What is sprue, sprue bushing and nozzle in hot runner system?

🤔 🤔 Sprue, sprue bushing, and nozzle—terms that have sparked my curiosity in the realm of tooling molds.

To unravel their mysteries, I've dived into the vast realm of online resources and sought insights from my technical colleagues, believing that the best teacher is often a combination of Google searches and the knowledge shared by experienced peers. 😘 😘

However, if you happen to possess a particularly enlightening explanation or insights into these components and their interplay within a tooling mold, I would be immensely grateful for your contribution. Thank you a million times over! 🙆♀️ 🙆♀️

Below information I got from website for reference.

Well actually I kind of think the information from Internet is not that accurate. As per my understanding, a nozzle is essentially the heated rod responsible for delivering molten plastic into each mold cavity. On the other hand, the sprue bushing seems to be akin to a nozzle bushing, serving as the bushing for the nozzle. However, my certainty in these definitions is not absolute. I'm eager to hear your thoughts on this. Looking forward to your insights. Thanks! 🤔 🤔

📣 In a tooling mold, a sprue bushing and a nozzle play crucial roles in the injection molding process.

🔔 Sprue Bushing:

🔉 Function: The sprue bushing is a component that forms the entry point for molten plastic into the mold cavity. It provides a passage for the plastic material to flow from the injection molding machine into the mold.

