How does water line cooling system work in a mold?

😑 😘 😘 Thanks to the internet, I've been able to acquire a wealth of technical knowledge about #toolingmolds.

😘 A particular YouTube channel, "Injection Molding Skills&More," provided insightful videos, offering basic information about water cooling line systems.

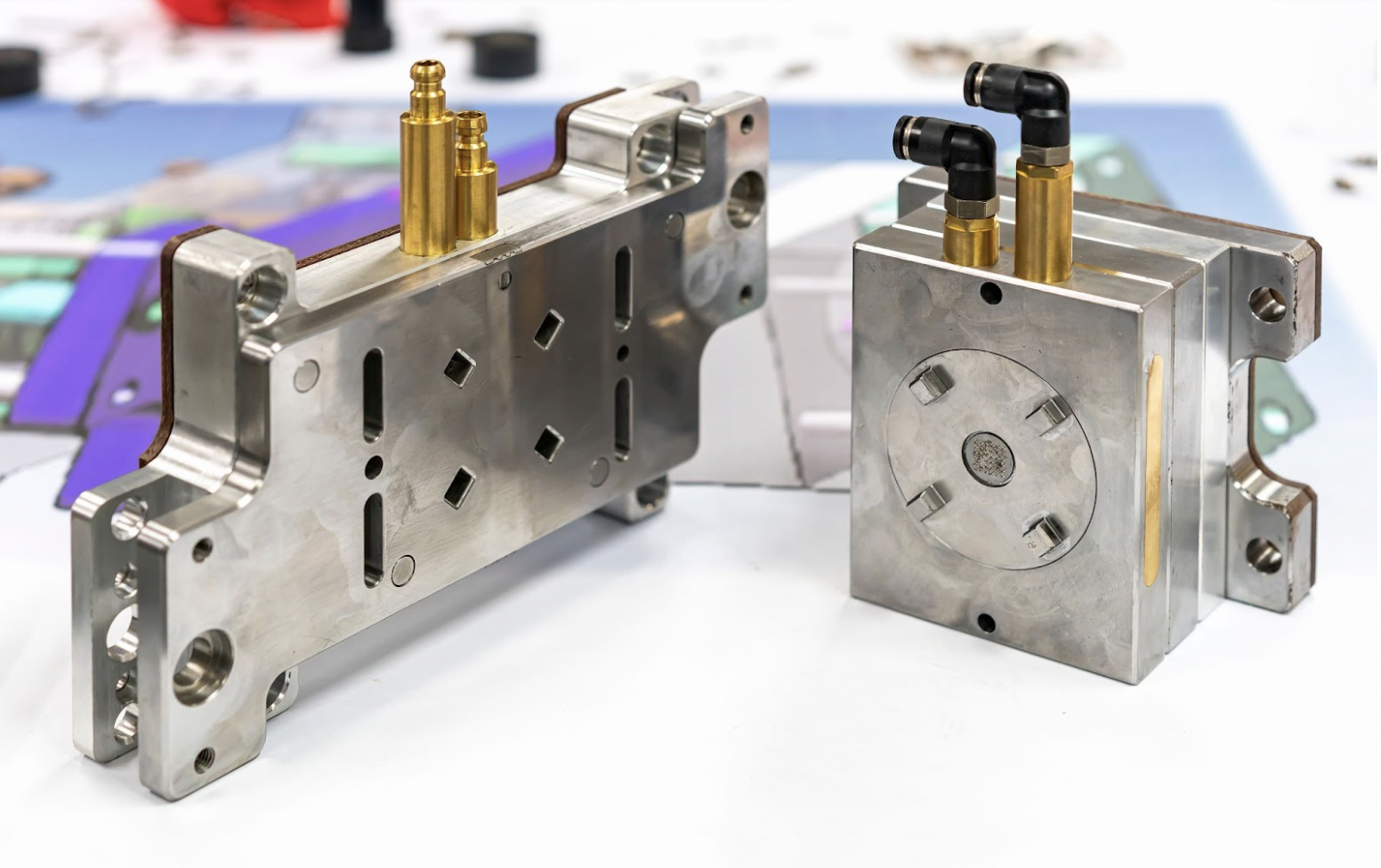

This content emphasized the crucial role played by #waterbaffles and #waterdiagrams in tooling molds. Here are my study notes for reference. 👍 👍

https://www.youtube.com/watch?v=QfZ23lJmS2I

📣 📣 A #watercooling system in a tooling mold is a mechanism designed to manage and control the temperature of the mold during the injection molding process. It is essential for maintaining consistent and optimal temperature levels in the mold to ensure the quality and efficiency of the production process. Here's how it generally works:

Cooling Channels:

Inside the mold, there are strategically placed cooling channels or passages. These channels are designed to circulate coolant, usually water, to absorb heat generated during the molding process.

Temperature Control:

The flow of coolant through these channels is controlled by a cooling system. The system can adjust the temperature of the coolant to achieve the desired mold temperature.

Heat Absorption:

As the molten plastic material is injected into the mold, it heats the mold surfaces. The circulating coolant in the cooling channels absorbs this heat, preventing the mold from overheating.

Maintaining Consistent Temperature:

The cooling system continuously monitors and adjusts the coolant temperature to maintain a consistent temperature throughout the mold. This is crucial for achieving uniform cooling and preventing issues like warping, shrinkage, or uneven part quality.

Efficient Cooling:

Efficient cooling is essential for achieving faster cycle times. Once a cycle is completed, the mold needs to be quickly cooled to solidify the plastic part, allowing for its ejection from the mold.

Cycle Time Optimization:

By controlling the mold temperature through the water cooling system, manufacturers can optimize cycle times, enhance productivity, and achieve better overall efficiency in the injection molding process.

The water cooling system plays a critical role in ensuring the longevity of the mold, preventing thermal stress, and maintaining the integrity of the molded parts. It is an integral component in the injection molding process, contributing to the production of high-quality and consistent plastic components.

✅ ✅ In tooling molds, water baffles and water diagrams are elements of the water cooling system, which is crucial for controlling the temperature of the mold during the injection molding process. Let's explore each term:

🔰 🔰 Water Baffles:

Definition: Water baffles are #components or structures within the mold that are strategically placed to control the flow and direction of cooling water.

Purpose: The primary purpose of water baffles is to enhance the uniform distribution of cooling water throughout the mold. By directing the water flow in specific patterns, baffles help ensure consistent cooling across different areas of the mold.

🔰 🔰 Water Diagram:

Definition: A water diagram is a schematic representation or drawing that illustrates the layout and configuration of the cooling channels, baffles, and connections within the mold.

Purpose: The water diagram serves as a visual guide for understanding the flow of cooling water throughout the #mold. It indicates the placement of water channels, the connections between various cooling passages, and the overall design of the cooling system.

🔔 🔔 Key Points:

Both water baffles and water diagrams contribute to optimizing the #cooling efficiency of the mold.

The proper design of water baffles ensures that cooling water reaches all parts of the mold uniformly, preventing hot spots and promoting consistent part quality.

The water diagram aids in the manufacturing and maintenance processes by providing a clear representation of the cooling system's layout.

👩💻 👩💻 In summary, water baffles and water diagrams are essential elements in the overall water cooling system of tooling molds. They play critical roles in achieving optimal mold temperature control, which, in turn, influences the quality and efficiency of the injection #molding process.

#toolingsolutions #moldings #waterline #watercoolingsystem #waterbaffles #waterdiagram