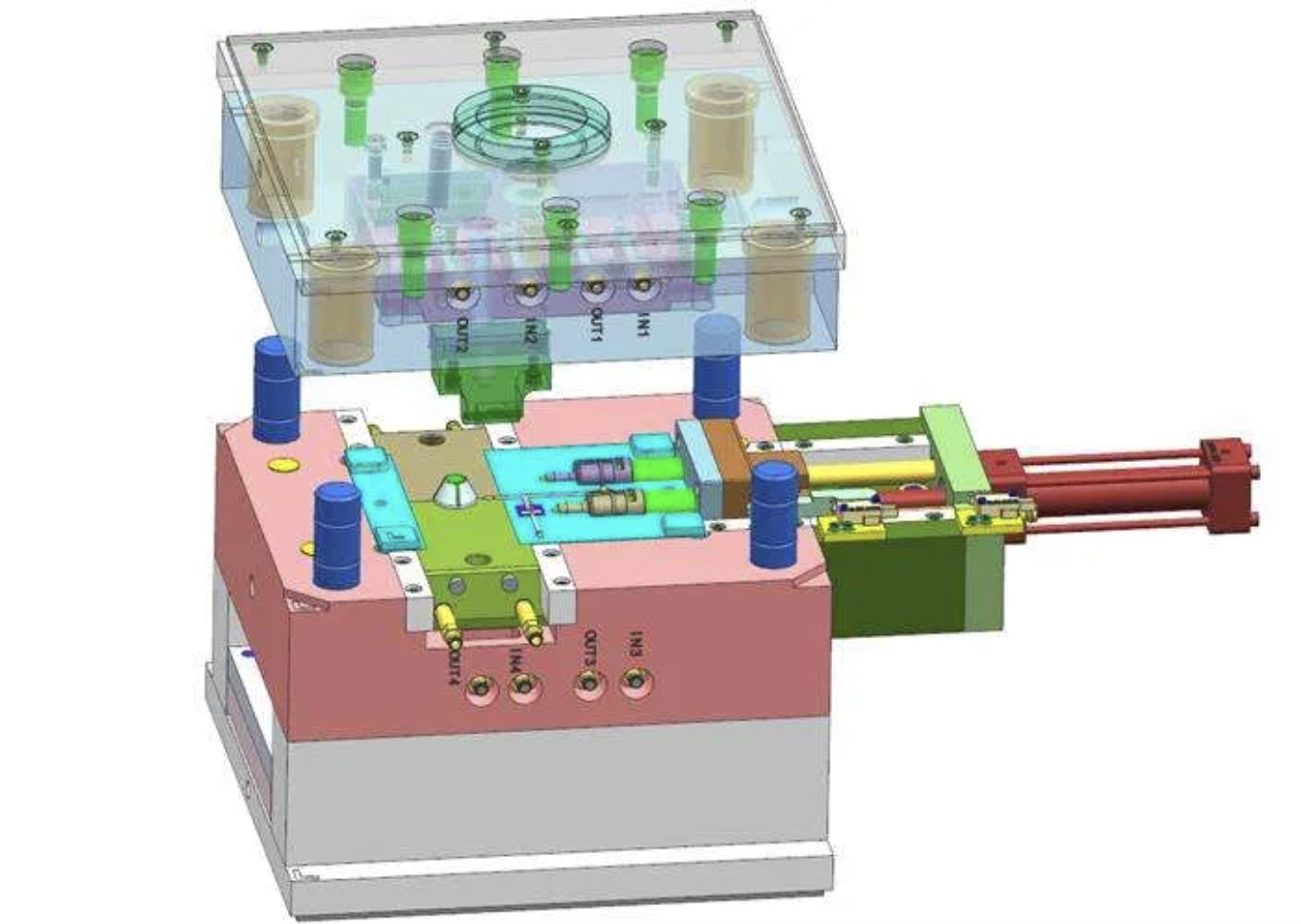

2. Complex Molds:

- Three-Plate Mold: This type of mold is used for parts requiring more complex ejection mechanisms, often involving additional plates. While cylinders are not always necessary, they can be used to control the movement of these plates.

- Molds with Cores and Slides: When parts have undercuts, side holes, or other complex geometries, cylinders (often hydraulic or pneumatic) are essential to operate core pulls and slides. These components allow the mold to produce intricate features that cannot be achieved with a basic two-plate mold.

- Stack Molds: Used to increase production efficiency by molding multiple parts in a single cycle, stack molds often require cylinders to manage the movement of various mold sections and ensure proper alignment and operation.

3. Specialized Functions:

- Core Pull Cylinders: When internal features or side actions are needed, core pull cylinders are critical for moving the cores in and out of the mold cavity.

