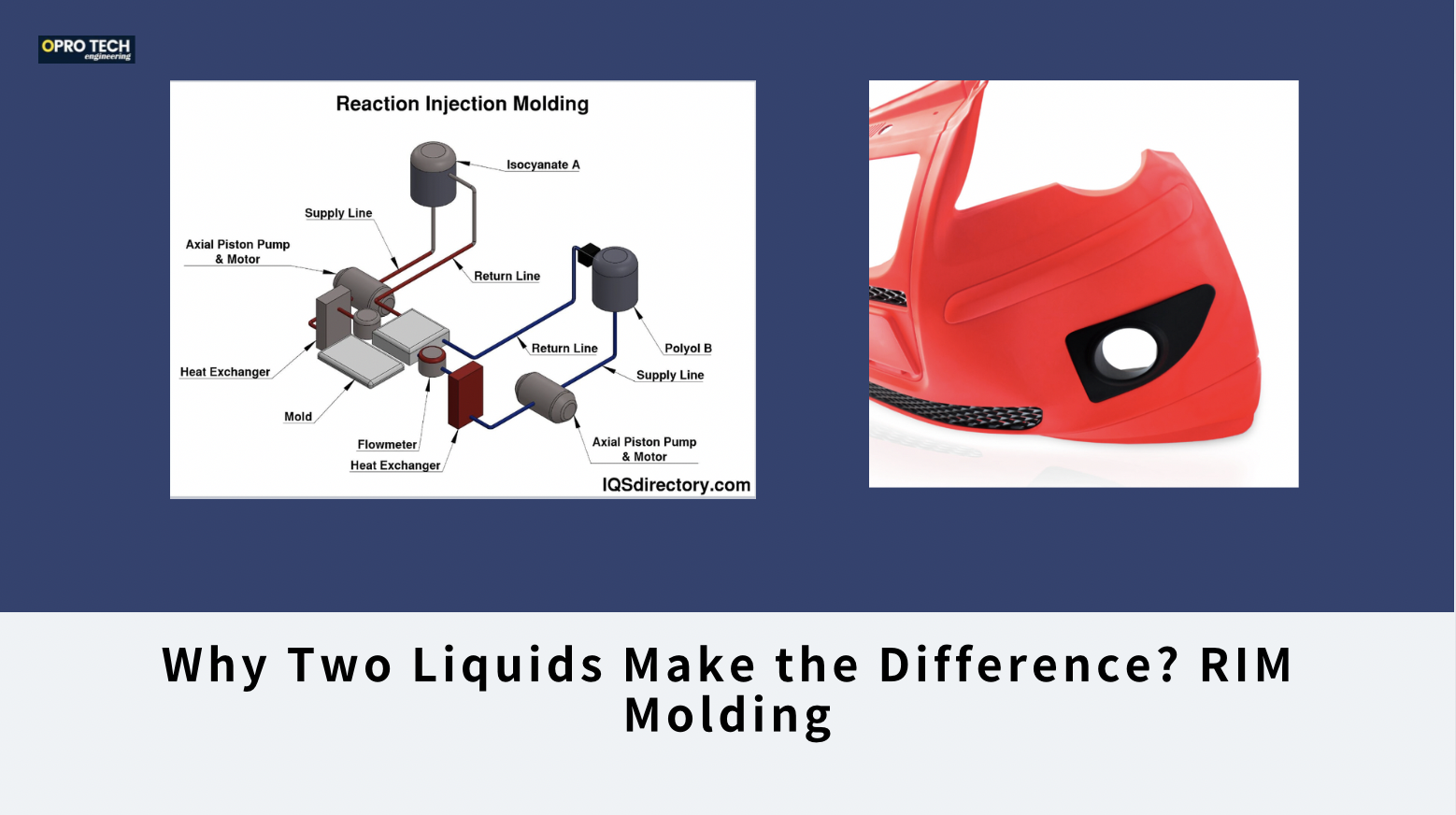

Unlocking the Science Behind Reaction Injection Molding: Why Two Liquids Make the Difference

"Unlocking the Science Behind Reaction Injection Molding: Why Two Liquids Make the Difference" In the world of advanced manufacturing, Reaction Injection Molding (RIM) stands out as a unique process...