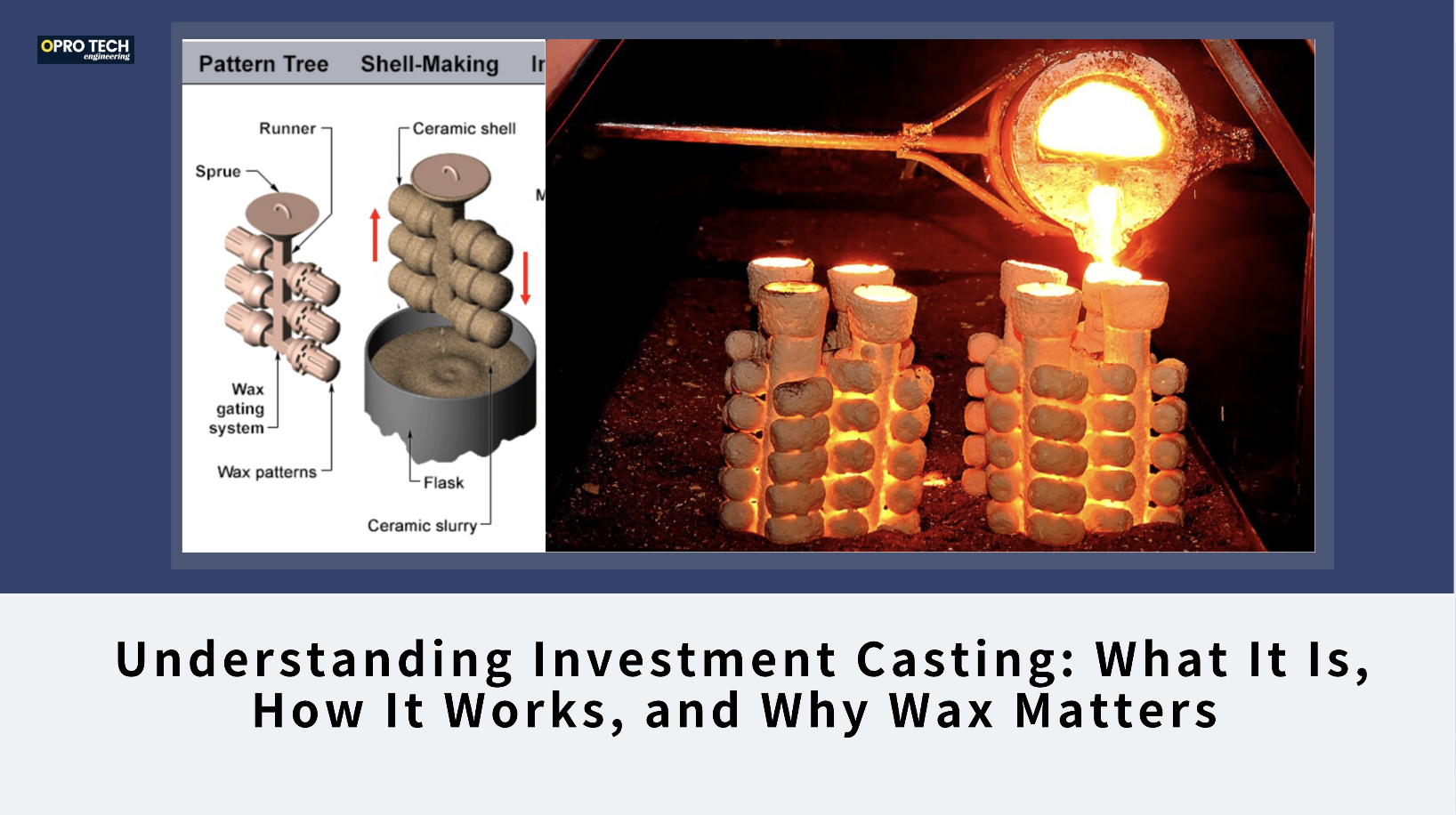

Understanding Investment Casting: What It Is, How It Works, and Why Wax Matters

Introduction: "Why Can Wax Be Used to Make Steel Parts?" That’s exactly the question I asked myself the first time I heard about investment casting. I’ve worked with many manufacturing processes like...

![[Case Study] Shipping Plastic Parts with Embedded Magnets: The Unexpected Challenge We Faced with Magnetism Test Requirements](/uploads/opro-engineering/20250603/3891dded-67f0-41da-b59e-e6c1979829fe.png)