- Ejector Cylinders: In more complex molds, ejector cylinders are used to precisely control the ejection of parts, ensuring they are removed without damage.

- Valve Gate Control: In hot runner systems, cylinders can be used to control valve gates, regulating the flow of molten plastic into the mold cavities.

Conclusion:

While cylinders are not a key part of every tooling mold, they become crucial components in molds that require advanced features, precise movements, and the ability to produce complex part geometries. For simpler molds, basic mechanical actions may suffice, but as the complexity and functionality of the mold increase, the reliance on cylinders (hydraulic, pneumatic, or mechanical) grows significantly.

Here is an in-depth look at hydraulic and pneumatic cylinders, their uses, advantages, and differences:

Hydraulic Cylinders

Overview

Hydraulic cylinders use pressurized hydraulic fluid (usually oil) to produce linear motion and force. They are commonly used in heavy-duty applications where substantial force is required.

Components

- Cylinder Barrel: The main body that houses the piston and hydraulic fluid.

- Piston: The movable component that divides the cylinder into two chambers and translates hydraulic pressure into linear motion.

- Piston Rod: The rod attached to the piston that extends and retracts to perform work.

- Seals: Ensure that hydraulic fluid does not leak from the cylinder.

- End Caps: Secure the ends of the cylinder barrel and provide mounting points.

- Hydraulic Fluid: Typically oil, used to transfer force from the pump to the piston.

Applications in Injection Molding

- Core Pulls: Used to retract and extend cores to create internal features or undercuts in the molded part.

- Ejector Systems: Operate ejector pins or plates to push out the finished part.

- Slide Movements: Control the movement of slides in the mold to allow for the molding of complex geometries.

Advantages

- High Force Capability: Can generate large amounts of force, making them ideal for heavy-duty applications.

- Precision: Offer precise control over movement and positioning.

- Smooth Operation: Provide smooth and consistent motion.

Disadvantages

- Complexity: More complex and require more maintenance than pneumatic systems.

- Cost: Generally more expensive due to the components and the need for a hydraulic power unit.

- Potential for Leaks: Hydraulic fluid can leak, which requires maintenance and can cause contamination.

Pneumatic Cylinders

Overview

Pneumatic cylinders use compressed air to produce linear motion and force. They are typically used in applications where lower force and faster speeds are sufficient.

Components

- Cylinder Barrel: The main body that houses the piston and compressed air.

- Piston: The movable component that divides the cylinder into two chambers and translates air pressure into linear motion.

- Piston Rod: The rod attached to the piston that extends and retracts to perform work.

- Seals: Ensure that air does not leak from the cylinder.

- End Caps: Secure the ends of the cylinder barrel and provide mounting points.

- Compressed Air: The working fluid, usually provided by an air compressor.

Applications in Injection Molding

- Light-Duty Core Pulls: Used for less demanding core pull applications.

- Part Ejection: Can be used to operate ejector systems for pushing out parts.

- Automation Systems: Frequently used in automated mold operations where rapid and repetitive movements are needed.

Advantages

- Simplicity: Simpler design and easier to maintain compared to hydraulic systems.

- Cost: Generally lower cost due to fewer components and the use of compressed air.

- Speed: Can operate at higher speeds for rapid movements.

- Clean Operation: Air is clean and does not pose a contamination risk.

Disadvantages

- Lower Force Capability: Cannot generate as much force as hydraulic cylinders, limiting their use in heavy-duty applications.

- Less Precision: Generally offer less precise control over movement compared to hydraulic systems.

- Compressed Air Requirements: Require a source of compressed air, which can add to operational costs.

Comparison

- Force Generation: Hydraulic cylinders can generate much higher forces compared to pneumatic cylinders.

- Precision and Control: Hydraulic systems offer more precise control, making them suitable for applications requiring high accuracy.

- Speed: Pneumatic cylinders can operate at higher speeds, making them ideal for applications requiring rapid movements.

- Maintenance: Hydraulic systems are more complex and require more maintenance, whereas pneumatic systems are simpler and easier to maintain.

- Cost: Hydraulic systems tend to be more expensive due to the components and hydraulic fluid, whereas pneumatic systems are generally more cost-effective.

In summary, the choice between hydraulic and pneumatic cylinders in injection molding depends on the specific requirements of the application, including the required force, precision, speed, and budget.

Dan

Business development manager

Phone: +86 134 1699 5669

Skype: danny@opro-tech.com

Factory add: No 39, Zhen an west road, Changan town , Dong guan city, China.

Injection Mold / CNC Machining / 3D Printing / Prototyping / Sheet Metal