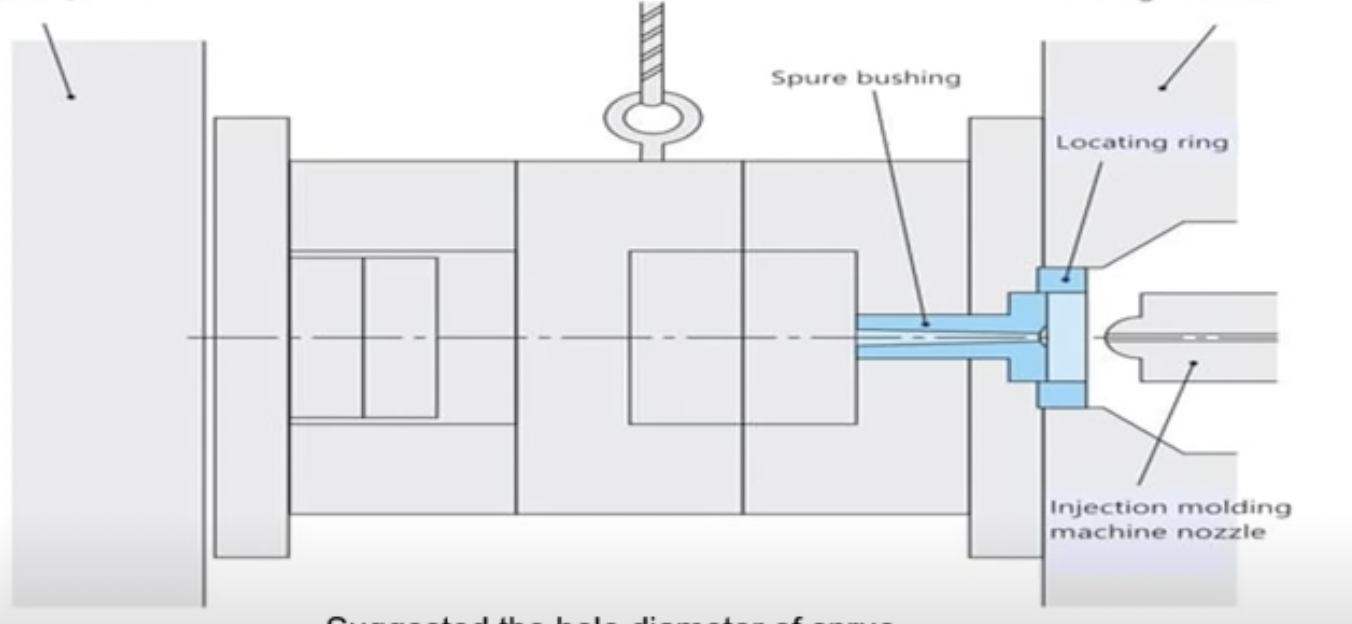

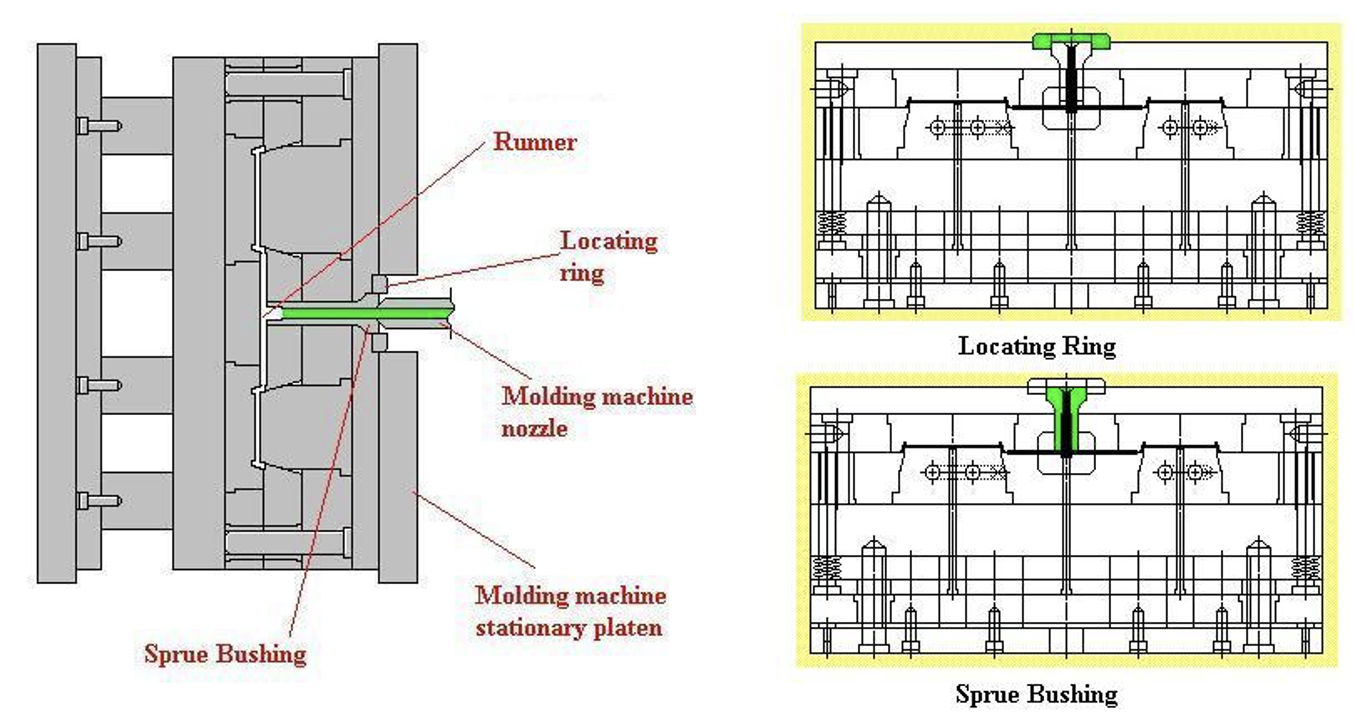

🖌 Location: Typically, the sprue bushing is located at the center of the mold, and it is connected to the machine's nozzle.

📣 Nozzle:

💡 Function: The nozzle is a component of the injection molding machine that delivers the molten plastic material into the mold. It is responsible for injecting the plastic material with precision and control.

🖋 Location: The nozzle is part of the injection unit of the molding machine and is positioned in close proximity to the sprue bushing.

Relationship:

🤔 🤔 The nozzle of the injection molding machine and the sprue bushing of the mold work together to facilitate the injection process. When the machine injects molten plastic into the mold, the plastic material flows through the nozzle and into the sprue bushing.

😐 😐 The sprue bushing acts as a passage for the molten plastic to enter the mold cavity. It directs the flow of plastic material and helps distribute it to the various runners and gates within the mold.

In summary, the sprue bushing and nozzle are integral components that collaborate to ensure the controlled and accurate injection of molten plastic into the mold, initiating the molding process.

Whaat do you think ? ❓ ⁉ Thank you.

Below updated on 3th Jan, thanks for your interests.

🤣 😂 Hahaha, I used to be uncertain about the #nozzle, #spruebushing, and #locatingring, kind of stupid though, but after these days of learning, I've become more familiar with these crucial components.

Now, I'd like to share a clarification about the nozzle, sprue bushing, and locating ring: 👩🔧 👩🔧

🌈 🌈 The nozzle is a component of the #injectionmolding machine that delivers the molten plastic material into the mold. It is responsible for injecting the plastic material with precision and control. And it’s a very important part of #hotrunner system.

🙋♀️ 🙋♀️ The sprue bushing features a central hole through which the injection nozzle of the molding machine delivers molten #plastic. It is designed to withstand the pressure and temperature of the injected material.

