From Powder to Part: The Rise of Metal 3D Printing Technologies

3D printing with metals is definitely a thing, but it’s quite different from standard polymer-based methods like SLS (Selective Laser Sintering). Unlike resin printing, metal 3D printing is mostly done using powders or wires that are melted or sintered.

Metal 3D printing has rapidly evolved from a niche technology into a powerful manufacturing solution used across aerospace, medical, tooling, and high-performance industries.

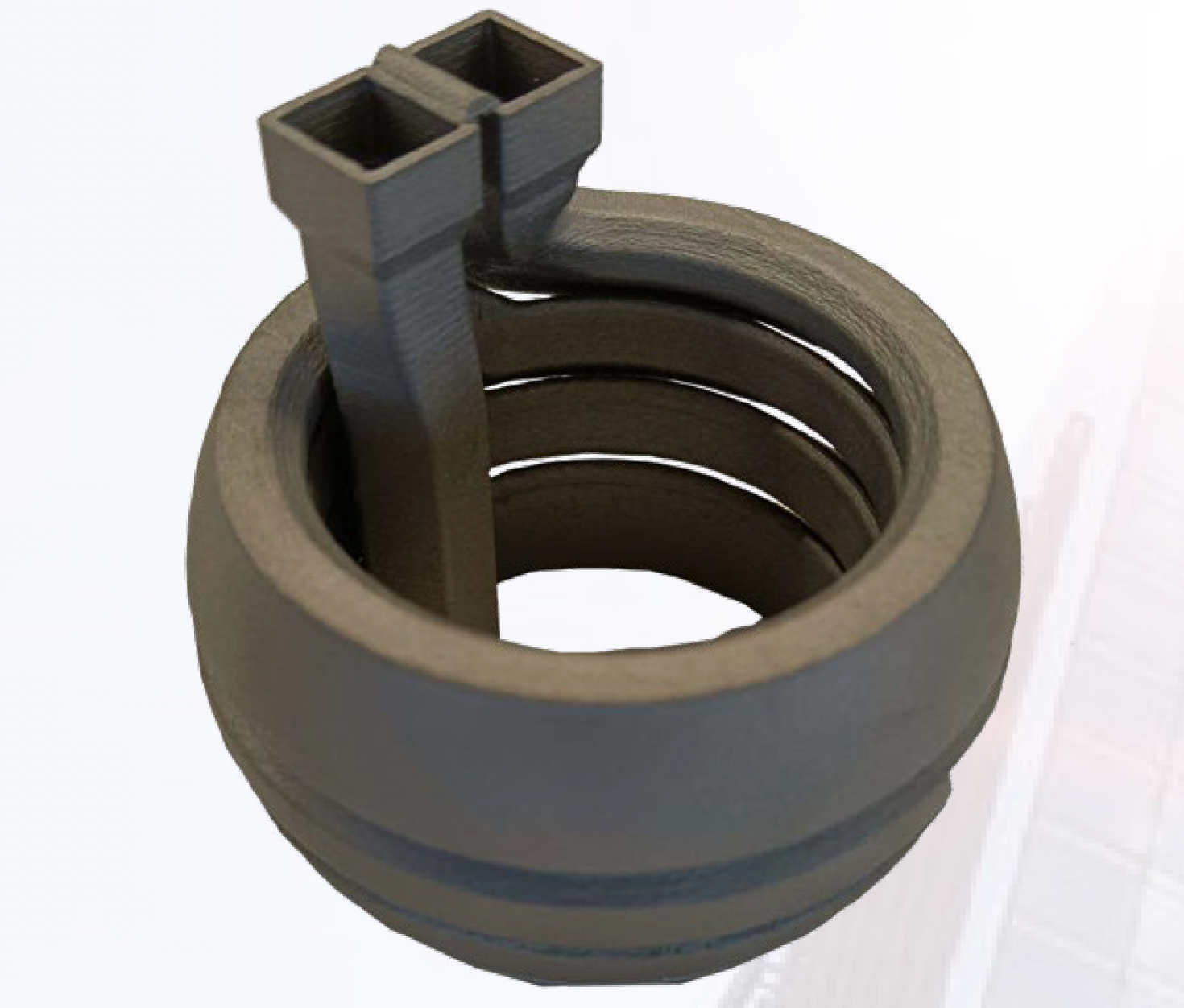

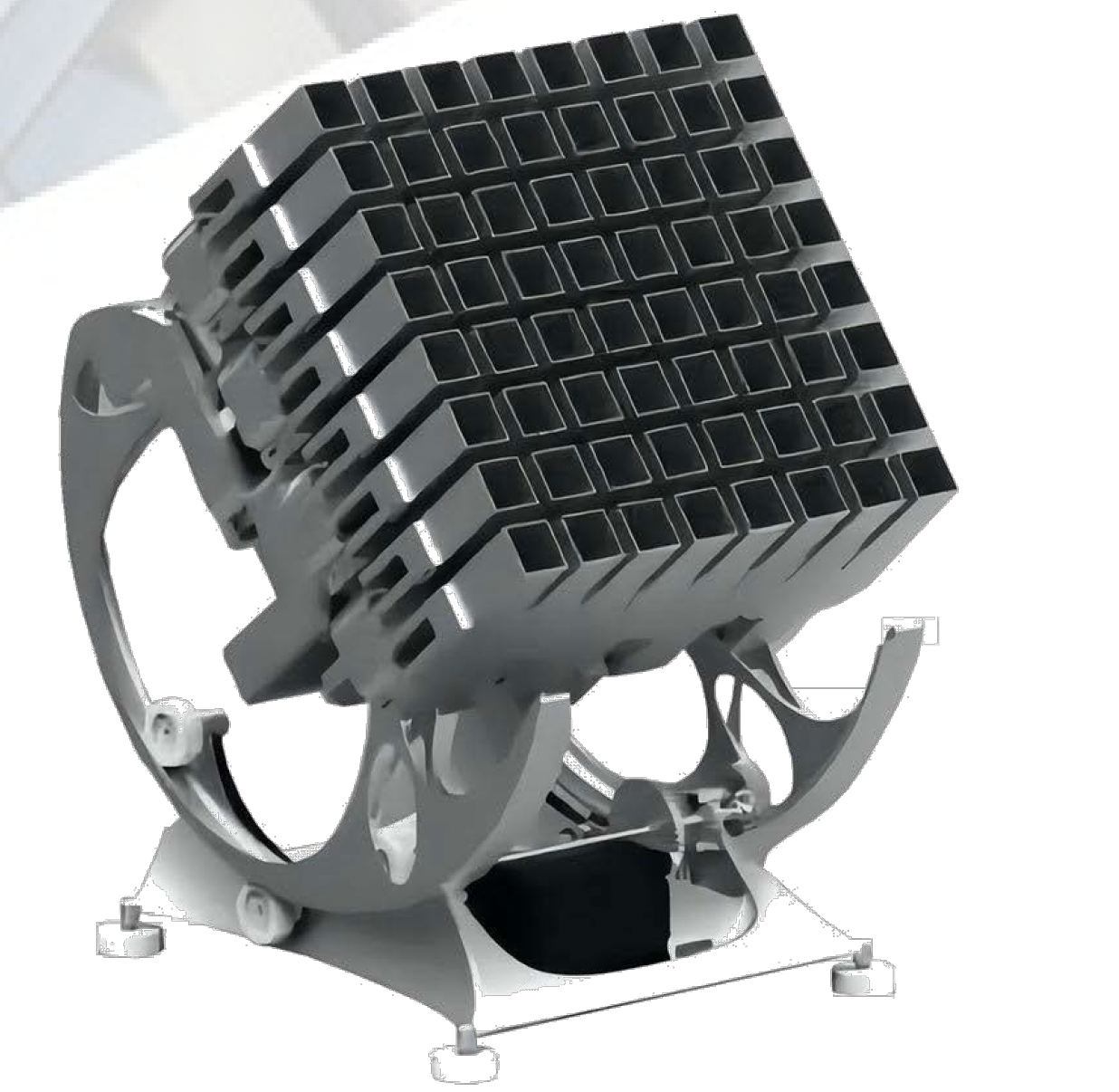

Unlike traditional machining, which removes material from a solid block, metal 3D printing builds parts layer by layer—unlocking shapes and internal structures that were once impossible to manufacture.

As companies push for lighter, stronger, and more efficient components, 3D metal printing is becoming an important complement to conventional machining and a key driver of innovation in modern manufacturing.

Here’s a breakdown of metals you can 3D print today:

1. Steels

- Stainless Steel (304, 316, 17-4PH, etc.) → strong, corrosion-resistant, used in tools, prototypes, end-use parts.

- Tool Steel → for molds, dies, cutting tools, wear-resistant parts.

- Maraging Steel → very strong, used in aerospace, automotive, and tooling.

2. Titanium

- Ti6Al4V (Grade 5) → lightweight, strong, corrosion-resistant, commonly used in aerospace, medical implants, and high-performance applications.

3. Aluminum

- Lightweight, good strength-to-weight ratio, corrosion-resistant. Popular in aerospace, automotive, and heat-sensitive parts.

4. Copper & Copper Alloys

- Pure Copper → excellent thermal/electrical conductivity, tricky to print with lasers (needs special high-power setups).

- Bronze / Brass / CuAlloys → easier than pure copper, used for decorative or functional parts.

