Compression, Extrusion, or Injection? Choosing the Right Process for Rubber and TPU Parts

When you happened to see the word “EPDM,” and do you got curious? — What exactly is this material? At Opro tech, we often deal with plastic injection molding parts, so at first, you might think as EPDM just another type of plastic. But after digging deeper, you will find that EPDM actually belongs to the rubber family — it’s flexible, weather-resistant, and usually produced by compression or extrusion molding instead of plastic injection.

The more we learned, the more interesting it became to see how different materials require completely different molding technologies.

🧩 What is an EPDM product?

EPDM stands for Ethylene Propylene Diene Monomer, a type of synthetic rubber (elastomer).

It’s widely used for parts that need flexibility, weather resistance, and durability, such as:

- Sealing gaskets and O-rings

- Weatherstrips for doors and windows (especially in automotive)

- Vibration dampers and hoses

- Waterproof membranes

So when people say “EPDM product”, they usually mean a rubber part made by compression molding, injection molding (rubber type), or extrusion, using EPDM material.

⚙️ Difference between EPDM products and plastic injection molding parts

🧠 In short:

· EPDM = rubber part, soft and flexible, mainly for sealing or damping functions.

· Plastic injection part = hard structural part, mainly for shape, fit, or mechanical strength.

They’re made with different materials and molding methods, though sometimes both may be used in one assembly — for example, a plastic housing with an EPDM gasket inside.

🧱 1️⃣ Common manufacturing methods for EPDM

✅ Most EPDM parts are made by:

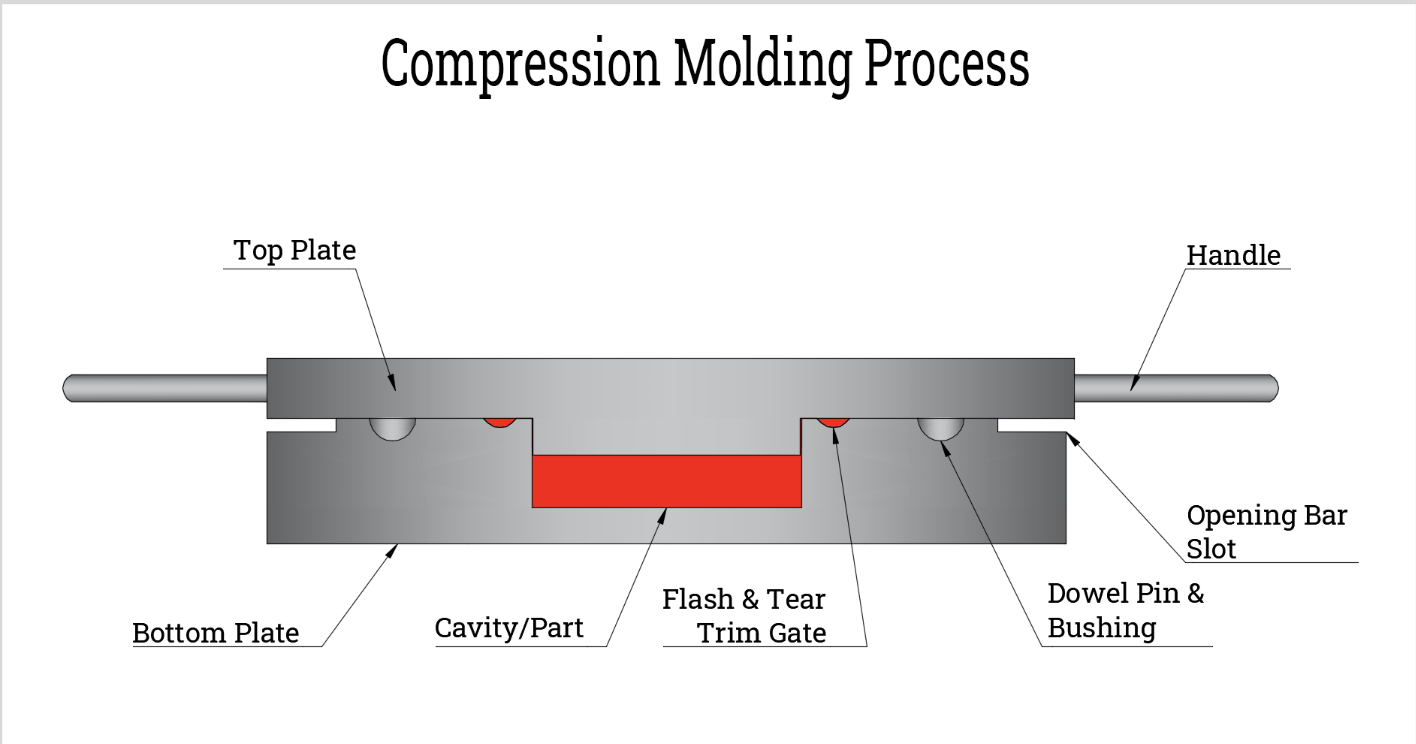

- Compression molding → For seals, gaskets, O-rings, and small rubber components.

- Extrusion → For continuous profiles like weatherstrips, door/window seals, tubing, etc.

These two are indeed the most common and cost-effective processes for EPDM, since the material is rubbery and doesn’t flow like thermoplastic.

⚙️ 2️⃣ EPDM injection molding — yes, possible but less common

EPDM can also be injection molded, but this refers to rubber injection molding, not plastic injection molding.

The difference is:

- Rubber injection molding uses unvulcanized EPDM compound injected into a heated mold, where it cures (vulcanizes) into its final shape.

- Plastic injection molding uses melted thermoplastic resin, which cools down to form a solid part.

🧩 3️⃣ Typical products made by EPDM injection molding

When EPDM is injection molded, it’s usually for high-precision or complex rubber parts, for example:

- Automotive parts:

- Sealing grommets, plugs, and bellows

- Suspension bushings

- Wire harness boots

- Electrical & mechanical sealing parts:

- Connector seals, cable entries, waterproof gaskets

- Household appliances:

- Door seals, anti-vibration pads, flexible dampers

Injection molding is chosen when the shape is too complex for extrusion and requires consistent precision (e.g., multiple cavities, tighter tolerance).

🧠 4️⃣ Summary for easy explanation

🧱 1️⃣ ✅ Most rubbers and silicones are made by compression molding or transfer molding (and sometimes extrusion).

Because:

· They start as uncured (raw) material, kind of like dough.

· They need heat + pressure in the mold to vulcanize (cure) into their final elastic form.

· The viscosity is too high to “flow” like plastic, so rubber injection molding is slower and more expensive, used only for more complex parts.

⚙️ 2️⃣ The main rubber forming technologies

compression is still the most widely used, but LIM is very popular for liquid silicone products.

🧪 3️⃣ Hardness difference (Shore A vs Shore D)

· Rubbers and silicones: usually Shore A 20–80 (soft, flexible)

· TPU (Thermoplastic Polyurethane): can range from Shore A 70 to Shore D 75 (becomes much harder)

So when you mentioned TPU 95, that’s likely Shore A 95 or even Shore D 50, which is already much harder than traditional rubber — that’s why TPU can be injection molded like plastic.

Rubber = chemical curing (vulcanization)

TPU = physical cooling (thermoplastic)

🔍 4️⃣ Summary — quick way to explain to clients

In the end, learning about EPDM, silicone, and TPU reminded me that materials define the way we make things.

Rubber and silicone need curing and special molding processes, while thermoplastics like TPU can go straight into injection molding.

Understanding these differences isn’t just technical knowledge — it helps us choose the right material for the right function, design parts more efficiently, and even communicate better with clients.

Every material has its strengths, and knowing them well makes us better engineers, problem-solvers, and creators.

Factory add: No 39, Zhen an west road, Changan town , Dong guan city, China.