🧠 🧠 The role of the locating ring is to ensure that when assembling the mold to the injection molding machine, the sprue bushing of the mold is horizontally and perfectly aligned with the nozzle position of the injection molding machine. Therefore, a positioning element is provided for the mold. A locating ring is added outside the mold sprue bushing.

🤨 🤨 This ring is the same size as the front template hole of the injection molding machine. By fitting this ring into place, it ensures that the position of the mold sprue bushing aligns perfectly with the nozzle position of the machine.

Feel free to provide the specific content you'd like to share, thanks.

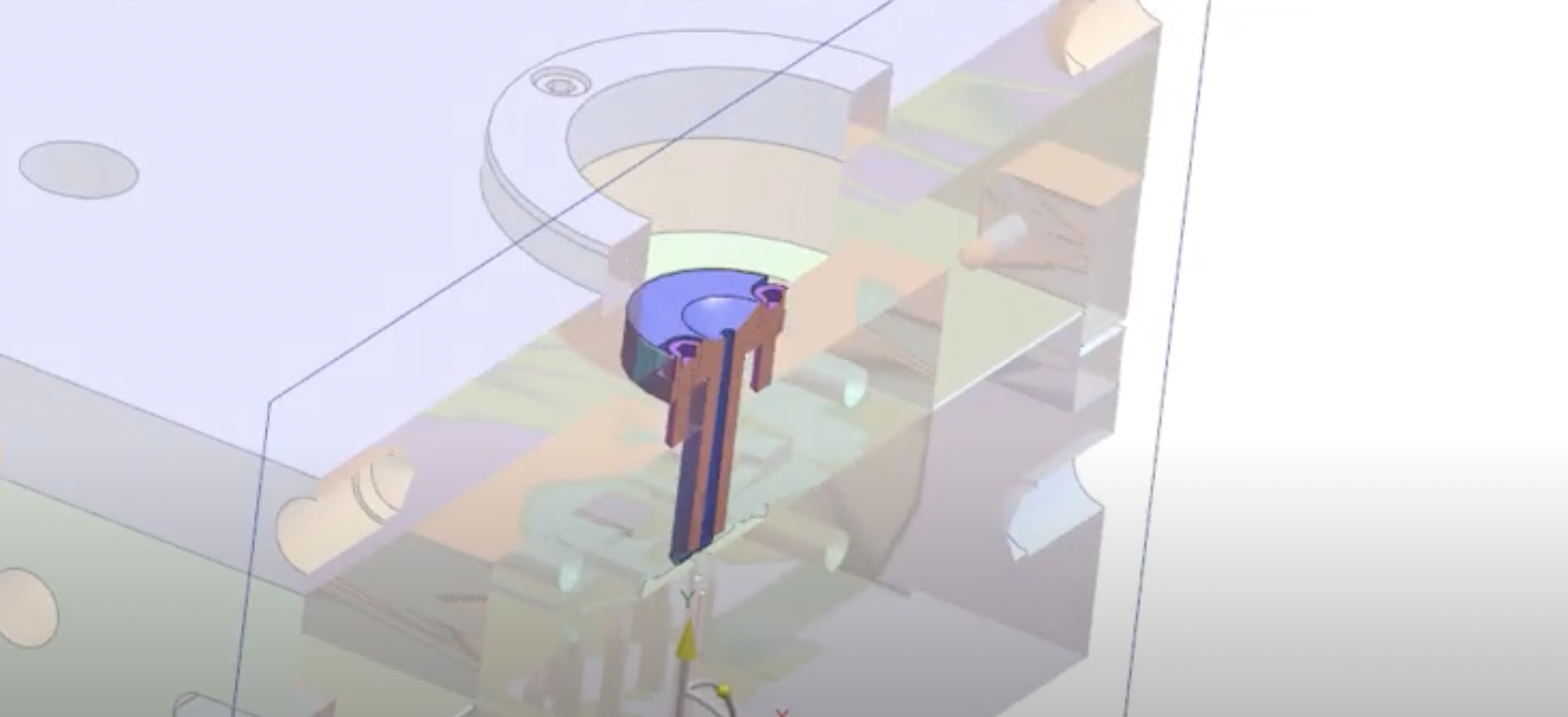

🔧🔥 Exciting Behind-the-Scenes Look: Assembling a Hot Runner System into a Mold! 🔥🔧

Ever wondered how a hot runner system gets seamlessly integrated into a mold for plastic injection molding? 🤔 🎥

Click my latest video where the skilled technician assembling the manifold of a hot runner system into a mold 💡🌐✨

Thank you for watching !

https://youtu.be/Jy1zSWDztgQ

#InjectionMolding #HotRunnerSystem #Manufacturing #BehindTheScenes #Innovation #EngineeringExcellence