5. Nickel Alloys

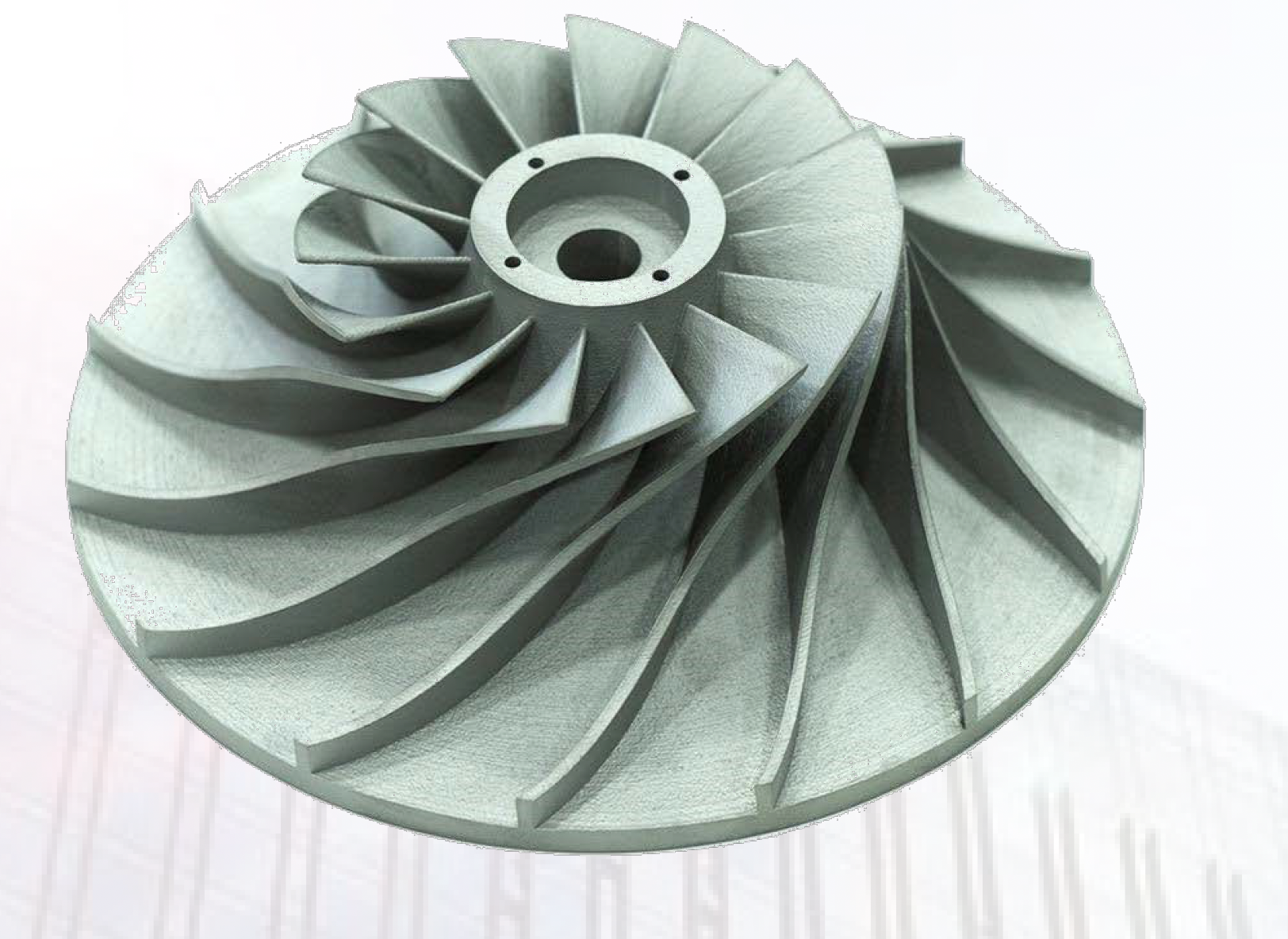

- Inconel (Ni-based superalloys) → extremely heat-resistant, used in turbines, aerospace, and engines.

6. Cobalt-Chrome

- Strong, wear-resistant, biocompatible → dental implants, medical devices, aerospace parts.

7. Precious Metals

- Gold, Silver, Platinum → mainly for jewelry, dental crowns, and small decorative parts using binder jetting or laser melting.

3D printing vs CNC machining for metals

1. Cost Comparison

2. Rule of Thumb

· 3D printing is cost-competitive when:

o The part is very complex, hard to machine, or has internal features.

o You need small quantities or prototypes.

· CNC machining is cheaper when:

o Parts are simple shapes or medium to large production.

o You need tight tolerances or a good surface finish.

3D Metal Printing Market

1. Current Market Use

· Aerospace & Defense: Widely used for turbine components, brackets, and lightweight structural parts. Complexity and weight savings make it ideal.

· Medical & Dental: Implants, prosthetics, surgical guides—especially titanium and cobalt-chrome—because they can match complex anatomy.

· Automotive & Motorsport: Low-volume performance parts, prototypes, and some tooling components.

· Tooling & Molds: Conformal cooling channels in injection molds or die-casting dies.

· Jewelry & Custom Items: Gold, silver, and platinum printing for complex designs.

2. Limitations Preventing Wider Adoption

· Cost: Metal powders and machines are expensive, so it’s mostly for high-value parts.

· Speed: Printing is slower than CNC for simple parts.

· Post-Processing: Supports removal, heat treatment, surface finishing—adds time and cost.

· Material Limitations: Not every alloy prints easily (copper and some aluminum alloys are tricky).

3. Bottom Line

· 3D metal printing is growing fast, especially in industries where complexity, light weight, or customization justifies the cost.

· But for mass production of simple parts, traditional machining, casting, or forming is still dominant.

While metal 3D printing is not a replacement for CNC machining, it fills a valuable space where complexity, customization, and performance matter most.

As materials, machines, and processes continue to improve, the technology will become even more accessible and capable.

For manufacturers and engineers, understanding when and how to leverage metal 3D printing is now an essential skill—one that opens the door to new design freedoms, faster development cycles, and next-generation products.