Why can't the thread pitch be reduced if it is large?

The products we delivered to customers a few days ago, we received feedback from them today, pointing out that the specifications they required were M81, and what we provided was M8*1.25mm. Customers stated that they were unable to rework because the thread spacing was too large. I have done in-depth research on screws and nuts, but I still have a question: Why can’t M81.25 products be reworked to M8*1mm specifications?

Screws are a common fastening element used to fasten objects together or connect components. The main parts of a screw include the thread, head, shaft and tip. Here is an overview of these sections:

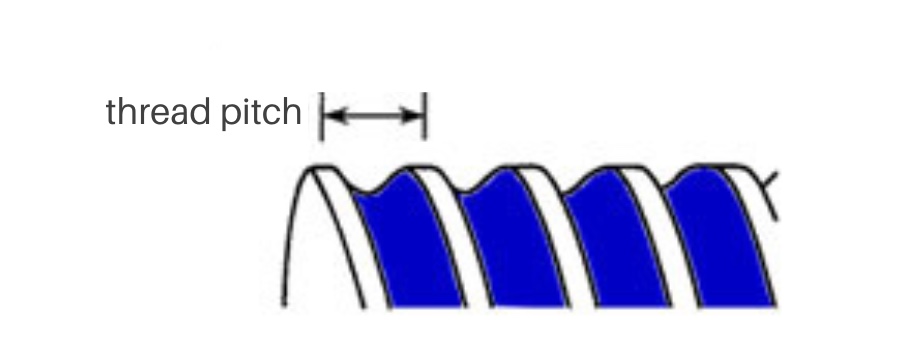

Threads: Threads are one of the most important features of a screw and are usually spiral-shaped grooves or projections. It allows screws to be easily screwed into or out of nuts or connected parts. Threads come in different types and standards, such as metric threads and imperial threads.

Head: The head of a screw is usually the side of the tool (such as a screwdriver or wrench) used to turn the screw. Heads are available in various shapes, including hexagonal, cross-shaped, flat head, etc., to suit different tools and application needs.

Shaft: The shaft is the part that connects the head to the threads and is usually an elongated cylindrical structure. The diameter and length of the shaft can vary depending on the size and purpose of the screw.

Tip: The tip of a screw is usually tapered or tapered to make it easier to penetrate and enter objects. The design of the tip can also affect the drive performance of the screw.

A nut is a fastening element used to mate with a screw. It is usually used to connect two or more parts, and its relative position to the screw can be adjusted by rotation. The main parts of the nut include the following aspects:

Threaded Hole: The nut has a threaded hole on the inside that mates with the threads of the screw. This threaded hole allows the nut to rotate on the screw, creating a connection between the two.

Shape: The shape of the nut can have different designs, the most common is the hexagonal nut, also known as the hexagonal nut. In addition to this, there are square, round and other shapes of nuts to suit different tools and applications.

Nut Face: One side of the nut is usually flat, this is the side that comes into contact with the tool to allow for rotation and adjustment. Some nuts may also have grooves on the flat surface to match the shape of the tool to improve stability during the connection.

Nut Height: Nut height refers to the overall length of the nut, which is usually designed to meet the needs of a specific application. In some cases, a thinner nut is required to fit into limited space, while in other cases a taller nut may be required to provide greater connection force.

Why can't the pitch be reduced if it is too large?

I found that there is relatively little information about thread pitch modification on the Internet. This may be because such operations are not common in actual production, and there are also some technical and cost challenges.

On the one hand, modifying the thread pitch may involve precision machining of the product, requiring highly specialized equipment and technology. Even small modifications can be complicated by adjusting process and equipment settings. This increases the difficulty and risk of the operation.

On the other hand, cost is also a consideration. Modifications to an already manufactured product can require the investment of significant resources, including specialized equipment, labor, and time. Such modifications will most likely result in an overall cost higher than remanufacturing the product to specification, so remanufacturing may be more attractive from an economic perspective.

This experience also reminds us that it is crucial to ensure the accuracy and control of details during the production process. At the beginning of product design and manufacturing, adequate planning and quality control can effectively avoid such problems and avoid unnecessary waste of costs and man-hours.